High-dispersion viscosity-reducing mortar

A high-dispersion and viscosity-reducing technology, applied in the field of mortar, can solve the problems of poor viscosity-reducing performance, poor dispersibility, and easy agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

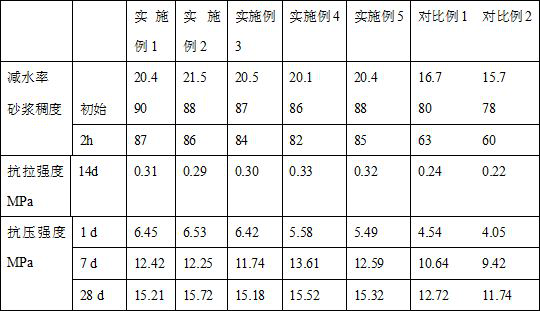

Examples

Embodiment 1

[0023] Example 1

[0024] A high-dispersion viscosity-reducing mortar, characterized in that: the mortar is composed of powder and liquid, and the powder has the following ingredients in parts by mass: 30 parts of Portland cement, 55 parts of sand, 15 parts of silica fume powder , 10 parts of slag, the following ingredients of the liquid material in parts by mass: 2 parts of hydroxypropyl methylcellulose ether, 6 parts of styrene-butadiene emulsion, 9 parts of dispersed viscosity-reducing water reducer, 40 parts of water,

[0025] The preparation method of the highly dispersed viscosity-reducing mortar comprises the following steps:

[0026] Weigh the liquid materials hydroxypropyl methylcellulose ether, styrene-butadiene emulsion, dispersed viscosity-reducing water reducer, and water according to the proportion and mix them evenly for later use;

[0027] Weigh the powdered Portland cement, sand, silica fume powder and slag according to the proportion, add them to the mortar ...

Embodiment 2

[0033] A high-dispersion viscosity-reducing mortar, characterized in that: the mortar is composed of powder and liquid, and the powder has the following ingredients in parts by mass: 28 parts of Portland cement, 54 parts of sand, and 10 parts of silica fume powder , 18 parts of slag, the following ingredients of the liquid material in terms of parts by mass: 3 parts of hydroxypropyl methylcellulose ether, 5 parts of styrene-butadiene emulsion, 8 parts of dispersed viscosity-reducing superplasticizer, 35 parts of water,

[0034] The preparation method of the highly dispersed viscosity-reducing mortar comprises the following steps:

[0035] Weigh the liquid materials hydroxypropyl methylcellulose ether, styrene-butadiene emulsion, dispersed viscosity-reducing water reducer, and water according to the proportion and mix them evenly for later use;

[0036] Weigh the powdered Portland cement, sand, silica fume powder and slag according to the proportion, add them to the mortar mixe...

Embodiment 3

[0042] A high-dispersion viscosity-reducing mortar, characterized in that: the mortar is composed of powder and liquid, and the powder has the following ingredients in parts by mass: 20 parts of Portland cement, 60 parts of sand, 20 parts of silica fume powder , 12 parts of slag, the following ingredients of the liquid material in parts by mass: 1 part of hydroxypropyl methylcellulose ether, 6 parts of styrene-butadiene emulsion, 8 parts of dispersed viscosity-reducing water reducer, 34 parts of water,

[0043] The preparation method of the highly dispersed viscosity-reducing mortar comprises the following steps:

[0044] Weigh the liquid materials hydroxypropyl methylcellulose ether, styrene-butadiene emulsion, dispersed viscosity-reducing water reducer, and water according to the proportion and mix them evenly for later use;

[0045] Weigh the powdered Portland cement, sand, silica fume powder and slag according to the proportion, add them to the mortar mixer and mix them ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com