Cold-resistant school uniform fabric and preparation method thereof

A technology for fabrics and school uniforms, applied to clothing, clothing, fabric surface trimming, etc., can solve the problems of clothing deformation, inability to actively heat up, students getting cold and sick, etc., to prevent deformation, increase heat preservation effect, and increase the effect of cold protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

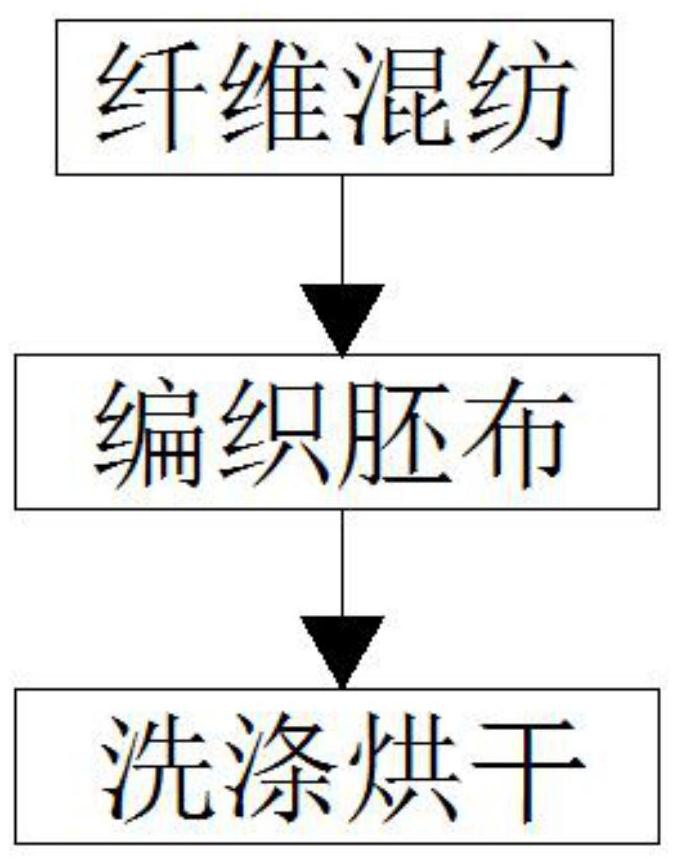

[0026] Further, a kind of warm school uniform fabric, using said warm school uniform fabric, the steps of the preparation method of a kind of warm school uniform fabric are as follows:

[0027] Step 1: Blending aramid fibers, wool fibers, shape memory fibers, heating fibers, volcanic rock fibers, and Coolmax moisture-absorbing and sweat-wicking fibers using a blending machine;

[0028] Step 2: Then the weft yarn is inserted through the weft insertion machine, the warp and weft yarns are interwoven to form a veil layer, and the gray cloth is woven by a weaving machine;

[0029] Step 3: After the gray cloth is bleached with hydrogen peroxide, washed and dried, then soaked in the soaking solution, and then steamed to obtain a base cloth;

[0030] Further, the time of immersion in the immersion liquid in the step 3 is 10-20min.

[0031] Further, the temperature for washing, drying and setting in the third step is 120°C-130°C.

Embodiment 1

[0033] The cold-proof school uniform fabric includes the following raw materials and their weight fractions: 10 parts of aramid fiber, 10 parts of wool fiber, 5 parts of shape memory fiber, 3 parts of heating fiber, 3 parts of volcanic rock fiber, and 10 parts of Coolmax moisture-wicking fiber.

[0034] The preparation steps are as follows:

[0035] a. taking the above-mentioned raw materials according to parts by weight;

[0036] Step 1: Blending aramid fibers, wool fibers, shape memory fibers, heating fibers, volcanic rock fibers, and Coolmax moisture-absorbing and sweat-wicking fibers using a blending machine;

[0037] Step 2: Then the weft yarn is inserted through the weft insertion machine, the warp and weft yarns are interwoven to form a veil layer, and the gray cloth is woven by a weaving machine;

[0038] Step 3: After the gray cloth is bleached with hydrogen peroxide, washed and dried, then soaked in the soaking solution, and then steamed to obtain a base cloth;

Embodiment 2

[0040] The cold-proof school uniform fabric includes the following raw materials and their weight fractions: 15 parts of aramid fiber, 13 parts of wool fiber, 6 parts of shape memory fiber, 5 parts of heating fiber, 4 parts of volcanic rock fiber, and 13 parts of Coolmax moisture-wicking fiber.

[0041] The preparation steps are as follows:

[0042] a. taking the above-mentioned raw materials according to parts by weight;

[0043] Step 1: Blending aramid fibers, wool fibers, shape memory fibers, heating fibers, volcanic rock fibers, and Coolmax moisture-absorbing and sweat-wicking fibers using a blending machine;

[0044] Step 2: Then the weft yarn is inserted through the weft insertion machine, the warp and weft yarns are interwoven to form a veil layer, and the gray cloth is woven by a weaving machine;

[0045] Step 3: After the gray cloth is bleached with hydrogen peroxide, washed and dried, then soaked in the soaking solution, and then steamed to obtain a base cloth;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com