A composite fault diagnosis method for rolling bearings embedded in fault semantic space

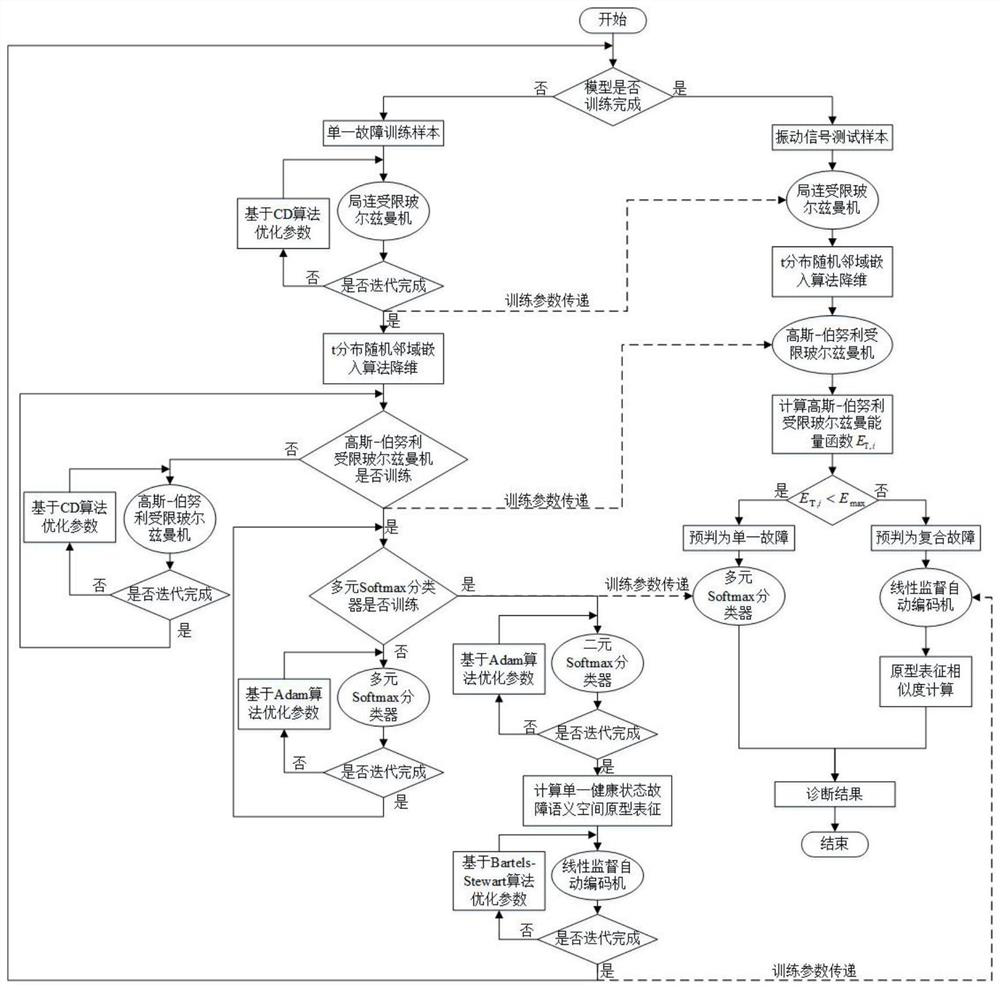

A technology of fault semantics and composite faults, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve problems such as missed fault diagnosis, low accuracy of the model as a whole, ignoring the connection between composite faults and single faults, etc., to achieve Improving diagnostic accuracy and overcoming misdiagnosis or missed diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

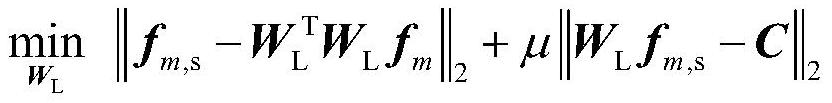

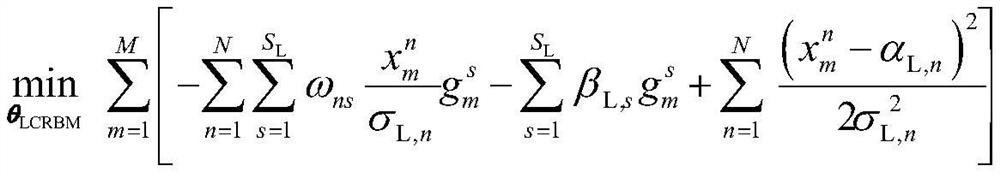

Method used

Image

Examples

Embodiment

[0062] Example: Taking the wheelset bearing in a locomotive as an example, based on the experimental data of the wheelset bearing failure of the locomotive, the validity of the method of the present invention is verified.

[0063] The data set of the experimental data samples obtained from the locomotive wheelset bearing failure is shown in Table 1, which includes 8 health states: normal state, rolling element fault, inner ring fault, outer ring fault, rolling inner ring composite fault, rolling outer ring composite fault , Composite failure of inner and outer rings, composite failure of rolling inner and outer rings. The vibration signal samples were obtained under the condition that the motor speed was 600r / min. During the test, the sampling frequency of the vibration signal samples was 12800Hz. After the test, the number of samples for each health state is 320, and each sample contains 1000 data points. In order to simulate the normal state and each single fault sample, 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com