High-locking anti-crack mandrel and closing-in method thereof

A technology of anti-crack and threaded mandrel, which is applied in the direction of locking fasteners, threaded fasteners, connecting components, etc. It can solve the dimensional changes of the closing die due to thermal expansion and contraction, the influence of heat on the material of the nut, the influence of the surface of the nut on heat, etc. problem, to achieve the effect of easy disassembly and large locking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

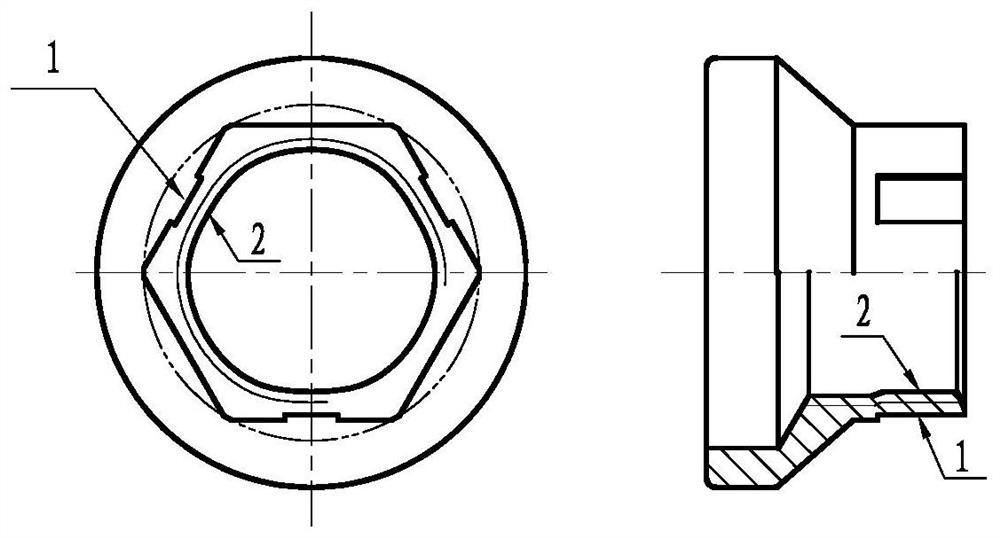

Image

Examples

Embodiment 1

[0045] Figure 4 The solid line in the middle is a schematic diagram of a mandrel for fixing a solid structure of the present invention. The mandrel has a special external thread, and the profile of the special external thread is obtained after modification on the basis of the external thread of the bolt corresponding to the internal thread of the nut. The profile angle, pitch diameter, minor diameter and pitch of the special external thread are equal to the profile angle, pitch diameter, minor diameter and pitch of the bolt external thread corresponding to the nut internal thread. The major diameter of the special external thread is smaller than the major diameter of the corresponding bolt external thread of the nut internal thread, approximately equal to the middle diameter of the corresponding bolt external thread of the nut internal thread. Figure 4 The dotted line in the middle shows the difference between the external thread of the mandrel of the present invention and ...

Embodiment 2

[0048] Figure 8 It is a schematic diagram of the pull-out state of the mandrel inner core of an expandable split structure of the present invention, Figure 9 It is a schematic diagram of an expandable and contractible split-structure mandrel inner core plugging state of the present invention. In this embodiment, the number of petals of the multi-lobed shell of the threaded mandrel is three. Using the mandrel to close the nut is divided into three steps: step 1, penetrate into the nut Figure 8 As shown in the mandrel, the mandrel penetration position should include the position on the nut to be closed, and then insert the inner core into the mandrel so that the mandrel becomes Figure 9 state shown, or let the mandrel become Figure 9 After the mandrel is screwed into the nut; step 2, use the closing mold to close the nut, and the closing position should correspond to the middle position of the threaded mandrel multi-lobed shell 5 of the mandrel, but not the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com