Device and method for preventing workpiece with plane top from slipping on roller transmission line

A transmission line, anti-slip technology, applied in the direction of conveyor control device, transportation and packaging, conveyor, etc., can solve the problems of roller and workpiece slipping, small positive pressure, slipping, etc., to increase friction and save manual operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

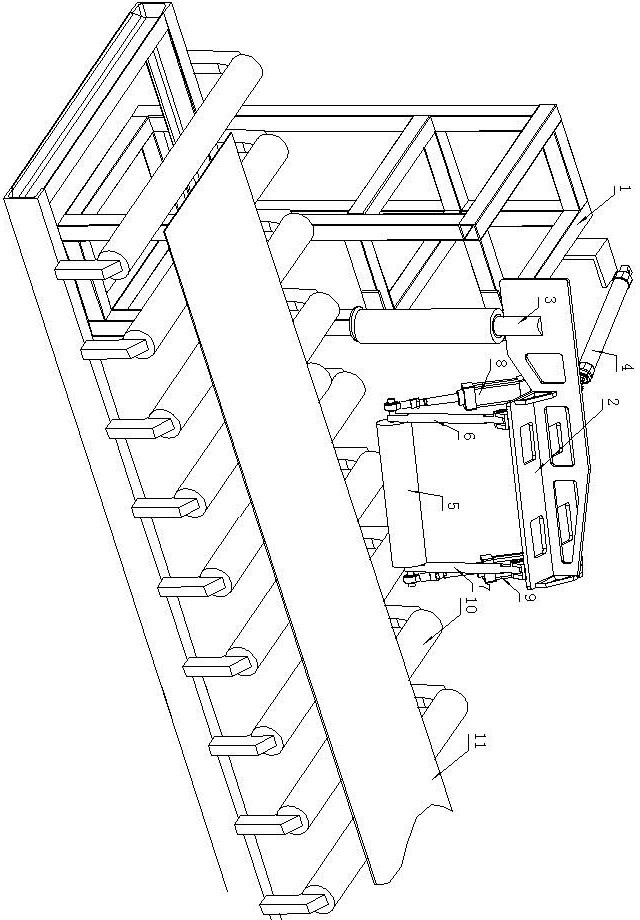

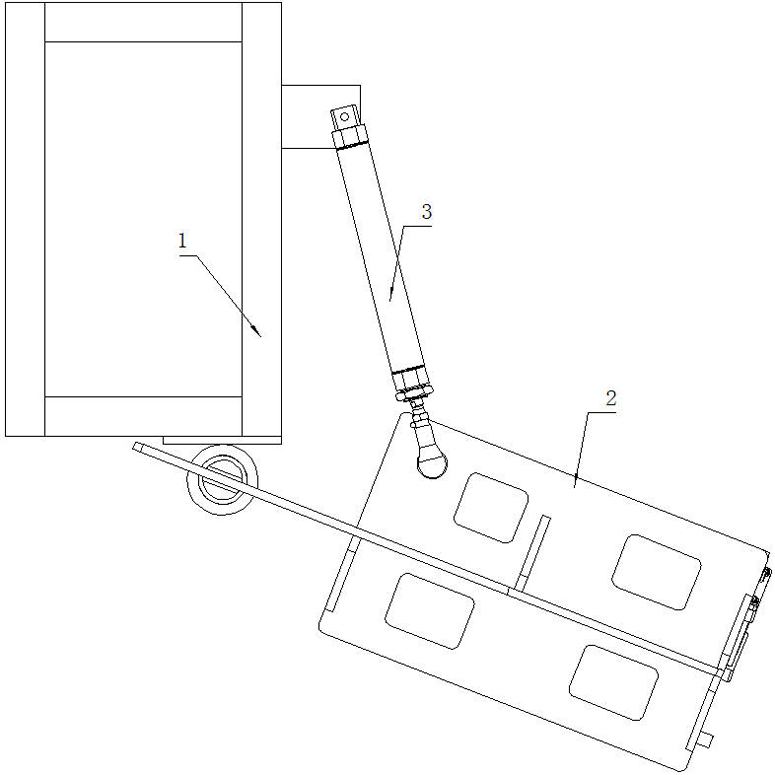

[0013] In the invention as shown in the figure, a support 1 is provided on one side of the drum transmission line. There is a bearing on the inside of the top of the support 1. There is a rotating shaft 3 in the bearing. There is a groove on the top of the rotating shaft 3. A vertical plate is embedded in the groove, and the vertical plate is another The bottom of one end is fixedly connected to the fixed frame 2 , the top of the bracket 1 is pivotally connected to the horizontal cylinder 4 , and the other end of the horizontal cylinder 4 is pivotally connected to the back of the fixed frame 2 .

[0014] Respectively pivotally connect a connecting rod on both sides of the front of the bottom of the fixed frame 2, which are respectively the left connecting rod 6 and the right connecting rod 7. The ends of the ends are respectively pivo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com