A fluidized bed dryer based on graphene far-infrared heating and drying method thereof

A fluidized bed dryer and far-infrared technology, applied in the direction of heating to dry solid materials, dryers, drying solid materials, etc., can solve the problems that high-temperature heating elements cannot be in contact with materials, there is a risk of open flames, and the amount of materials is small , to achieve the effect of fast speed, reducing waist burst rate and reducing oil oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

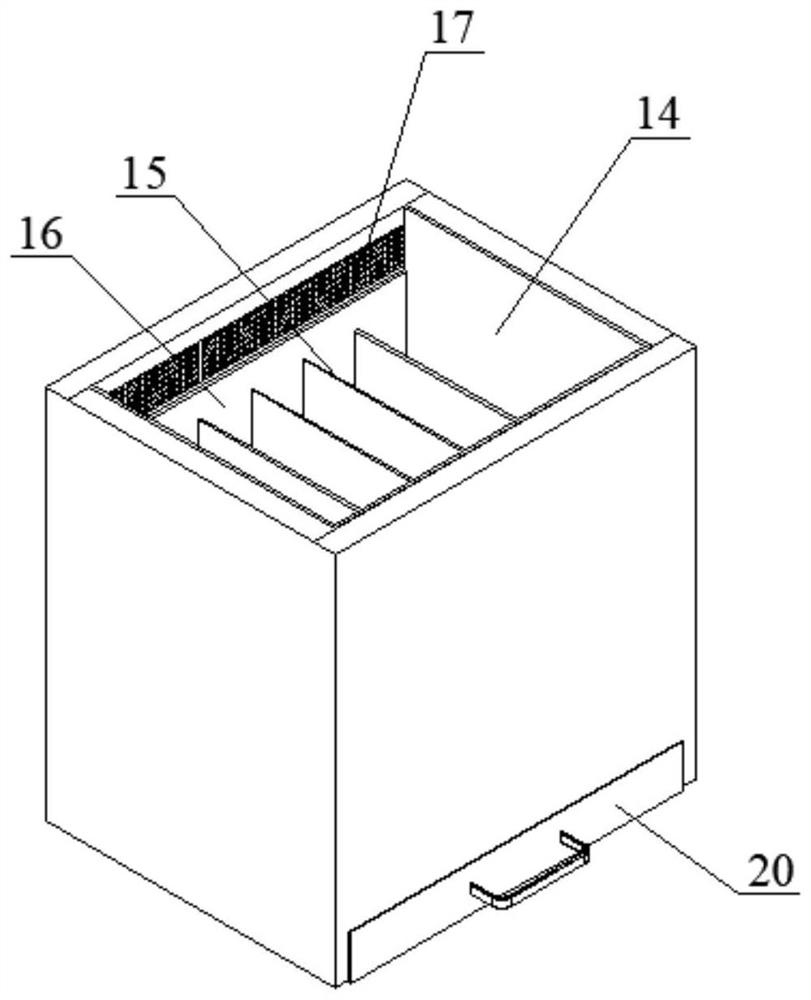

[0028] like Figure 1 to Figure 3 As shown, a fluidized bed dryer based on graphene far-infrared heating of the present invention includes a controller 2 and a drier 1, an air expansion pipe 3 is arranged below the drier 1 to communicate with the bottom air supply channel 4, and the bottom air supply channel The other end of 4 is connected to the air outlet of the centrifugal fan 7, and a return air duct assembly is provided at the adjacent position of the air inlet of the centrifugal fan 7, and is connected to the air outlet above the dryer 1 through the return air duct assembly, and the top of the dryer 1 is also Be provided with feeder 13; Dryer 1 comprises main body drying chamber, and the outer wall of main body drying chamber is provided with insulating layer 18, and the inwall of main body dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com