Long and thin double-engine air inlet channel structure and assembling method

An air inlet and flange technology, which is applied in the field of slender dual-engine air inlet structure and assembly, can solve the problems of many frames in the air inlet assembly area, difficulty in demoulding the forming tool, and limited connection channels, etc. The effect of good surface quality, easy accurate positioning and assembly, and low process risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

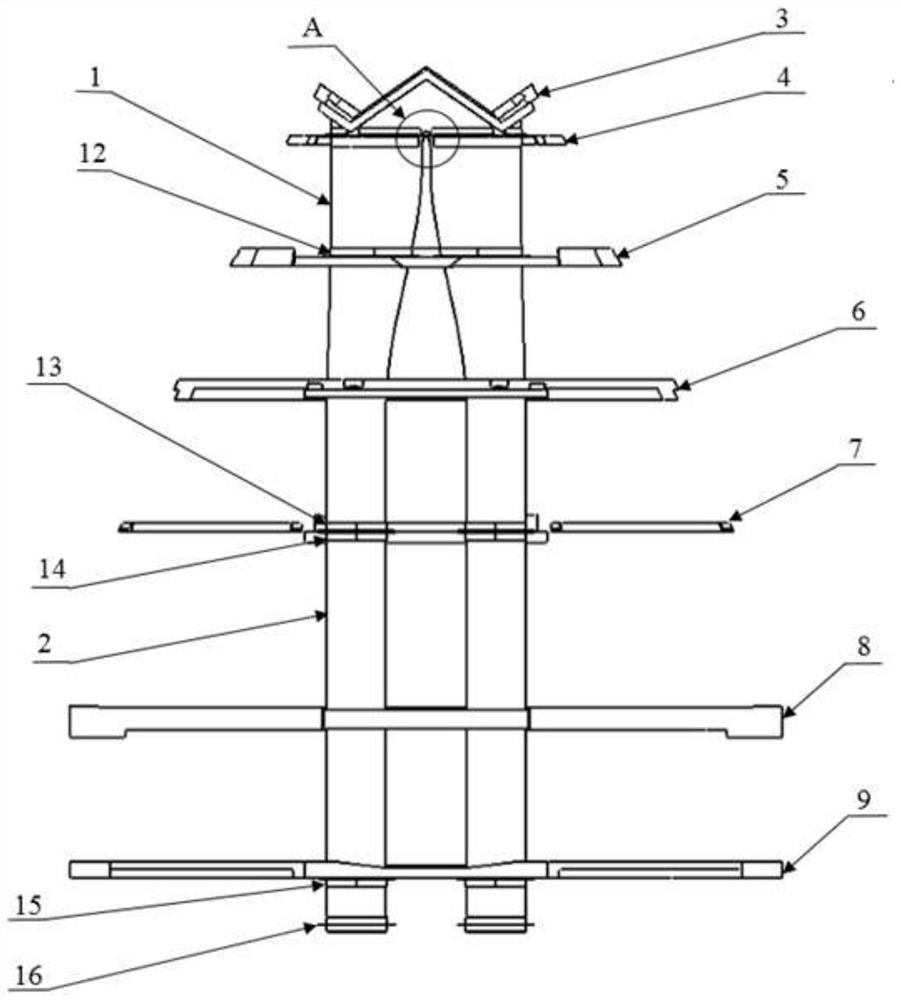

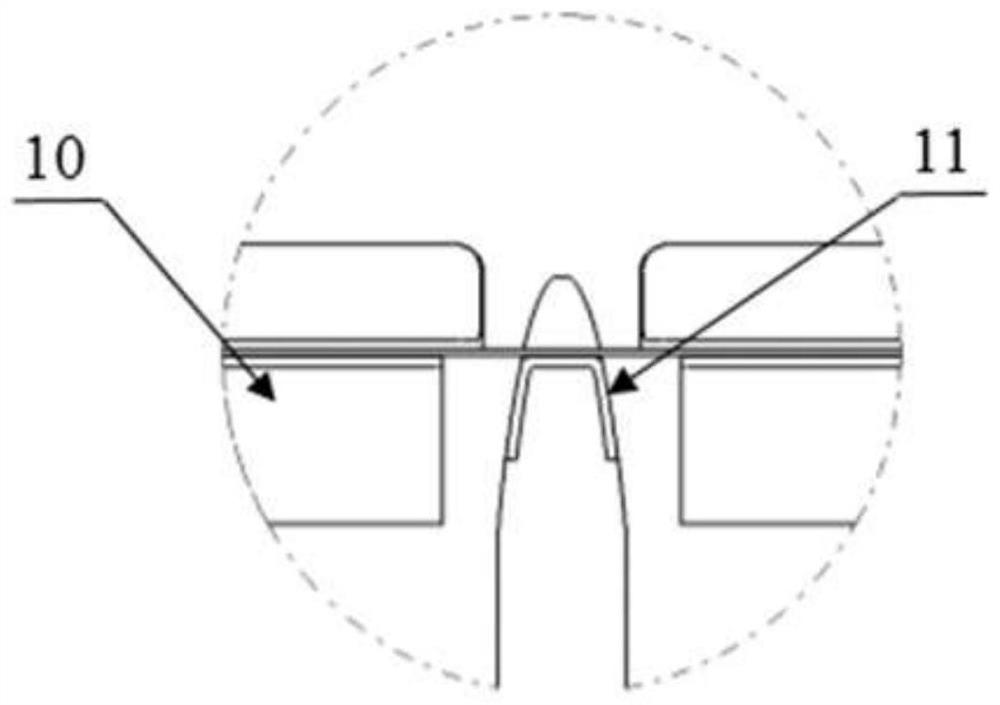

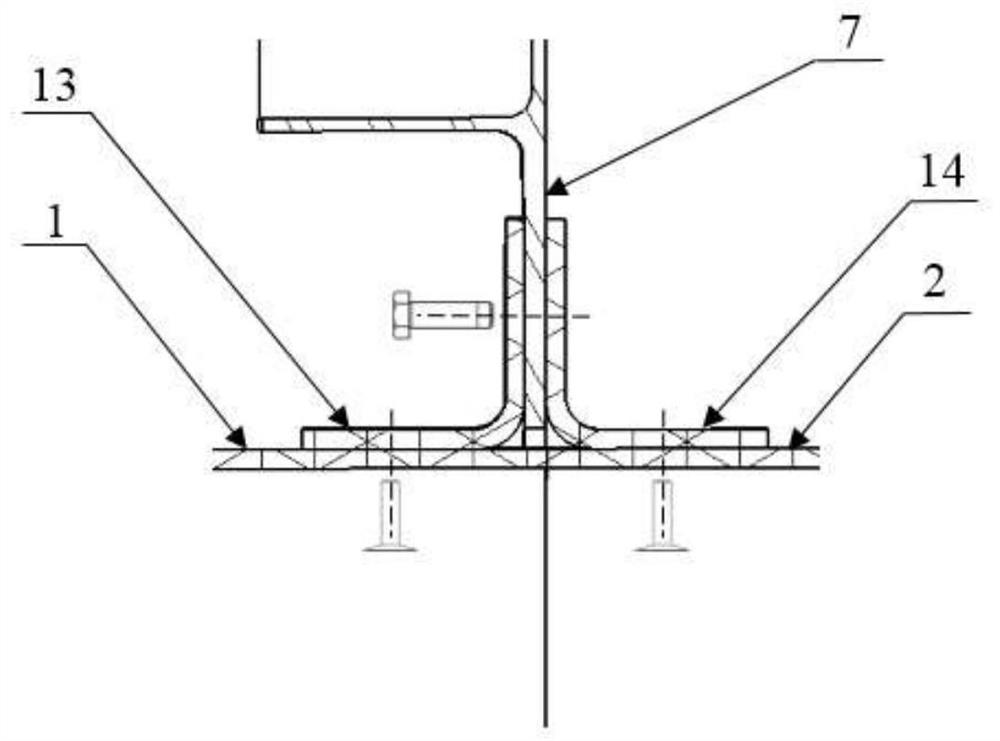

[0050] A dual engine inlet structure, such as Figure 1-3 As shown, it includes two air inlets arranged side by side, and the two air inlets have the same structure; they are arranged symmetrically in the frame structure. Among them, the total length of each air inlet is 2285mm, and the air inlet is irregularly flat and gradually transitions to a circle. Each air inlet includes a front section 1 of the air inlet and a rear section 2 of the air inlet that are detachably connected; From the front section 1 of the air intake duct to the rear section 2 of the air intake duct, a plurality of assembly frames for fixing to the frame are sequentially arranged at intervals. The first half of the inlet is S-shaped, and the second half is straight. The cross-section width of the air inlet is 85-290mm, and the diameter of the straight section of the air inlet is 166mm.

[0051] Specifically, the assembly frame includes a first fixed frame 4, a second fixed frame 5, a third fixed frame 6...

Embodiment 2

[0060] A kind of assembly method of double-engine inlet, such as Figure 4-9 As shown, the double-engine intake port structure comprising embodiment 1 specifically includes the following steps:

[0061] Step 1, respectively fixing the flange, the first connecting ring and the second connecting ring on corresponding positions of the air inlet;

[0062] Step 2. Position and assemble the lower half frame of the second fixed frame, the third fixed frame, the fourth fixed frame, the lower half frame of the fifth fixed frame and the sixth fixed frame in the body skeleton; The fixed frame, the upper half frame of the second fixed frame and the upper half frame of the fifth fixed frame are pre-assembled, and disassembled after the pre-assembly is completed;

[0063] Step 3. Put the front section of the air inlet into the body frame from front to back, and put the rear section of the air inlet into the body frame from back to front;

[0064] Step 4: Reinstall the lip in step 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com