Cover assembly of camera, and camera

A cover assembly and camera technology, applied in the field of cameras, can solve problems such as image quality interference, increase in the external size of the camera, and easy reflection to the inside of the lens, and achieve the effect of improving assembly strength and avoiding reflection interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0123] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

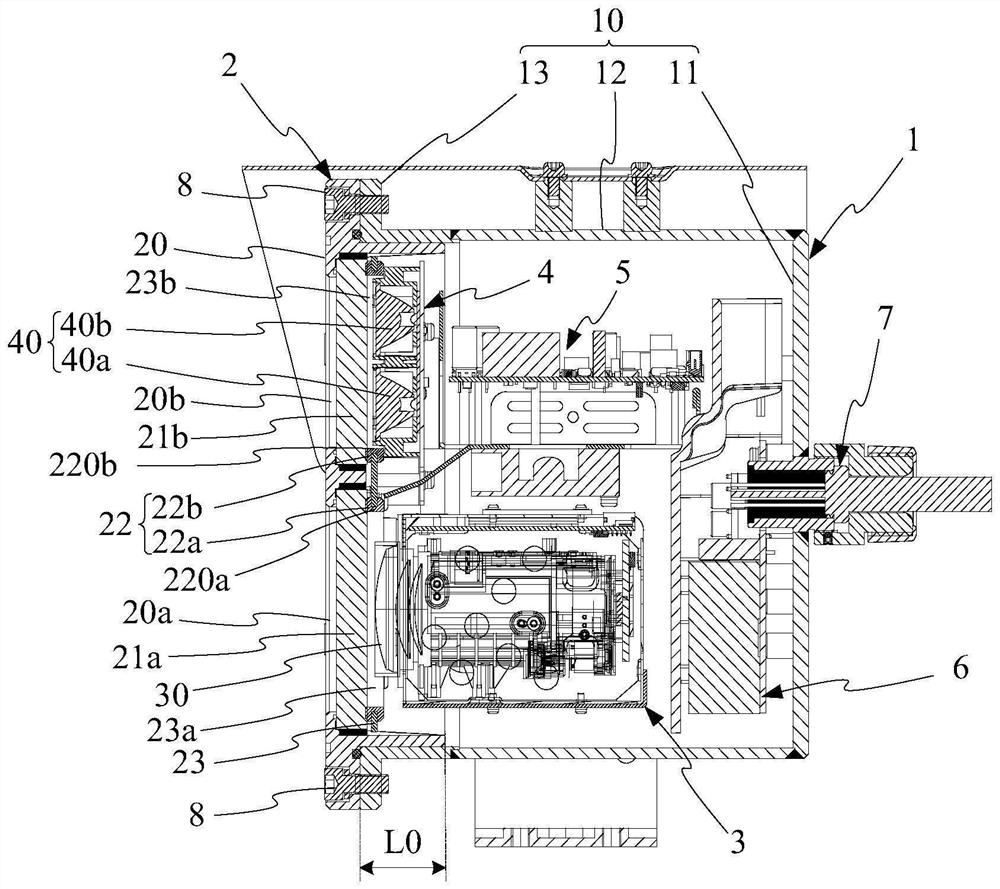

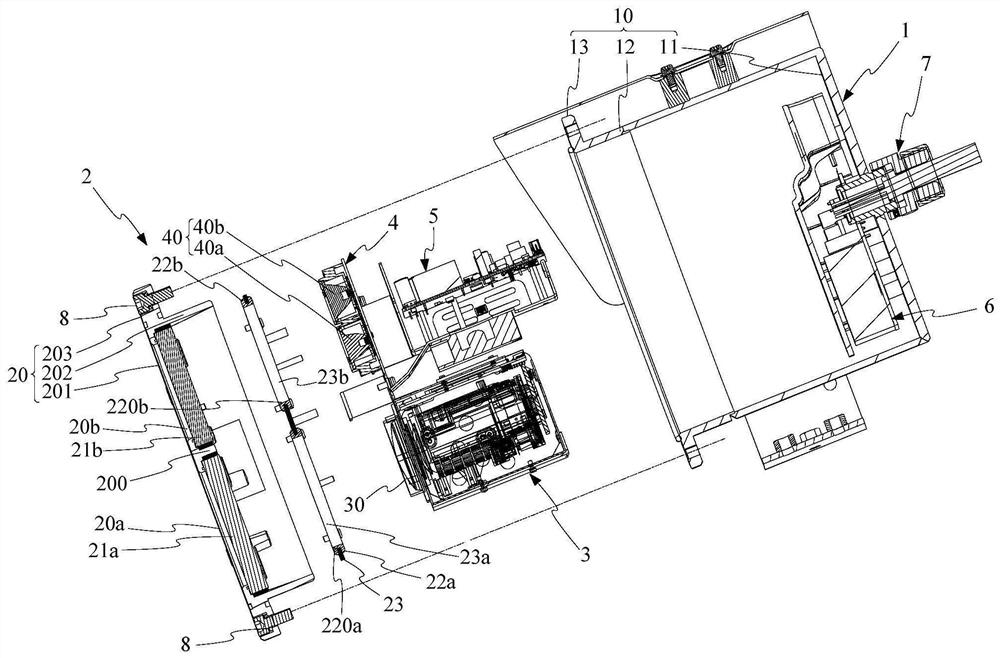

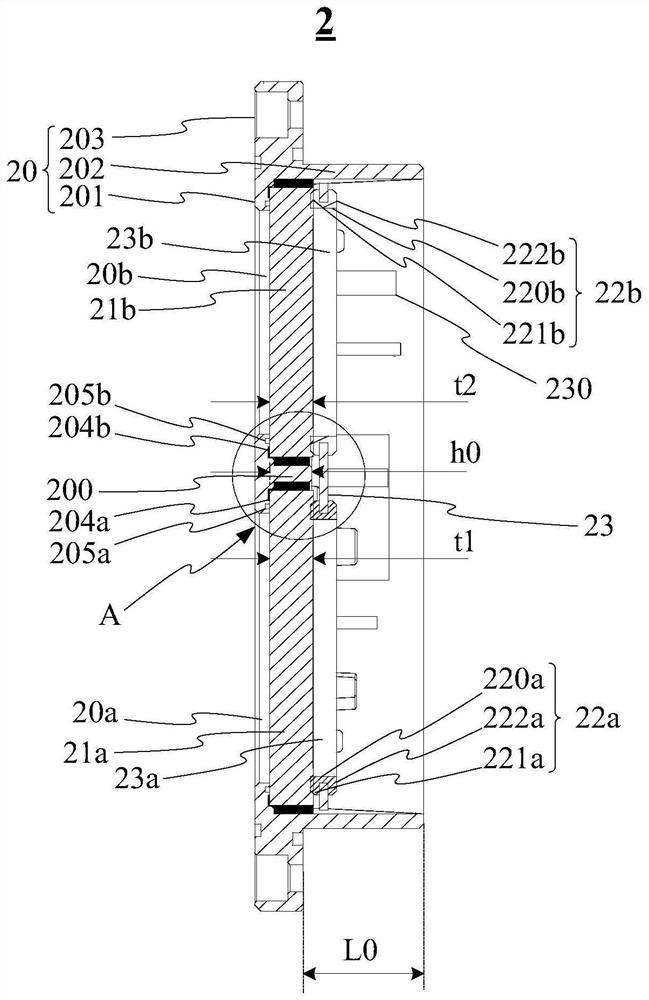

[0124] figure 1 It is a sectional view of the assembly structure of the camera in one embodiment of the present invention. figure 2 For such figure 1 A cutaway view of the exploded structure of the camera shown.

[0125] See at figure 1 simultaneous combination of figure 2 , in one embodiment, a video camera may include a body assembly 1 , a cover assembly 2 , a movement assembly 3 and a supplementary light assembly 4 .

[0126] The fuselage assembly 1 can have an open end face 100, for example, the fuselage assembly 1 can include a casing 10, the casing 10 includes a rear end plate 11, and a tube forming a shell cavity surrounded by one side (front side) of the rear end plate 11 The wall 12 , the front end opening of the barrel wall 12 forms the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com