Material filling type hollow fiber bragg grating and preparation method thereof

A fiber grating, filled-type technology, applied in the directions of cladding fiber, optical waveguide light guide, light guide, etc., can solve the problems of complicated manufacturing process, unfavorable large-area promotion, reduced mechanical strength and service life of optical fiber, etc. Simple, low insertion loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

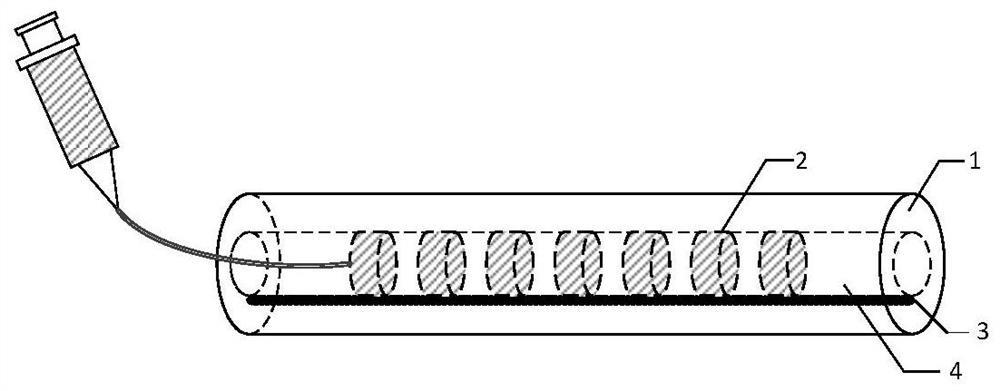

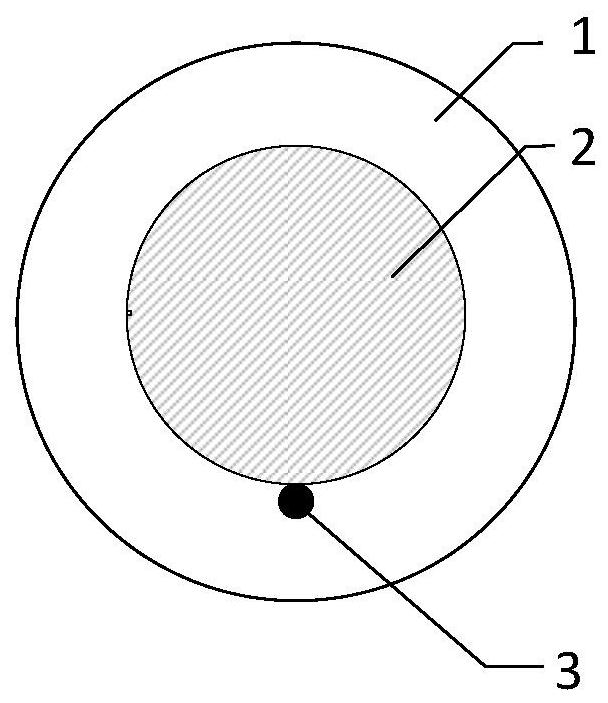

[0032] like figure 1 As shown, a schematic diagram of the preparation of a material-filled hollow fiber grating designed by the present invention includes a four-layer structure: an optical fiber annular cladding, an air hole cladding, an optical fiber grating, and an optical fiber core. Preparation includes the following steps:

[0033] Step 1.1: The capillary is heated and pulled to form a tapered tip with a diameter of about 2 microns. Align the capillary filled with the liquid functional material with the air hole cladding of the capillary fiber to be written, and pressurize the syringe to fill the central air hole of the capillary fiber with the liquid functional material;

[0034] Step 1.2: melt and taper one end of the capillary fiber to be written, and prepare a semi-closed cavity at one end of the fiber;

[0035] Step 1.3: Fix the semi-closed cavity prepared in the previous step in the optical fiber fusion splicer, and then fix the syringe on the syringe pump. By ad...

Embodiment 2

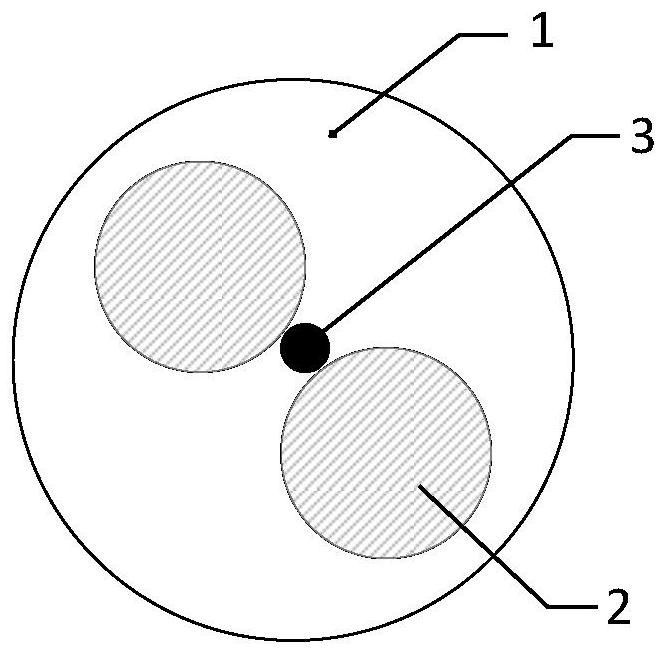

[0038] As shown in Figure 2(b), a schematic diagram of the preparation of a double-hole material-filled hollow fiber grating designed by the present invention, the air holes are symmetrically distributed on both sides of the fiber core, and each air hole is responsible for a grating array. The specific preparation scheme is as follows :

[0039] Step 2.1: The capillary is heated and pulled to form a tapered tip with a diameter of about 2 microns. Align the capillary filled with the liquid functional material with the air hole cladding of the capillary fiber to be written, and pressurize the syringe to make the liquid functional material fill the central air hole (4) of the capillary fiber

[0040] Step 2.2: melt and taper one end of the capillary fiber to be written, and prepare a semi-closed cavity at one end of the fiber;

[0041] Step 2.3: Fix the semi-closed cavity prepared in the previous step in the optical fiber fusion splicer, and then fix the syringe on the syringe p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com