Solid-liquid separation process for fluorescent whitening slurry wastewater

A technology for solid-liquid separation and whitening slurry, which is applied in the field of solid-liquid separation of fluorescent whitening slurry wastewater, can solve the problems of difficult treatment of emulsified oil wastewater, effective treatment methods and high treatment costs, and achieves reduction in post-treatment. Burden, simplified post-processing, reduced COD effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A solid-liquid separation process for fluorescent whitening slurry wastewater, the operation steps are:

[0033] First, pump 800g of fluorescent whitening slurry wastewater into the heating reactor and heat to 70°C. After heating and stirring for 1h, add hydrochloric acid to adjust the pH to pH8, add 1.2g of demulsifier, then add 0.05g of coagulant, and heat to 80°C. ℃, heated and stirred for 30 minutes, and then placed in a centrifuge for solid / liquid separation after treatment. The clarified liquid is filtered through sand and then filtered through activated carbon adsorption.

[0034] The mass fraction of the hydrochloric acid is 10%.

[0035] The added demulsifier is compounded by PAC and PAM, and its synthetic ratio is 30:1.

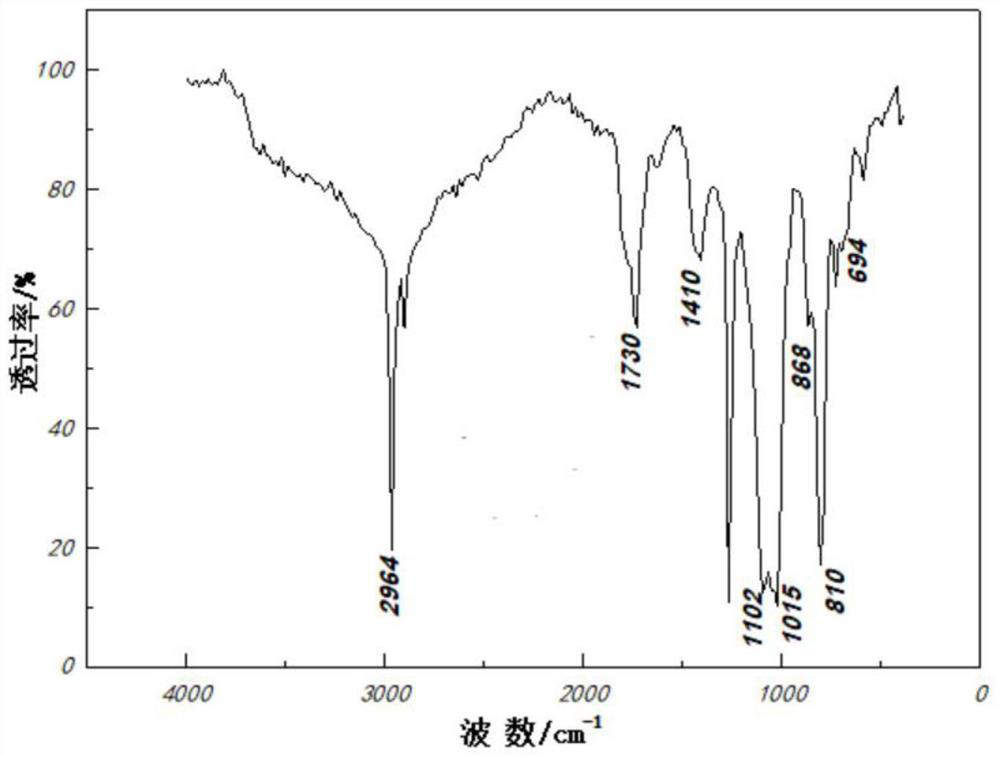

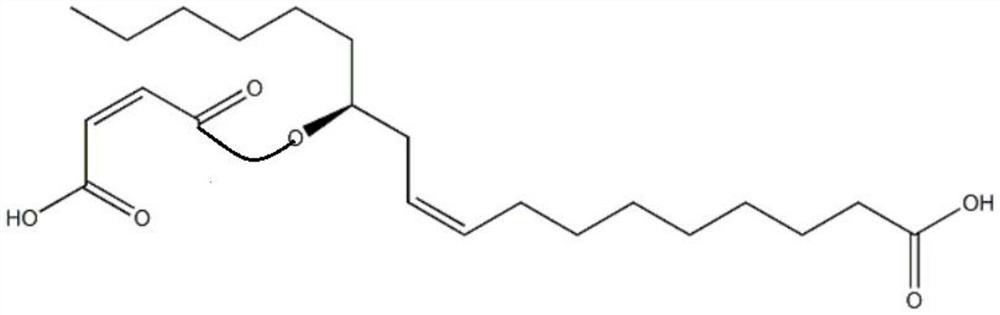

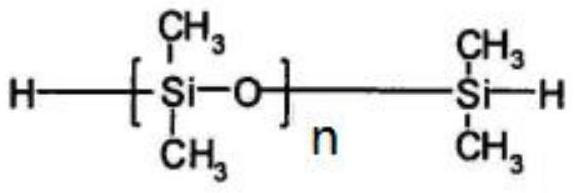

[0036] The preparation method of described coagulation aid is:

[0037] 17g of diallyldimethylammonium chloride, 2.2g of castor oil maleate, and 0.02g of aluminum acrylate are added to the reaction kettle, and high-purity nitrogen protecti...

Embodiment 2

[0040] A solid-liquid separation process for fluorescent whitening slurry wastewater, the operation steps are:

[0041] First, pump 800g of fluorescent whitening slurry wastewater into the heating reactor and heat to 75°C. After heating and stirring for 1 hour, add hydrochloric acid to adjust the pH to pH8, add 2g of demulsifier, then add 0.15g of coagulant aid, and heat to 80°C , heated and stirred for 30 minutes, and then placed in a centrifuge for solid / liquid separation after treatment. The clarified liquid is filtered through sand and then filtered through activated carbon adsorption.

[0042] The mass fraction of the hydrochloric acid is 12%.

[0043] The added demulsifier is compounded by PAC and PAM, and its synthetic ratio is 20:1.

[0044] The preparation method of described coagulation aid is:

[0045] 20g of diallyldimethylammonium chloride, 3g of castor oil maleate, and 0.1g of aluminum acrylate are added to the reaction kettle, and high-purity nitrogen protect...

Embodiment 3

[0049] A solid-liquid separation process for fluorescent whitening slurry wastewater, the operation steps are:

[0050] First, pump 800g of fluorescent whitening slurry wastewater into the heating reactor and heat to 75°C. After heating and stirring for 1h, add hydrochloric acid to adjust the pH to pH8, add 2.4g of demulsifier, then add 0.2g of coagulant, and heat to 80 ℃, heated and stirred for 30 minutes, and then placed in a centrifuge for solid / liquid separation after treatment. The clarified liquid is filtered through sand and then filtered through activated carbon adsorption.

[0051] The mass fraction of the hydrochloric acid is 14%.

[0052] The added demulsifier is compounded by PAC and PAM, and its synthetic ratio is 15:1.

[0053] The preparation method of described coagulation aid is:

[0054] 22g of diallyldimethylammonium chloride, 3.5g of castor oil maleate, and 0.2g of aluminum acrylate are added to the reaction kettle, and high-purity nitrogen protection is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com