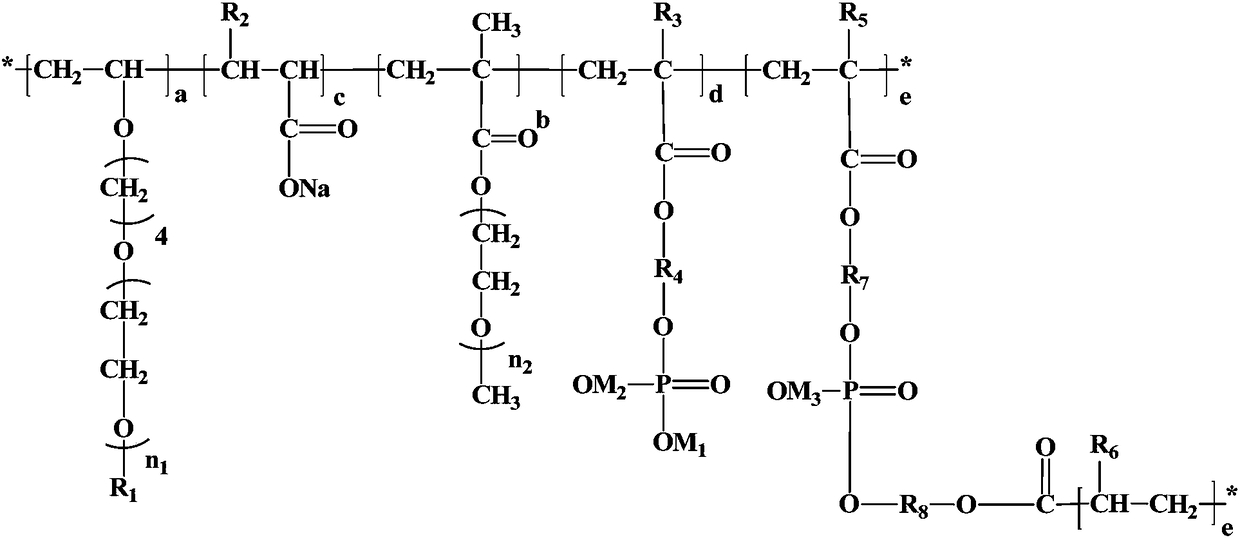

A cross-linked low-sensitivity ester ether copolymerization polycarboxylate water reducer and its preparation method

A sensitive ester and cross-linking technology, which is applied in the field of building materials, can solve the problems of water reducing agent dosage sensitivity, dosage sensitivity has not been improved, etc., achieve good anti-intercalation effect, excellent low sensitivity performance, improve secretion water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

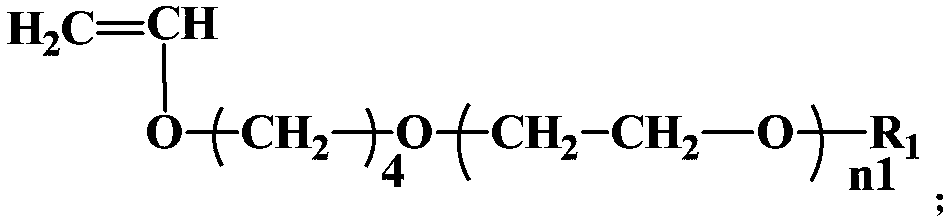

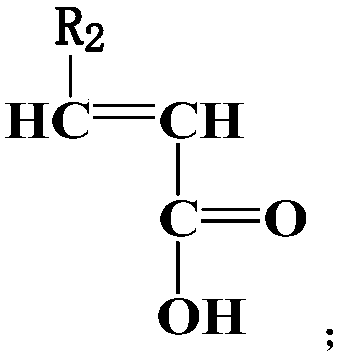

Method used

Image

Examples

Embodiment 1

[0044] (1) 160 g of VPEG-type monomers with a number average molecular weight of 2000 were dissolved in 175 g of deionized water, and the temperature was adjusted to 15° C. to obtain the first solution;

[0045] (2) 25 g of acrylic acid and 1.4 g of mercaptopropionic acid were dissolved in 20 g of deionized water, and then 9.5 g of 30% potassium hydroxide solution was added for partial neutralization to obtain a second solution;

[0046] (3) 0.55g sodium formaldehyde sulfoxylate is dissolved in 30g deionized water to obtain the third solution;

[0047] (4) the MPEG type monomer that the number average molecular weight is 2400 is dissolved in deionized water to obtain 45g of the fourth solution with a concentration of 90%. The methacrylic acid (MAA) and polyethylene glycol in the above MPEG type monomer The acid-alcohol ratio of alcohol monomethyl ether (MPEG) is 2.5;

[0048] (5) Add 21g of the second solution dropwise to the first solution, and keep the temperature at 15°C; ...

Embodiment 2

[0052] (1) 140 g of VPEG-type monomers with a number average molecular weight of 2000 were dissolved in 174 g of deionized water, and the temperature was adjusted to 15° C. to obtain the first solution;

[0053] (2) 24 g of acrylic acid and 1.4 g of thioglycolic acid were dissolved in 20 g of deionized water, and then 9 g of 30% sodium hydroxide solution was added for partial neutralization to obtain a second solution;

[0054] (3) 0.6gFF6 was dissolved in 30g deionized water to obtain the third solution;

[0055] (4) Dissolving the MPEG type monomer with the number average molecular weight of 2000 in deionized water to obtain 60 g of the fourth solution with a concentration of 90%, the methacrylic acid (MAA) and polyethylene glycol in the above MPEG type monomer The acid-alcohol ratio of alcohol monomethyl ether (MPEG) is 3.5;

[0056] (5) Add 20 g of the second solution dropwise to the first solution, and keep the temperature at 15°C;

[0057] (6) 3 g of 2-methacryloxyprop...

Embodiment 3

[0060] (1) Dissolving 100 g of a VPEG-type monomer with a number average molecular weight of 3000 in 170 g of deionized water, and adjusting its temperature to 14° C. to obtain the first solution;

[0061] (2) 20 g of acrylic acid and 1.2 g of mercaptoethanol were dissolved in 20 g of deionized water, and then 8 g of 30% sodium hydroxide solution was added for partial neutralization to obtain a second solution;

[0062] (3) 0.5g sodium hypophosphite is dissolved in 30g deionized water to obtain the third solution;

[0063] (4) Dissolving the MPEG type monomer with the number average molecular weight of 2000 in deionized water to obtain 100 g of the fourth solution with a concentration of 90%, the methacrylic acid (MAA) and polyethylene glycol in the above MPEG type monomer The acid-alcohol ratio of alcohol monomethyl ether (MPEG) is 2.5;

[0064] (5) Add 15 g of the second solution dropwise to the first solution, and keep the temperature at 14°C;

[0065] (6) Add 2.5 g of ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com