Automobile intelligent headlamp laser light source system and application method

A laser light source, intelligent technology, applied in the direction of light source, headlights, optical elements used to change the spectral characteristics of emitted light, etc., can solve the problems of uneven illumination, high assembly requirements, low production efficiency, etc., to meet the requirements of vehicle vibration Requirements, easy alignment of optical path, convenient installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0041] When implementing, follow these steps:

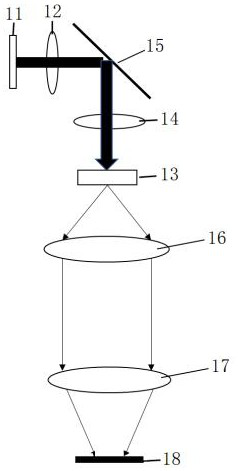

[0042] 1) The light from the laser light source 11 is directed to the first collimated and compressed optical path 12, and the compressed light is reflected by the dichroic mirror 15. The reflective surface below the dichroic mirror 15 is provided with a spectroscopic optical film, which mainly reflects laser light. The effect of light from the light source 11;

[0043] 2) The light reflected by the dichroic mirror 15 is reshaped by the focusing optical path 1# 14, and the focused spot is 1-3mm in diameter and projected onto the wavelength conversion device 13, which is a reflective structure with a heat-conducting base, and the reflected light The strength and angle satisfy the Lambertian distribution, and the heat-conducting substrate is made of a metal material with good thermal conductivity, such as copper, aluminum or composite materials, etc.;

[0044] 3) The light reflected by the wavelength converting device 13 is the conv...

no. 2 example

[0047] When implementing, follow these steps:

[0048] 1) The light from the laser light source 11 is irradiated to the first collimated and compressed optical path 12, and the compressed light is reflected by the dichroic mirror 15, and an optical film is provided on the reflecting surface below the dichroic mirror 15, and the optical film is preferably The spectroscopic optical film mainly plays the role of reflecting the light of the laser light source 11;

[0049] 2) The light reflected by the dichroic mirror 15 is reshaped by the focusing optical path 1#14, and the focused light spot is 1-3 mm in diameter and projected onto the wavelength conversion device 13. The device is a transmission structure, and the intensity and angle of the transmitted light meet the Lambertian requirements. distributed;

[0050] 3) The light transmitted by the wavelength conversion device 13 is the wavelength-converted light, which then reaches the shaping optical path 16;

[0051] 4) The lig...

no. 3 example

[0053] When implementing, follow these steps:

[0054] 1) directing the light from the laser light source 11 to the first collimated and compressed optical path 12;

[0055] 2) After the compressed light is reshaped by the focusing optical path 1# 14, the focused light spot is 1-3 mm in diameter and projected onto the wavelength conversion device 13. The device is a transmission structure, and the intensity and angle of the transmitted light satisfy the Lambertian distribution;

[0056] 3) The light transmitted by the wavelength conversion device 13 is the wavelength-converted light, which then reaches the shaping optical path 16;

[0057] 4) The light shaped by the shaping optical path 16 is then transmitted through the focusing optical path 2# 17 to obtain the desired light source, and then projected onto the DMD chip 18 .

[0058] To sum up, the scheme is simple in structure and easy to operate. It adopts a single-channel solid-state laser light source module, the optical ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap