Thrust bearing structure of small reactor shield pump

A technology for thrust bearings and canned pumps, which is applied to pumps, pump components, non-variable pumps, etc., can solve the problems of high starting performance requirements of canned pumps, low efficiency of canned pumps, and large friction losses, so as to reduce stirring losses, The effect of extended running time and small axial shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

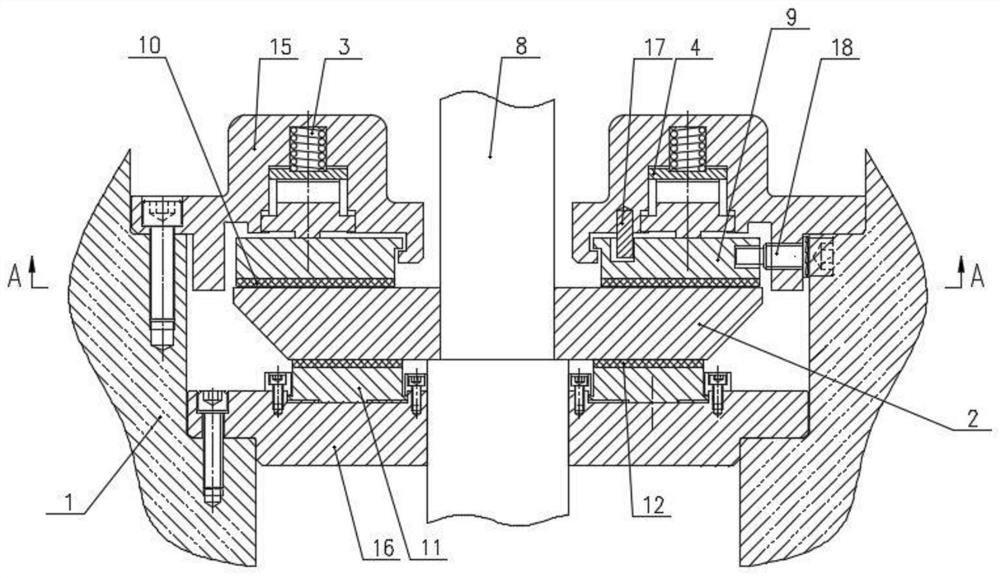

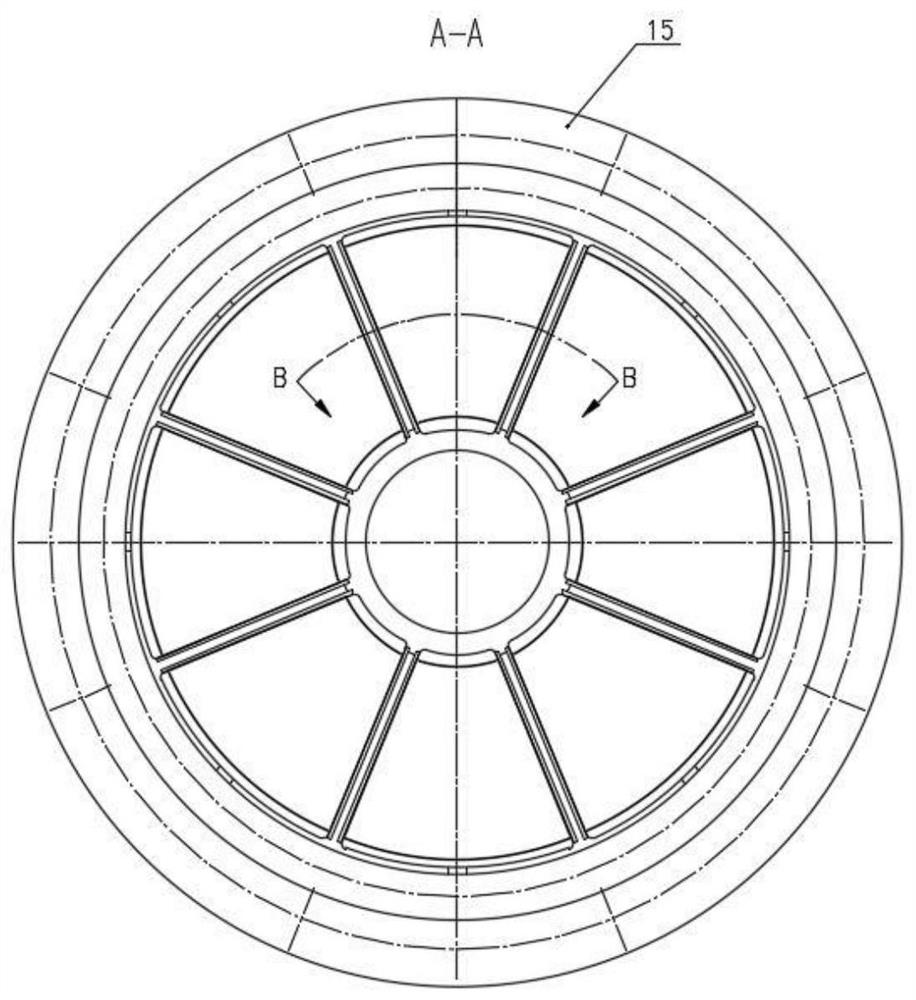

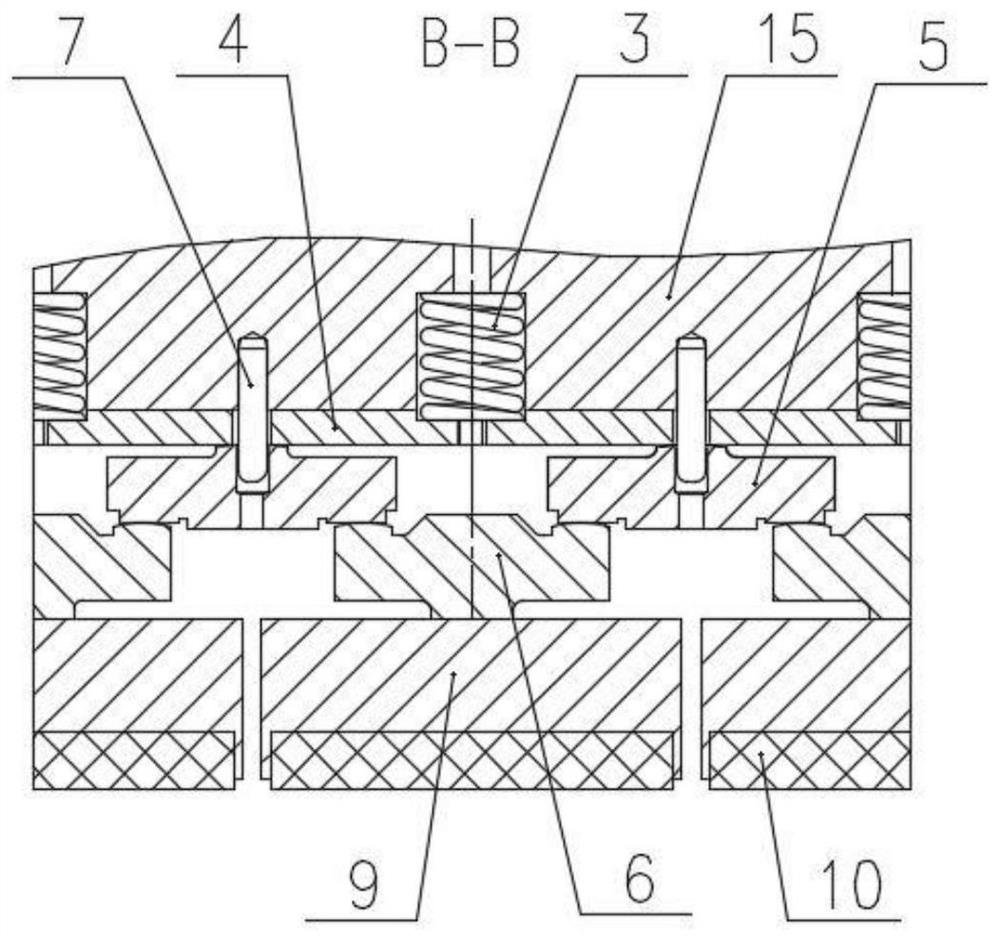

[0017] Such as figure 1 As shown, the upper thrust bearing seat 15 and the lower thrust bearing seat 16 are fastened on the machine base 1 by bolts through their respective protruding outer edges, as image 3 As shown, a compression spring 3 is installed in the upper thrust bearing seat 15, and a spring plate 4 is installed at the lower part of the compression spring 3. The spring plate 4 is a whole ring structure. The block limit pin 7 is limited, and the adjacent upper balance weight 5 and the lower balance weight 6 cooperate through the cylindrical surface on the lower balance weight 6. The upper balance weight 5 and the lower balance weight 6 are evenly distributed along the spring plate 4 circumferential direction, and the upper thrust tile The tile base 9 is in contact with the lower balance weight 6, and the upper thrust tile base 9 is fixed radially by the limit pin 17 on the upper thrust bearing seat 15, and the upper thrust tile base 9 is axially fixed by figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com