Filling structure for preventing instability of filling body and mining method applying filling structure

A mining method and backfill technology, which are applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of easily damaged backfill false roofs, etc., and achieve the effects of simplifying backfilling procedures, high efficiency, and saving backfill costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

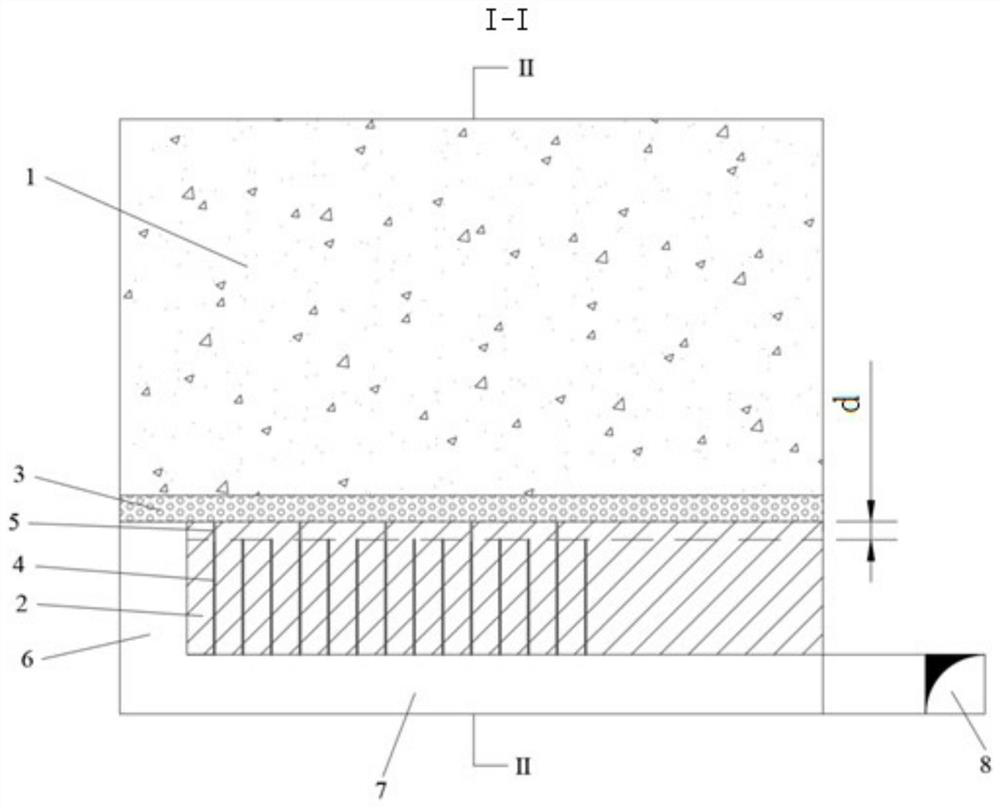

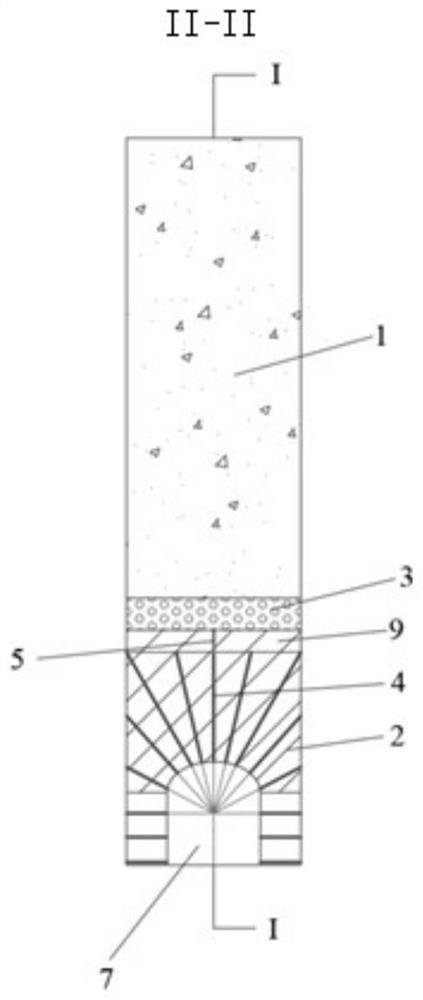

[0035] see figure 1 and figure 2 , the stope in the illustration is a specific embodiment of the filling structure that prevents the filling body from destabilizing according to the present invention. After the upper part of the stope is excavated, the upper goaf is filled to form a filling body 1, and the bottom remains Pillar ore body 2, after the upper stope excavation is completed, the bottom pillar ore body 2 needs to be mined by blasting. In this embodiment, in the process of filling the goaf, a filling structure is provided to prevent the filling body from being unstable when the bottom pillar ore body is blasted.

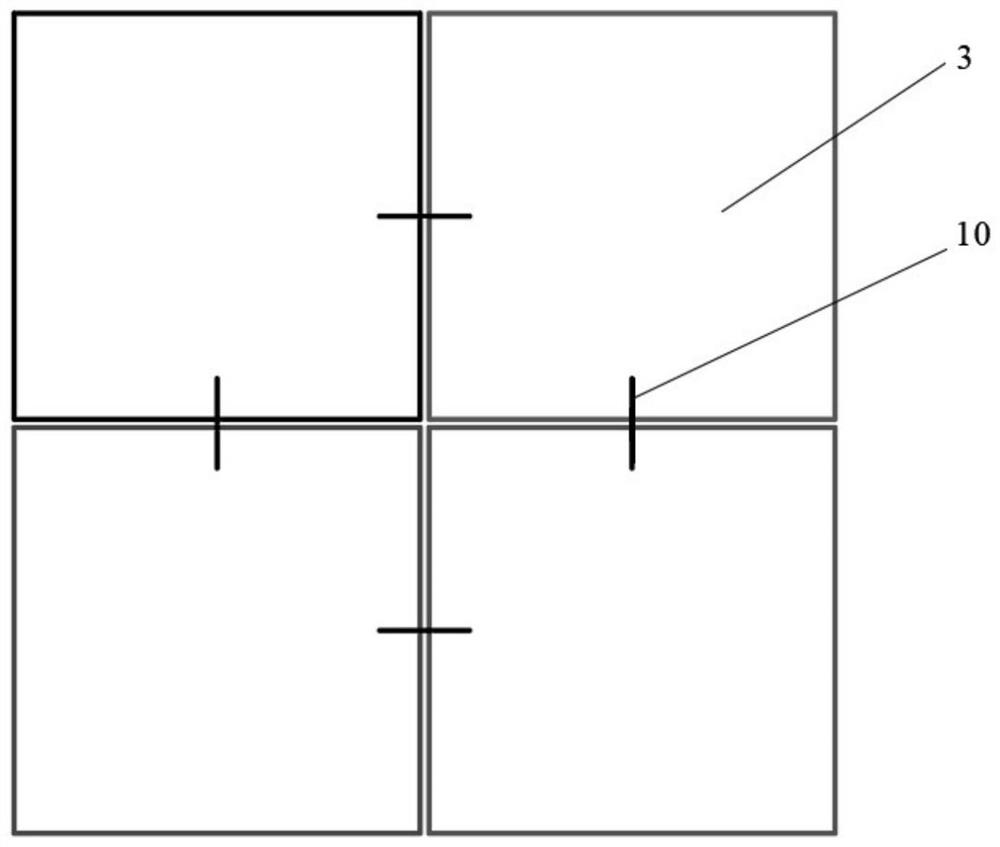

[0036] Specifically, the filling structure includes a filling body 1, a bottom pillar ore body 2, and a cushion layer 3 between the filling body 1 and the bottom pillar ore body 2, and the cushion layer 3, wherein the filling body 1 connects the bottom pillar ore body 2 The goaf above is backfilled, and a cushion layer 3 is provided at the bottom of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com