Device and method for humidifying soil body by combining vacuum pump suction with steam

A vacuum pump and steam technology, which is applied in the direction of measuring devices, soil testing, and sample preparation for testing, can solve the problems of difficult control of humidification range, inability to humidify in batches, small humidification range, etc., and achieve faster transportation and Humidification rate, overcoming the effect of long humidification time, simple installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

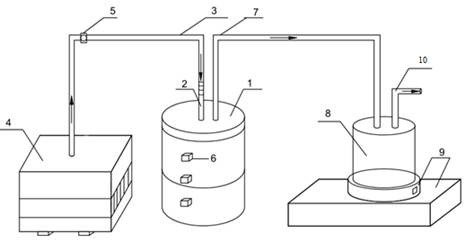

[0063] The rated evaporation capacity of the steam generator is 80kg / h, and the rated steam temperature is 171°C.

[0064] The measuring range of the pressure regulating valve is 0.7MPa, and the precision is 10kPa.

[0065] The humidification chamber adopts a model steel barrel with a cover of 200 cm in diameter and 150 cm in height.

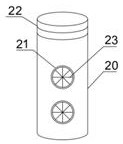

[0066] In order to better analyze and compare the humidification effect of soil at different depths, three temperature and humidity sensors are installed on the model steel drum with a height of 40cm.

[0067]The range of the temperature and humidity sensor is 0-100% (m 3 / m 3 ), the working temperature range is -30℃~70℃, the resolution is 0.01% (m 3 / m 3 ).

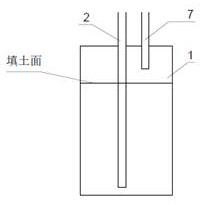

[0068] The cover of the model steel barrel is respectively provided with through holes through which the humidification pipe and the exhaust pipe can pass, and is sealed with a sealing member.

[0069] The humidification tube is a copper tube with one end closed and the other end pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com