Tartary buckwheat-based activated carbon material as well as preparation method and application thereof

A technology based on activated carbon and tartary buckwheat, applied in chemical instruments and methods, hybrid/electric double layer capacitor manufacturing, carbon compounds, etc., can solve the problem of material utilization efficiency reduction, affecting the service life of electric double layer supercapacitors, and the specific capacity of electrode materials Loss and other problems, to achieve the effect of repairing macropore defects, improving electrochemical cycle stability, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

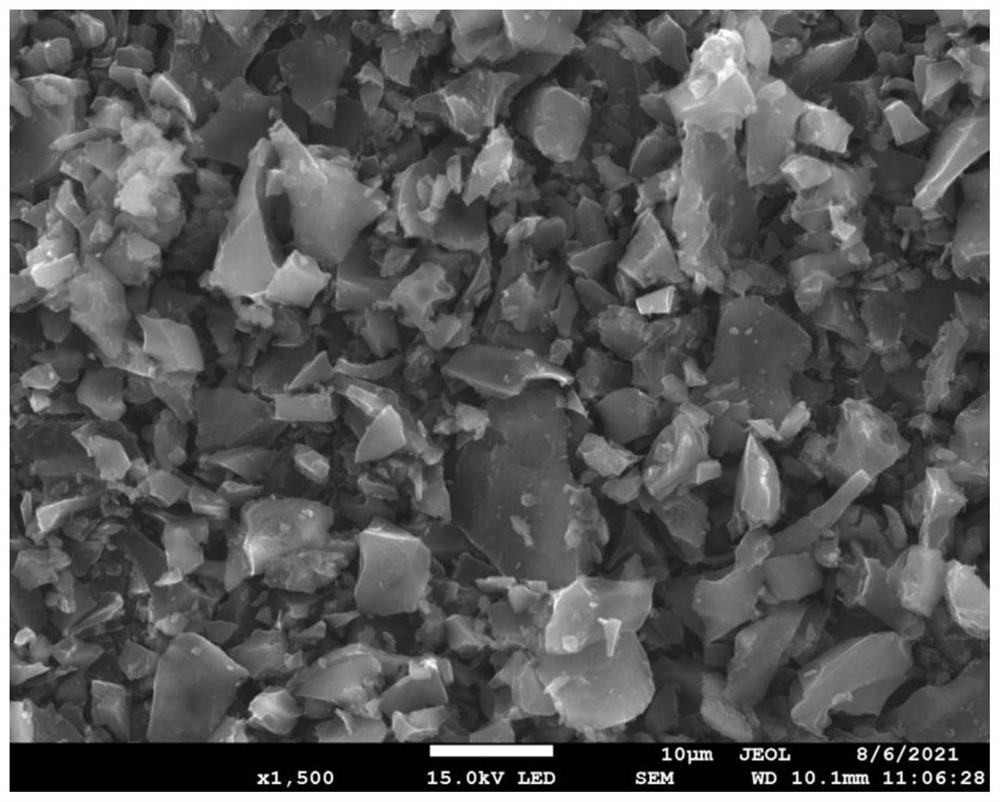

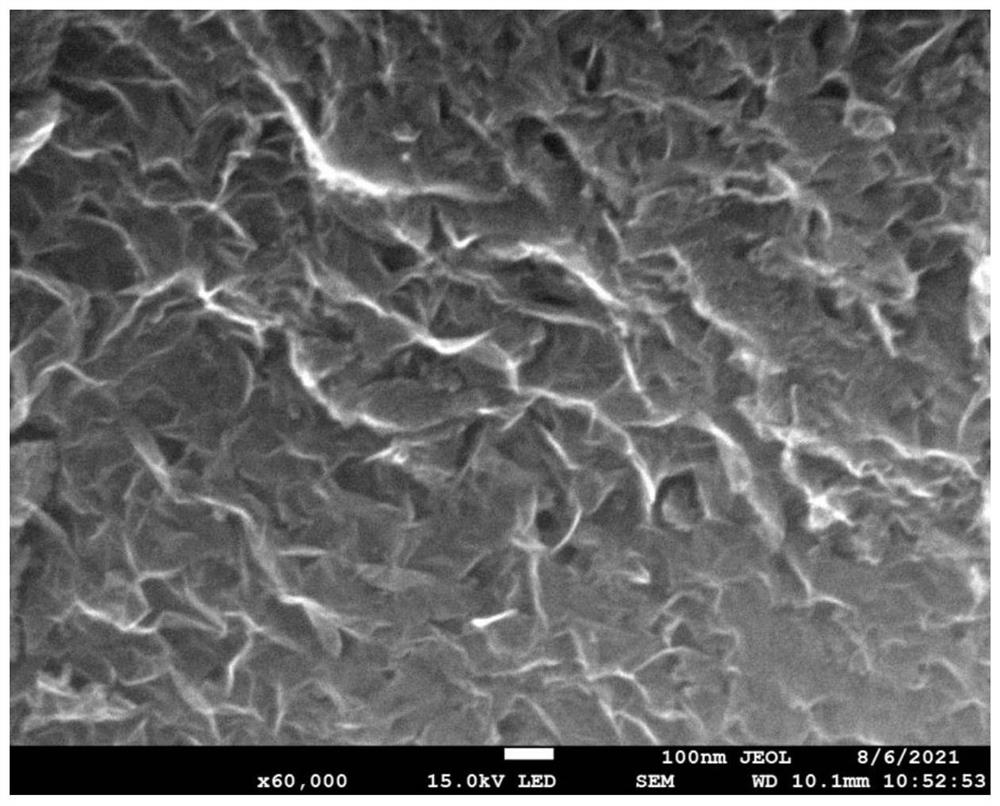

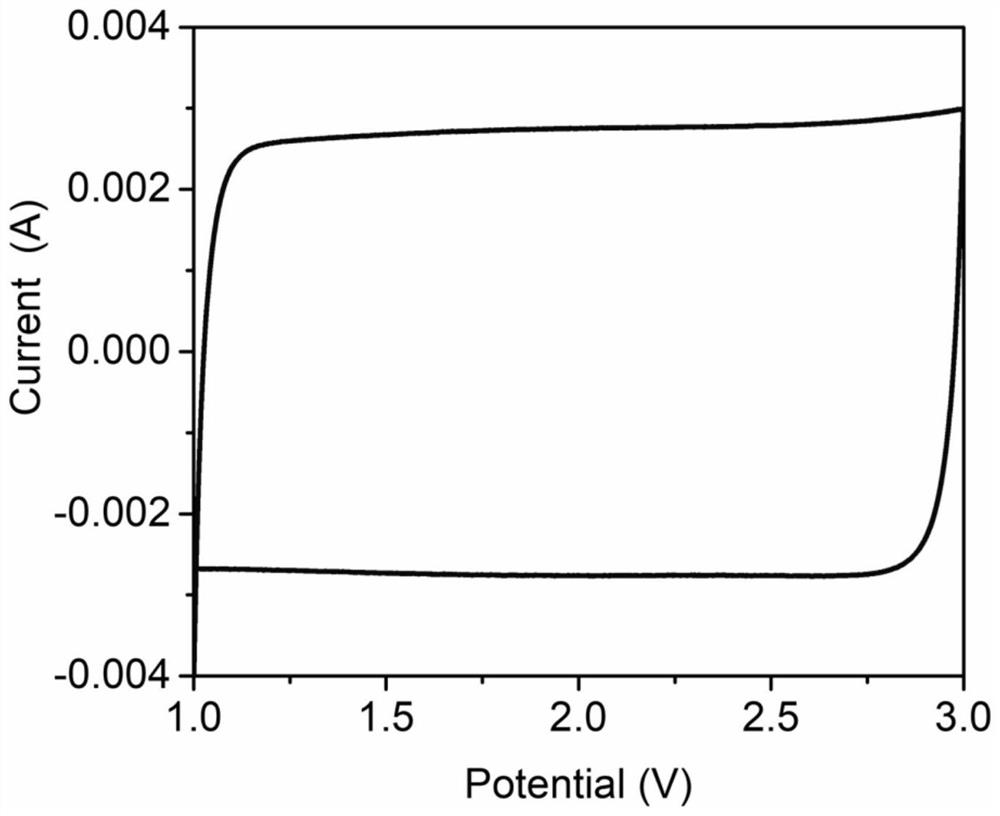

[0038] (1) Coarse carbon preparation: Under an argon atmosphere, tartary buckwheat powder with a particle size of 80 meshes was heated to 400 ° C at a constant temperature for 2 hours at a temperature of 3 ° C / min to obtain a coarse carbon powder;

[0039] (2) Pickling and impurity removal: After the crude carbon powder is naturally cooled and taken out, it is placed in a high-pressure reactor with 10wt% hydrochloric acid, soaked and washed at 80°C for 24 hours, then washed with water until neutral, and then dried ;

[0040] (3) Activation: Mix the carbon material obtained after pickling with sodium hydroxide at a mass ratio of 1:1.5 and soak for 2 hours, then dry it, then raise the temperature to 900°C at 3°C / min for 2 hours under an argon atmosphere , and then washed with water to neutral, and then dried;

[0041] (4) Pickling purification: the activated carbon material obtained after activation is placed in a high-pressure reactor together with 10wt% hydrochloric acid, s...

Embodiment 2

[0047] (1) Coarse carbon preparation: Under an argon atmosphere, tartary buckwheat powder with a particle size of 80 meshes was heated to 400 ° C at a constant temperature for 2 hours at a temperature of 3 ° C / min to obtain a coarse carbon powder;

[0048] (2) Pickling and impurity removal: After the crude carbon powder is naturally cooled and taken out, it is placed in a high-pressure reactor with 10wt% hydrochloric acid, soaked and washed at 80°C for 24 hours, then washed with water until neutral, and then dried ;

[0049] (3) Activation: Mix the carbon material obtained after pickling with sodium hydroxide at a mass ratio of 1:1.5 and soak for 2 hours, then dry it, then raise the temperature to 1100°C at 3°C / min for 2 hours under an argon atmosphere , then washed with water to neutral, and then dried;

[0050] (4) Pickling purification: the activated carbon material obtained after activation is placed in a high-pressure reactor together with 10wt% hydrochloric acid, soak...

Embodiment 3

[0056] (1) Coarse carbon preparation: Under an argon atmosphere, tartary buckwheat powder with a particle size of 80 meshes was heated to 400 ° C at a constant temperature for 2 hours at a temperature of 3 ° C / min to obtain a coarse carbon powder;

[0057] (2) Pickling and impurity removal: After the crude carbon powder is naturally cooled and taken out, it is placed in a high-pressure reactor with 10wt% hydrochloric acid, soaked and washed at 80°C for 24 hours, then washed with water until neutral, and then dried ;

[0058] (3) Activation: Mix the carbon material obtained after pickling with sodium hydroxide at a mass ratio of 1:1.5 and soak for 2 hours, then dry it, then raise the temperature to 1300°C at 3°C / min for 2 hours under an argon atmosphere , then washed with water to neutral, and then dried;

[0059] (4) Pickling purification: the activated carbon material obtained after activation is placed in a high-pressure reactor together with 10wt% hydrochloric acid, soak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap