Novel steam-water separation device

A technology of steam-water separation device and separation device, which is applied in the direction of combination device, separation method, and dispersed particle separation, etc. It can solve the problems that internal parts are easily corroded by water vapor, reduce the service life of the device, increase the difficulty of maintenance, etc., and achieve good results. Sealing, reducing rust, reducing the effect of scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

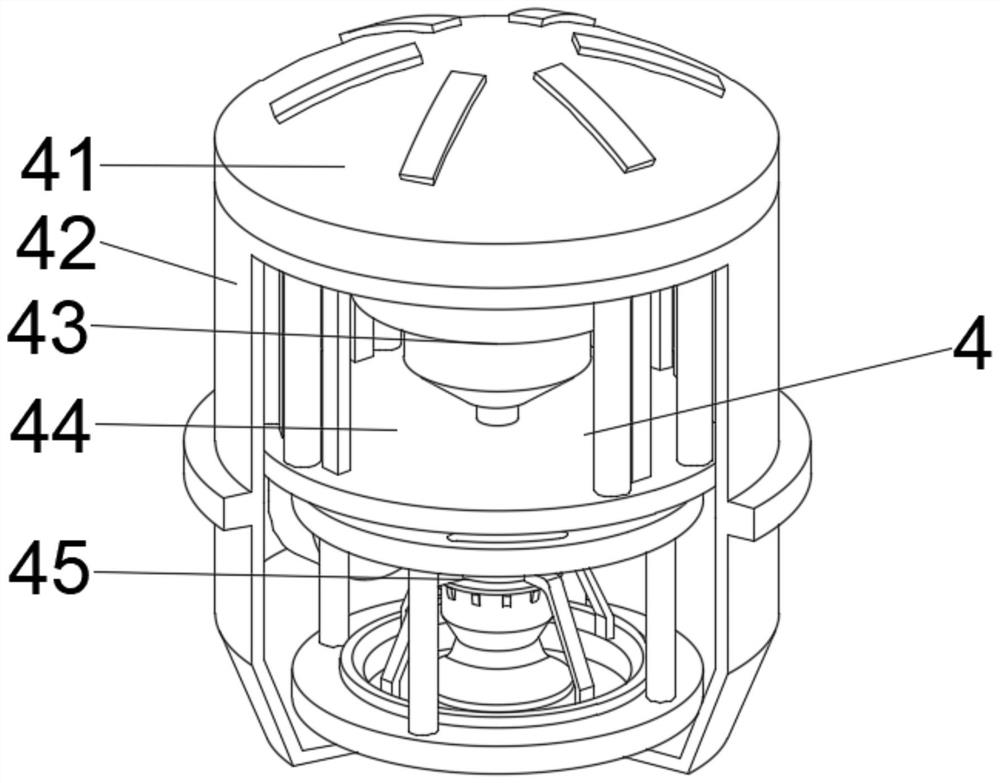

[0040] see Figure 1-6 , the present invention provides a technical solution: a new type of steam-water separation device, including a water storage base 2, the middle part of the outer wall on the right side of the water storage base 2 is connected with an air outlet pipe 1, and the top left side of the water storage base 2 is connected with a drain tube 5 , the middle part of the left outer wall of the hydrophobic cylinder 5 is connected with an air intake pipe 6, the top right middle part of the water storage base 2 is fixedly connected with a fastening plate 3, the top of the fastening plate 3 is provided with a separation device 4, and the bottom of the separation device 4 runs through The fastening plate 3 extends to the inside of the fastening plate 3 .

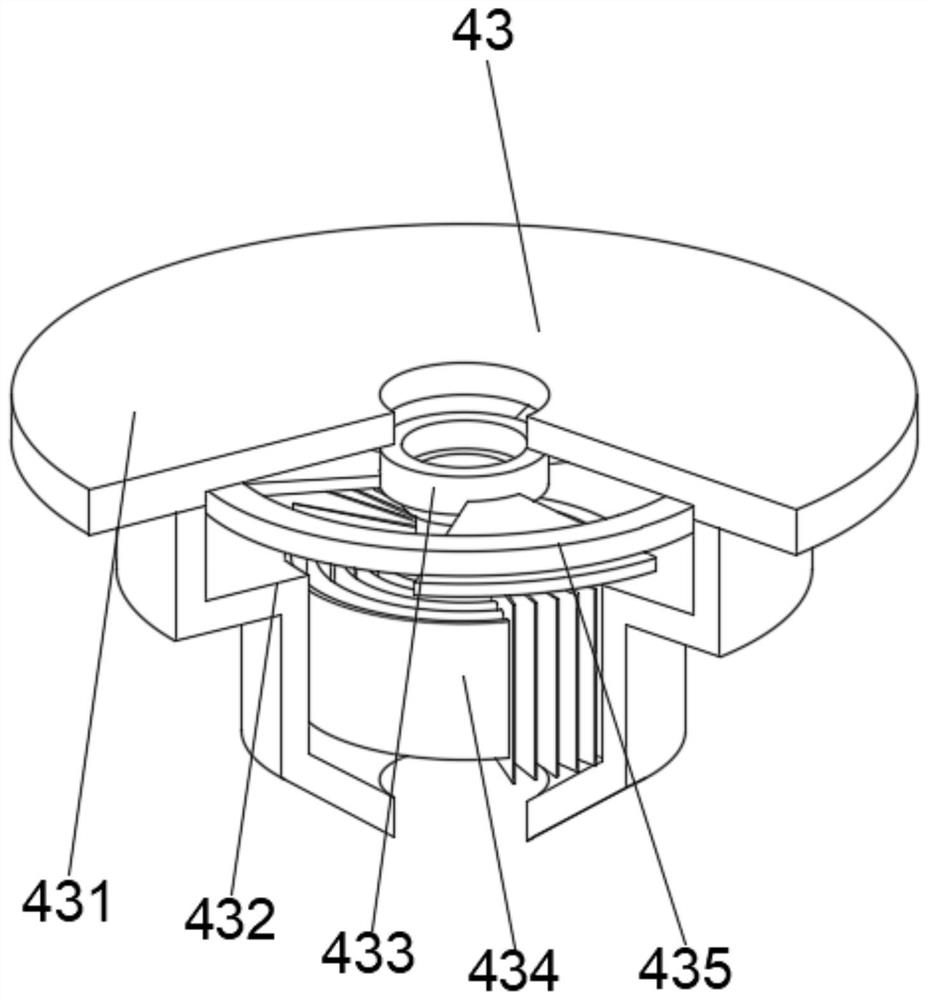

[0041] Wherein, the separation device 4 includes a separation tank 42, the top of the separation tank 42 is provided with a sealing top cover 41, the middle position of the inner cavity bottom of the separation tank 42...

Embodiment 2

[0047] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method of using a new type of steam-water separation device, step 1: install the device, and insert the hydrophobic cylinder 5 into the water storage base 2, use the tight The clamping connection of the fixing plate 3 connects the separation device 4 with the water storage base, and fills the inside of the water storage base 2 with water;

[0048] Step 2: Connect the separation tank 42 with the external circulation pipeline, connect the solid bracket 44 with the separation mechanism 43, and communicate with the flow guide mechanism 45 through the separation mechanism 43 through the communication pipe to realize internal quantitative transfer;

[0049] Step 3: Connect the multiple separation body 434 to the power part through the rotating frame 433, and use the limit ring 435 to support the rotating frame 433, so as to achieve the flow chamber where the internal rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com