Safety belt structure with waist load buffering function and safety belt lock catch

A seat belt lock and seat belt technology, applied in the field of seat belts, can solve the problems of lack of protection of seat belts, internal organ damage, etc., and achieve the effect of reducing impact and facilitating deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

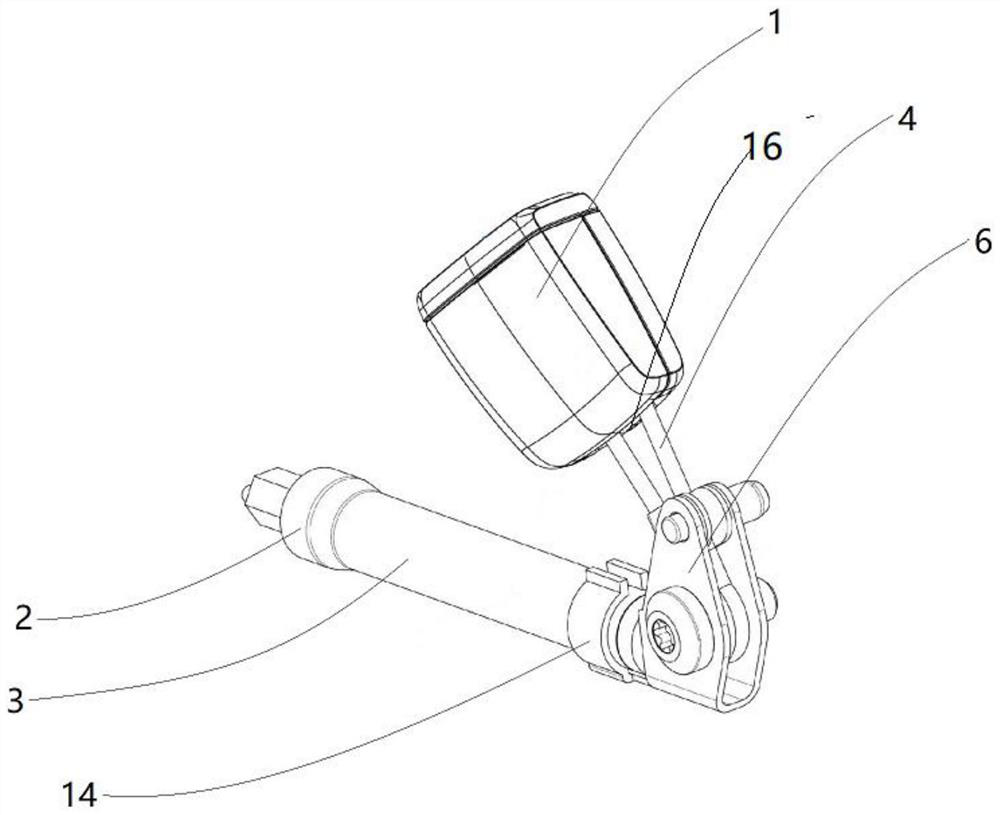

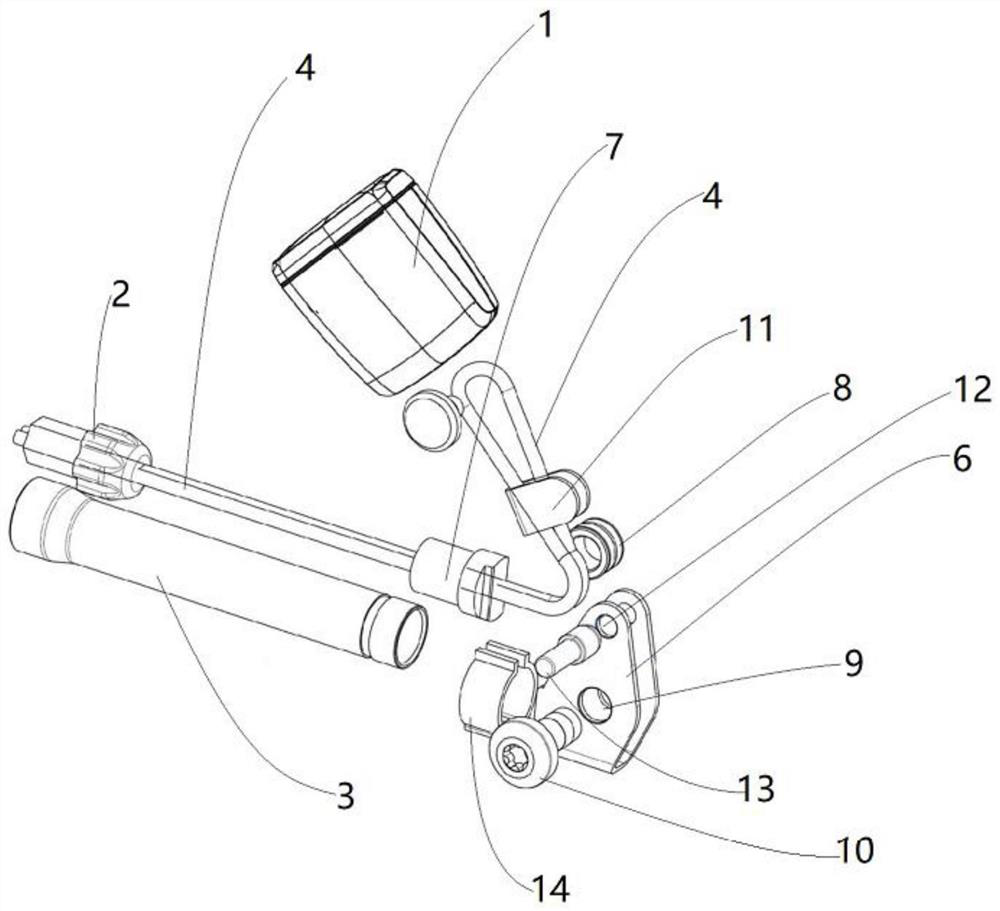

[0041] like figure 1 , figure 2 and image 3 As shown, a seat belt structure with the function of cushioning the waist load is installed on the seat of the vehicle and connected with the seat belt buckle 1, the seat belt buckle 1 is connected with a seat belt, and the seat belt buckle 1 has an upper opening and a lower opening 16, the safety belt enters the interior of the safety belt buckle 1 through the upper opening and is connected to the safety belt buckle 1, including:

[0042] guiding components;

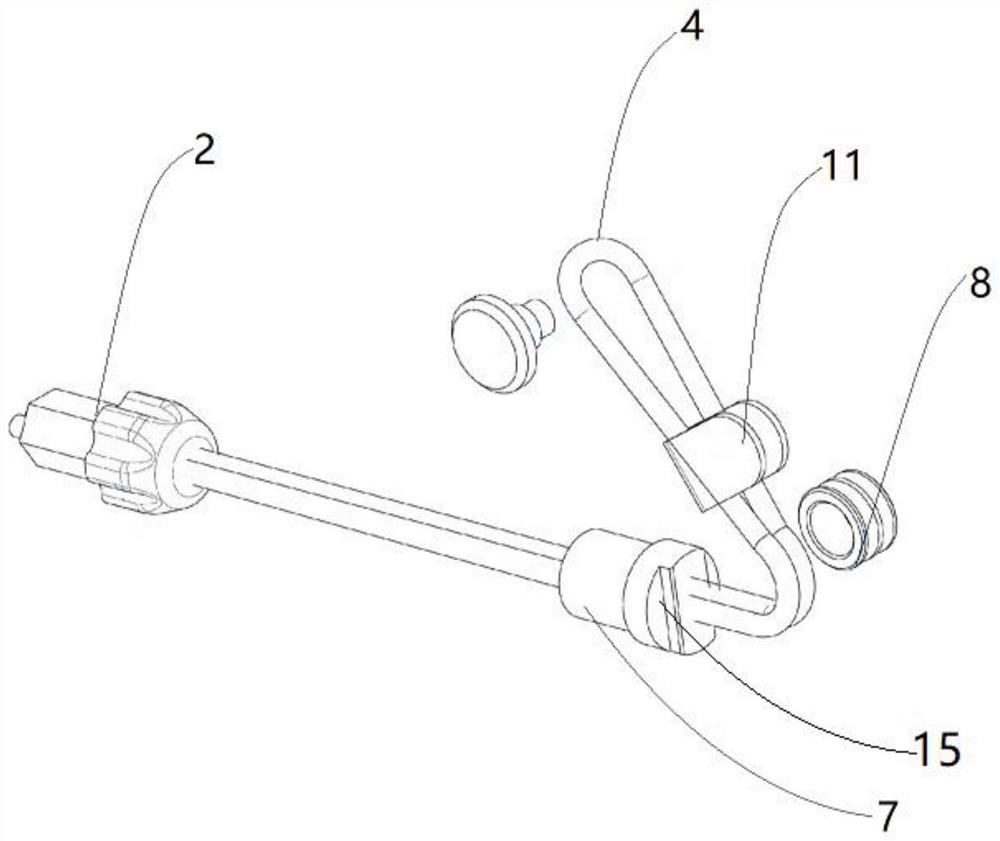

[0043] Shock-absorbing end 2;

[0044] The buffer component 3 is located between the shock-absorbing end 2 and the guide assembly;

[0045] The connecting part 4, one end is connected with the shock-absorbing end 2, and the other end is connected with the seat belt buckle 1 after passing through the guide assembly, and the connecting part 4 enters the inside of the seat belt buckle 1 through the lower opening 16, buffering The component 3 is sleeved on the connecting co...

Embodiment 2

[0067] Such as Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the buffer member 3 in this embodiment uses a spring, and the two ends of the spring are pressed against the shock-absorbing end 2 and the stop member 7 respectively, and the spring is easy to deform. The impact response is more sensitive, and the spring can be used repeatedly, saving costs.

Embodiment 3

[0069] The difference between this embodiment and Embodiments 1 and 2 is that the buffer member 3 in this embodiment is a rubber tube, and the two ends of the rubber tube and the two ends of the spring are tightly pressed between the shock-absorbing end 2 and the stopper 7, The rubber tube has good wear resistance and elasticity, and has strong resistance to pulling and extrusion, and is suitable for use as the cushioning component 3 of the present invention.

[0070] A working process of the present invention: when the vehicle collides or brakes suddenly, the seat belt pulls the seat belt buckle 1, the seat belt buckle 1 pulls the wire rope, the wire rope is tensioned, and the shock-absorbing end connected with the wire rope 2 stops Moving part 7 approaches, and in the process of approaching, the shock-absorbing port squeezes the metal tube arranged on the connecting part 4, and the metal tube absorbs the vibration and impact caused by the collision and deforms, effectively sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com