Easily degradable packaging material and preparation method thereof

A packaging material and easily degradable technology, applied in the field of packaging materials, can solve the problems of the impact of animal and microbial life activities, poor natural degradability of plastic materials, and not easy to reduce, and achieve improved mechanical properties, high structural strength, and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

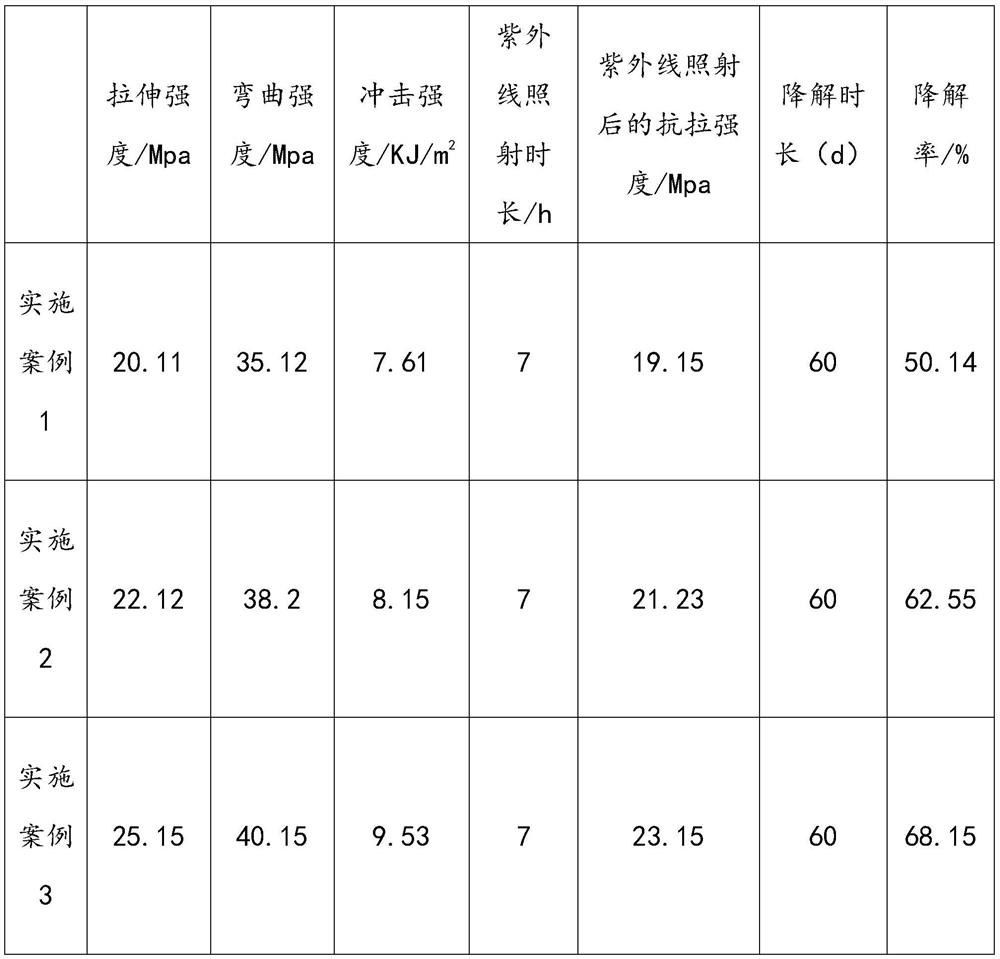

Examples

Embodiment example 1

[0057] Weigh 50 parts of high-viscosity starch and 100 parts of deionized water and put them into the reaction kettle, stir at a temperature of 68°C to obtain a starch solution, add 15 parts of sodium hydroxide solution dropwise to the starch solution, and adjust the pH value of the starch solution to 9.1 , and then uniformly stirred at a speed of 75r / min for 2min, weighed 10 parts of titanium dioxide, 15 parts of dextran, 10 parts of fucoidan and 5 parts of coupling agent and put them into the reaction kettle, stirred until the materials were evenly dispersed, and continued to Keep the temperature at 65°C for 0.75h, then add 3 parts of acid inhibitor, adjust the pH value to 6.52, then add 1 part of aluminum sulfate, continue to heat and stir for 30 minutes, wash, concentrate, dry and pulverize the product in the reaction kettle to obtain The powdery solid is the desired modified starch;

[0058] Weigh 10 parts of boron oxide, 15 parts of wollastonite, 30 parts of isooctyl met...

Embodiment example 2

[0062]Weigh 50 parts of high-viscosity starch and 100 parts of deionized water and put them into the reaction kettle, stir at a temperature of 68°C to obtain a starch solution, add 15 parts of sodium hydroxide solution dropwise to the starch solution, and adjust the pH value of the starch solution to 9.1 , and then uniformly stirred at a speed of 75r / min for 2min, weighed 10 parts of titanium dioxide, 15 parts of dextran, 10 parts of fucoidan and 5 parts of coupling agent and put them into the reaction kettle, stirred until the materials were evenly dispersed, and continued to Keep the temperature at 65°C for 0.75h, then add 3 parts of acid inhibitor, adjust the pH value to 6.52, then add 1 part of aluminum sulfate, continue to heat and stir for 30 minutes, wash, concentrate, dry and pulverize the product in the reaction kettle to obtain The powdery solid is the desired modified starch;

[0063] Weigh 10 parts of boron oxide, 15 parts of wollastonite, 30 parts of isooctyl meth...

Embodiment example 3

[0067] Weigh 50 parts of high-viscosity starch and 100 parts of deionized water and put them into the reaction kettle, stir at a temperature of 68°C to obtain a starch solution, add 15 parts of sodium hydroxide solution dropwise to the starch solution, and adjust the pH value of the starch solution to 9.1 , and then uniformly stirred at a speed of 75r / min for 2min, weighed 10 parts of titanium dioxide, 15 parts of dextran, 10 parts of fucoidan and 5 parts of coupling agent and put them into the reaction kettle, stirred until the materials were evenly dispersed, and continued to Keep the temperature at 65°C for 0.75h, then add 3 parts of acid inhibitor, adjust the pH value to 6.52, then add 1 part of aluminum sulfate, continue to heat and stir for 30 minutes, wash, concentrate, dry and pulverize the product in the reaction kettle to obtain The powdery solid is the desired modified starch;

[0068] Weigh 10 parts of boron oxide, 15 parts of wollastonite, 30 parts of isooctyl met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com