Automatic stacking device for high-molecular water-absorbing and water-retaining solid water

A polymer water-absorbing and palletizing device technology, which is applied in the field of polymer water-absorbing and water-retaining solid water automatic palletizing devices, can solve the problems that the reciprocating motion cycle affects the palletizing efficiency, the machine is difficult to control and adjust, and the packaging bag is easy to overturn, etc. , to meet the needs of automatic palletizing of polymer water-absorbing and water-retaining solid water, improve the binding effect, and avoid the effect of overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

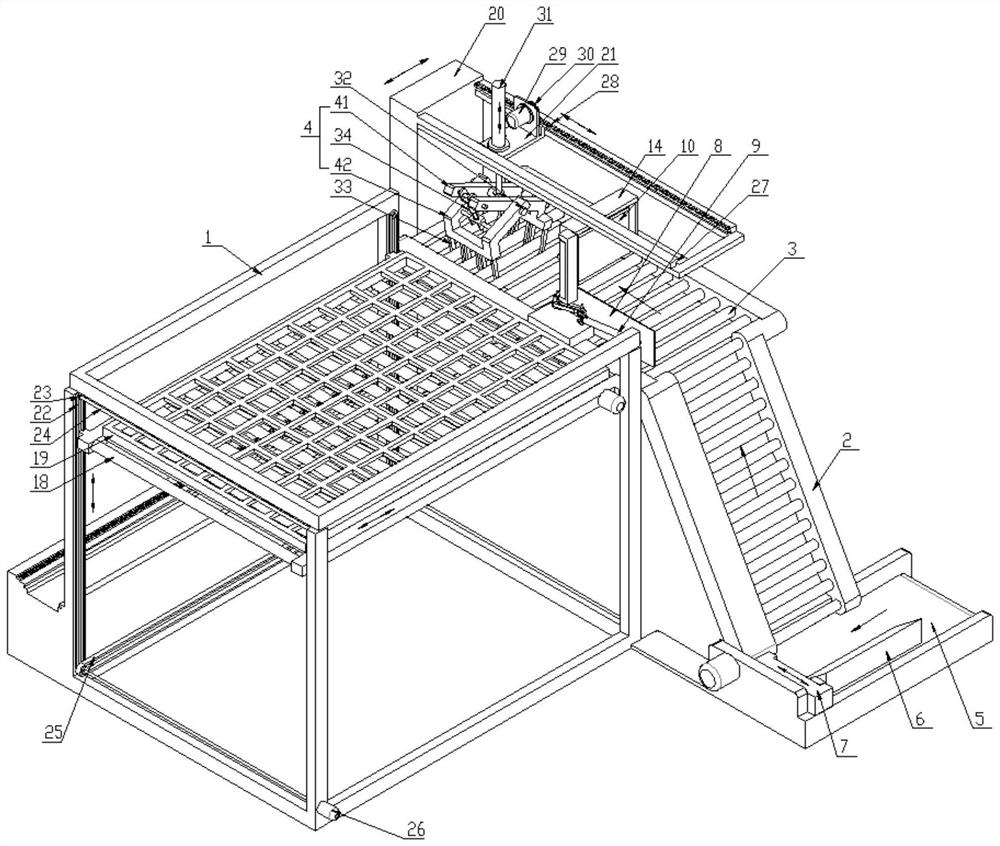

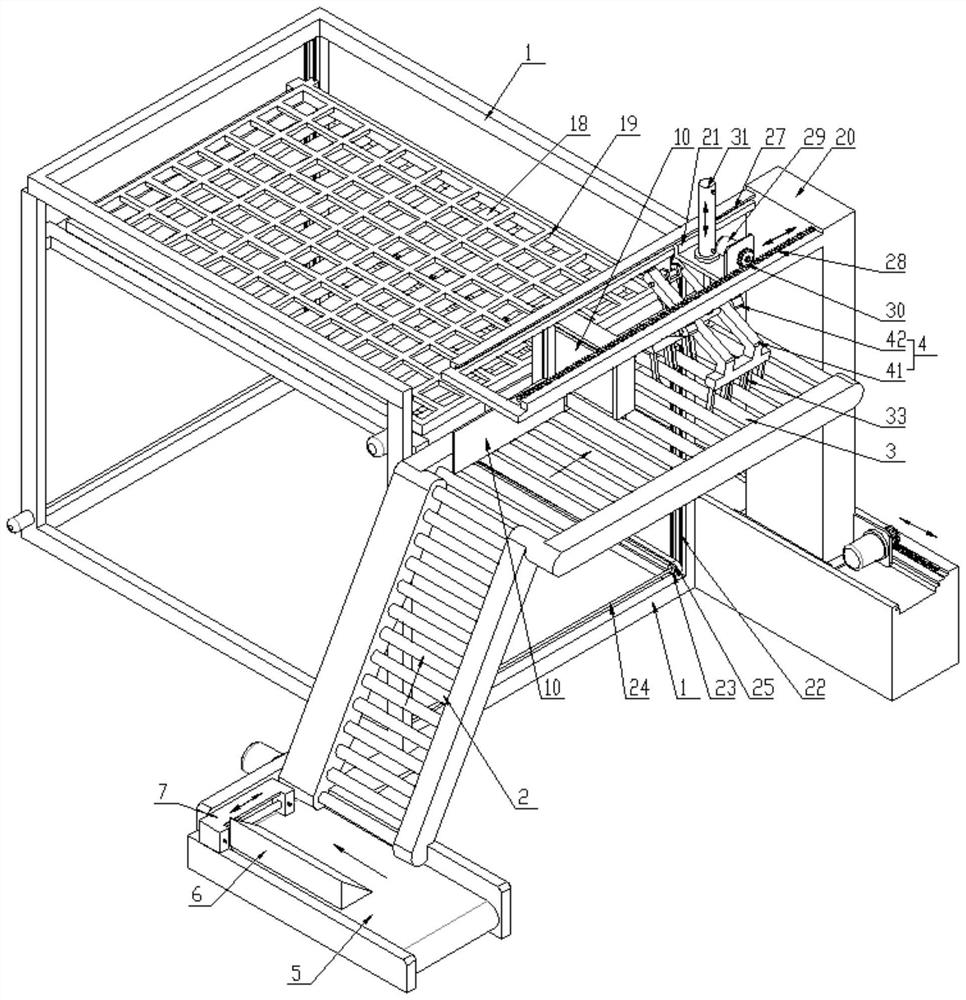

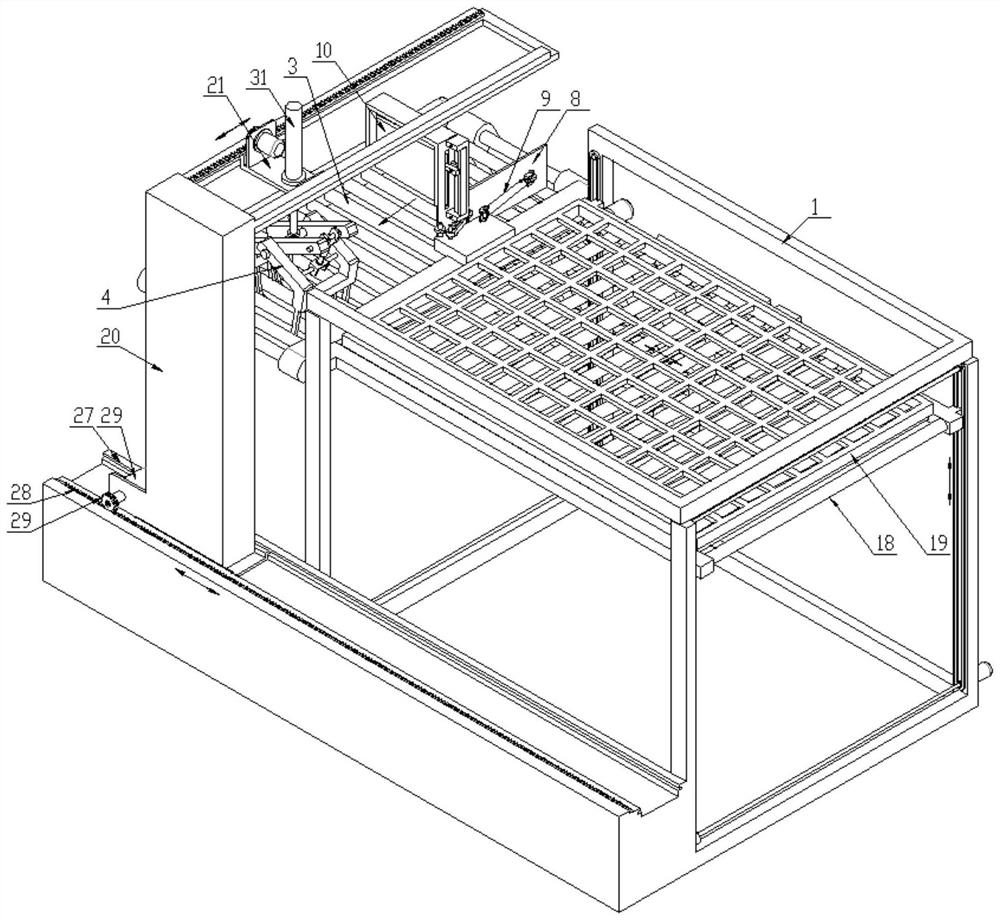

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] An automatic palletizing device for polymer water-absorbing and water-retaining solid water, comprising a frame 1 on which an inclined hoist 2, a high-level conveyor 3 located at the tail of the hoist 2, a high-level conveyor 3 located on the top Clamping mechanism 4, wherein, the end of the elevator 2 is provided with a low conveyor 5 vertically transported to the high conveyor 3, and the end of the low conveyor 5 is provided with a first pusher that moves horizontally to and from the elevator 2. plate 6;

[0027] The first push plate 6 is arranged obliquely near the side wall of the hoist 2, and a first rodless cylinder 7 perpendicular to the conveying direction of the low conveyor 5 is provided on one side of the low conveyor 5, and the first rodless cylinder The cylinder slider of 7 is fixedly connected with the first push plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com