Titanium dioxide composite material and preparation method thereof

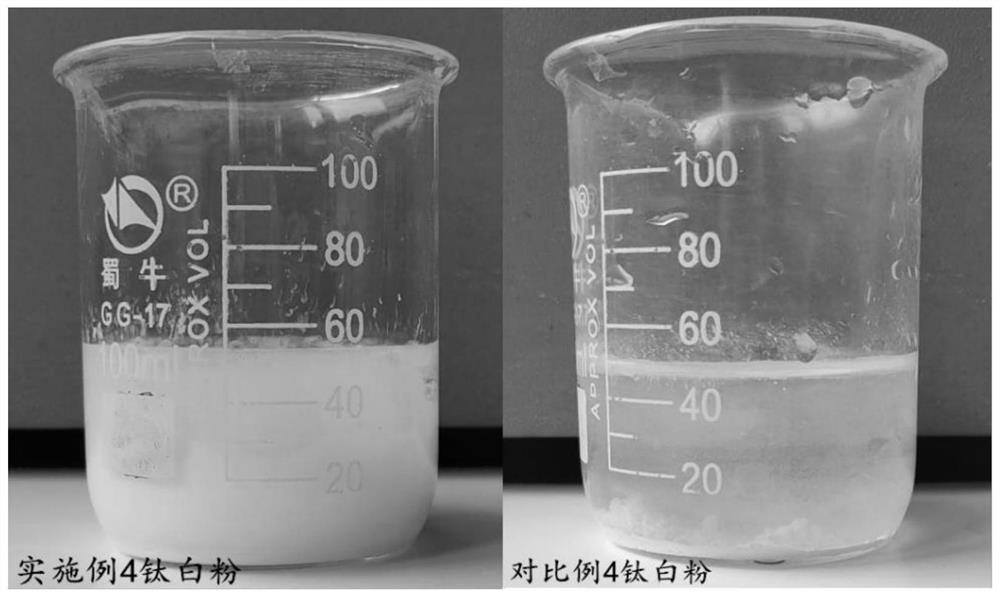

A composite material, titanium dioxide technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of reduced paint gloss, increased manufacturing cost, poor dispersibility, etc., to achieve excellent dispersion performance, The effect of good dispersion stability and excellent thermal storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

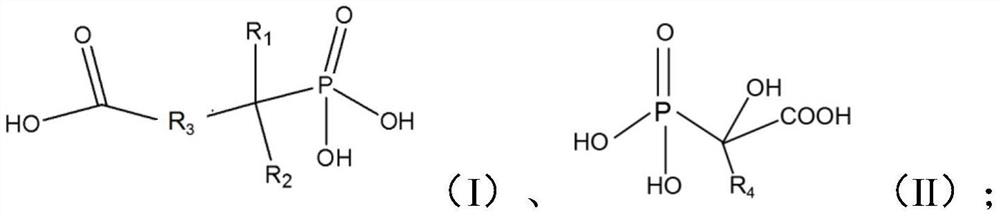

[0058] The titanium dioxide composite material-titanium dioxide slurry provided by this embodiment is mainly composed of 3-phosphonopropionic acid (structural formula is ) and titania material with a double coating of alumina and silica.

[0059] The preparation method of this titanium dioxide slurry comprises the following steps:

[0060] Get the inorganic coating that does not add dispersant and be the titanium dioxide slurry of alumina and silicon oxide (that is, have the titanium dioxide material of aluminum oxide and silicon oxide double-layer cladding layer) 400g (TiO2 in the slurry 2 The solid content is 50%, the particle size is 0.33μm, the particle size distribution is 1.49, TiO 2 is rutile), to which TiO2 in titanium dioxide slurry is added 2 0.5% by mass of 3-phosphonopropionic acid aqueous solution (mass fraction is 20%), after mechanical stirring at 20°C for 10 min, use 2-amino-2-methyl-1-propanol to adjust the pH to 6.0, and then Ultrasound for 45min. Stir m...

Embodiment 2

[0062] The titanium dioxide composite material-titanium dioxide slurry provided in this embodiment is mainly composed of 2-hydroxyphosphonoacetic acid (structural formula: ) and titania material with a double coating of alumina and silica.

[0063] The preparation method of this titanium dioxide slurry comprises the following steps:

[0064] Get the inorganic coating that does not add dispersant and be the titanium dioxide slurry of alumina and silicon oxide (that is, have the titanium dioxide material of aluminum oxide and silicon oxide double-layer cladding layer) 400g (TiO2 in the slurry 2 The solid content is 50%, the particle size is 0.33μm, the particle size distribution is 1.49, TiO 2 is rutile), to which TiO2 in titanium dioxide slurry is added 2 1% by mass of 3-phosphonopropionic acid aqueous solution (mass fraction is 50%), after mechanically stirring at 10°C for 12min, adjust the pH to 6.5 with sodium hydroxide solution, raise the temperature to 65°C, and mechani...

Embodiment 3

[0066] The titanium dioxide composite material-titanium dioxide slurry provided in this embodiment is mainly composed of phosphoryl succinic acid (structural formula is ) and titania material with a double coating of alumina and silica.

[0067] The preparation method of this titanium dioxide slurry comprises the following steps:

[0068] Get the inorganic coating that does not add dispersant and be the titanium dioxide slurry of alumina and silicon oxide (that is, have the titanium dioxide material of aluminum oxide and silicon oxide double-layer cladding layer) 400g (TiO2 in the slurry 2 The solid content is 50%, the particle size is 0.33μm, the particle size distribution is 1.49, TiO 2 is rutile), to which TiO2 in titanium dioxide slurry is added 2 2% by mass of 3-phosphonopropionic acid in ethanol (50% by mass), mechanically stirred at 35° C. for 20 min, adjusted to pH 8.0 with potassium hydroxide solution, and ultrasonicated for 50 min. Stir mechanically for another 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com