Stiffening ring welding device for pressure steel pipe

A welding device and penstock technology, applied in welding equipment, welding equipment, auxiliary devices, etc., can solve the problems of poor quality of welding horizontal stiffening ring fillet welds, affecting the quality of penstocks leaving the factory, inconsistent welding speed of welders, etc. Relative friction, improve the convenience of feeding, and achieve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0034] It should be understood that terms such as "having", "comprising" and "including" as used herein do not assign the presence or addition of one or more other elements or combinations thereof.

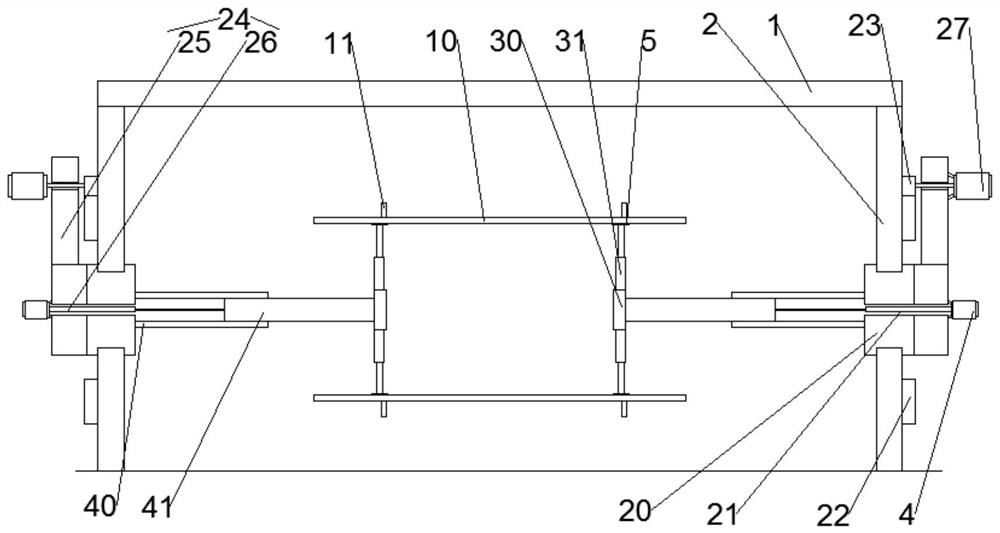

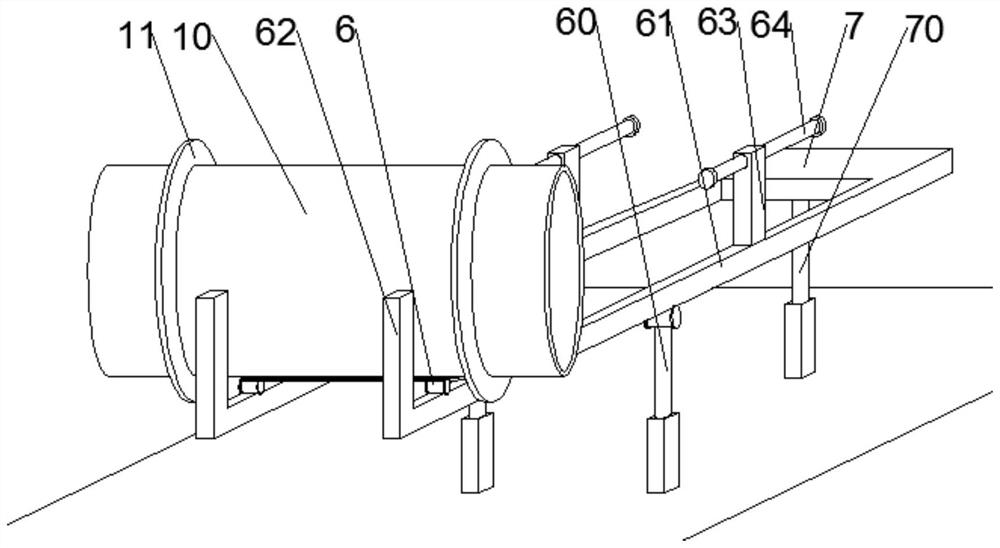

[0035] like figure 1 , 3 As shown, the present invention provides a pressure steel pipe stiffening ring welding device, including a gantry frame 1, a welding device that is telescopically erected on the top of the gantry frame 1, and rolling positioning devices respectively arranged on opposite sides of the gantry frame 1. Each rolling position The device includes:

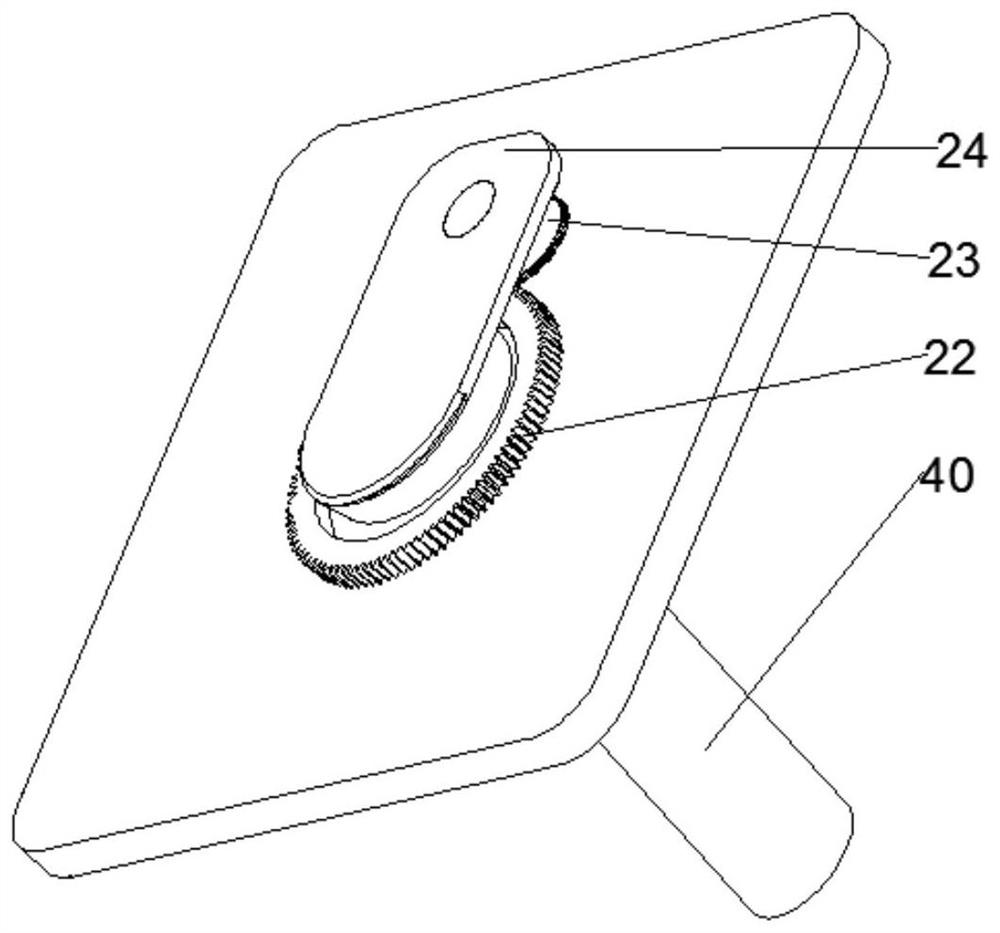

[0036] Mounting plate 2, which is fixed on one side of the gantry 1, and a turntable 20 is rotatably installed on the mounting plate 2, which is used to provide space and position for the installation of rolling asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com