Power-on inspection equipment for power connecting line

A technology for power connection lines and inspection equipment, which is applied in the direction of measuring electricity, measuring electric variables, and parts of electrical measuring instruments, etc. The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

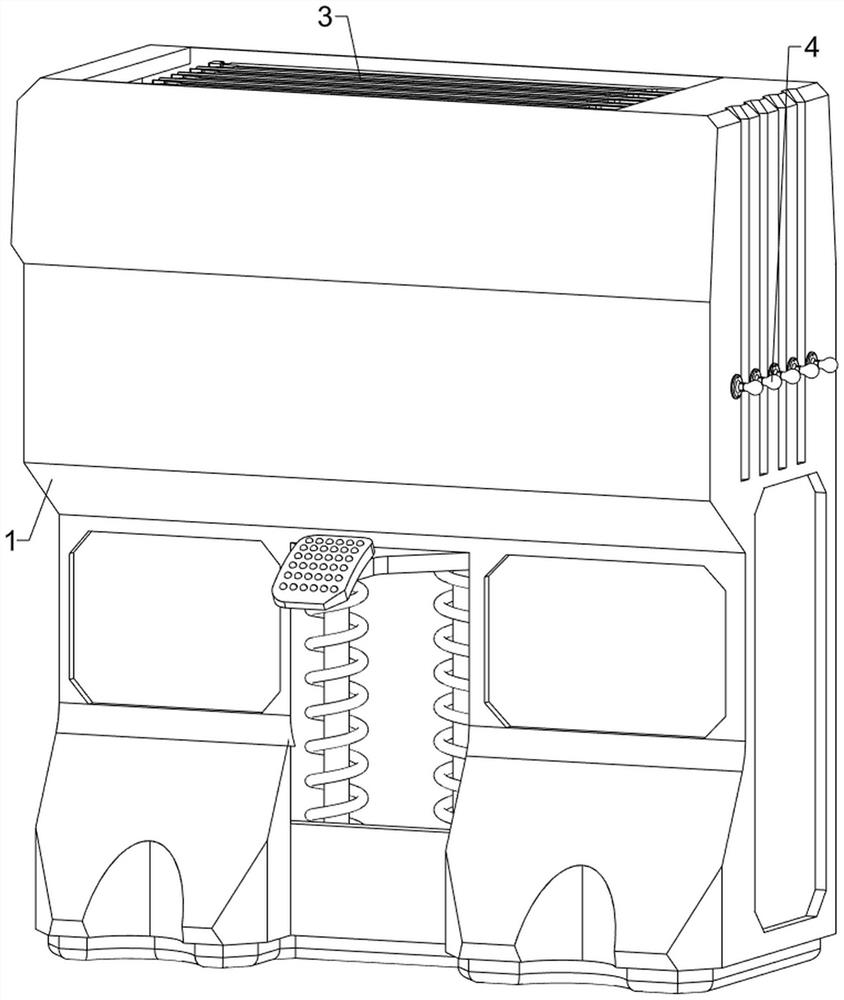

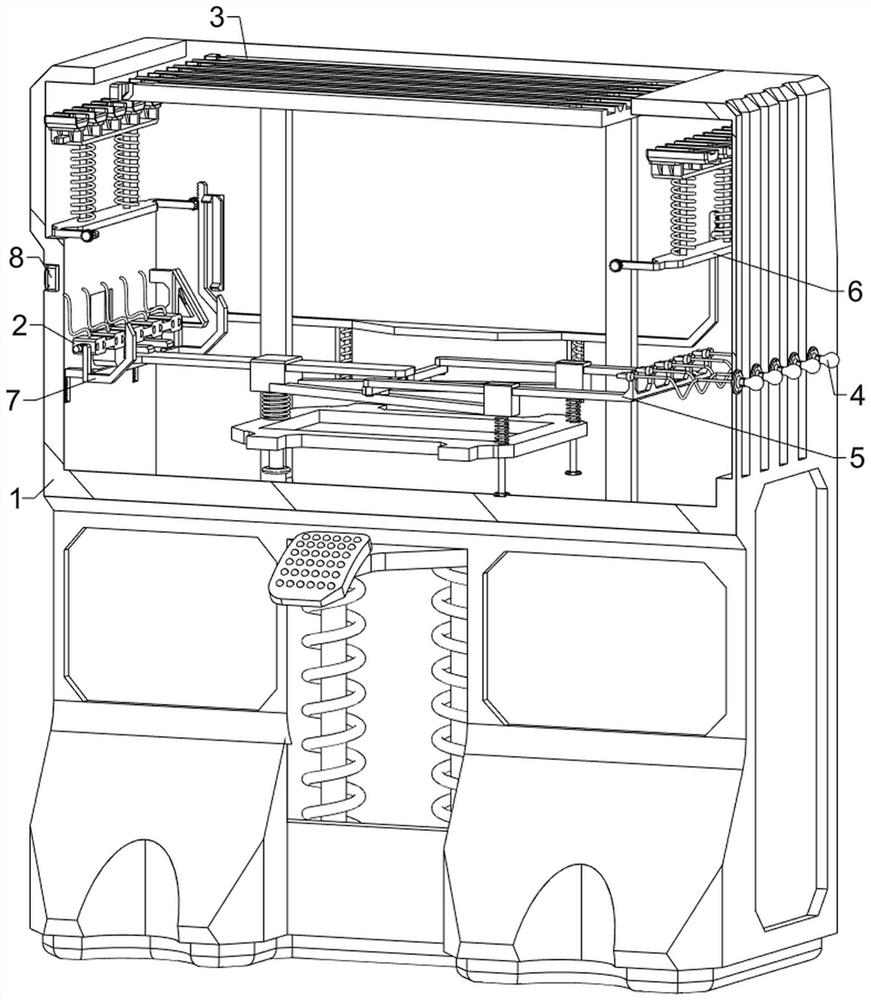

[0032] Such as Figure 1 to Figure 7 As shown, this embodiment discloses a power connection inspection device, which includes a casing 1, a socket 2, a placement component 3, a prompt component 4 and a support component 5. The middle part of the casing 1 is provided with a placement component 3, and the upper right side of the casing 1 A prompting assembly 4 is provided, and a supporting assembly 5 is provided between the inner upper side of the housing 1 and the prompting assembly 4 , and a socket 2 is provided on the supporting assembly 5 .

[0033] The placement assembly 3 includes a first guide rod 31, a foot pedal 32, a first spring 33 and a placement plate 34. The first guide rod 31 is symmetrically connected to the left and right sides of the inside of the housing 1, and the first guide rods 31 are connected in a sliding manner. Pedal 32 is arranged, and first spring 33 is connected with left and right symmetry between pedal 32 and shell 1, and first spring 33 is enclos...

Embodiment 2

[0038] Such as figure 2 , Figure 8 ~ Figure 14 As shown, in some embodiments, a fixed assembly 6 is also included, and the fixed assembly 6 includes a second guide rod 61, a wedge rod 62, a fourth spring 63, a third guide rod 64, a rack bar 65, a fifth spring 66, gear 67, support plate 68, mounting frame 69, first fixed block 610, the sixth spring 611 and the second fixed block 612, the upper front and back sides of the inner upper part of the shell 1 are connected with the second guide rod 61 symmetrically. A wedge-shaped rod 62 is slidably connected to the guide rod 61, and the wedge-shaped rod 62 cooperates with the placement plate 34. A fourth spring 63 is connected between the wedge-shaped rod 62 and the housing 1, and the fourth spring 63 is sleeved on the second guide rod 61. Above, there are third guide rods 64 symmetrically connected to the front, rear and left and right sides of the inner upper part of the housing 1, and a rack bar 65 is slidably connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com