Method for extracting glycyrrhizic acid based on subcritical water extraction technology

An extraction technology, subcritical water technology, applied in the field of extracting glycyrrhizic acid based on subcritical water extraction technology, can solve the problems of low extraction rate of glycyrrhizic acid, large amount of use of organic solvents, etc., and achieve the effect of broad development and utilization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

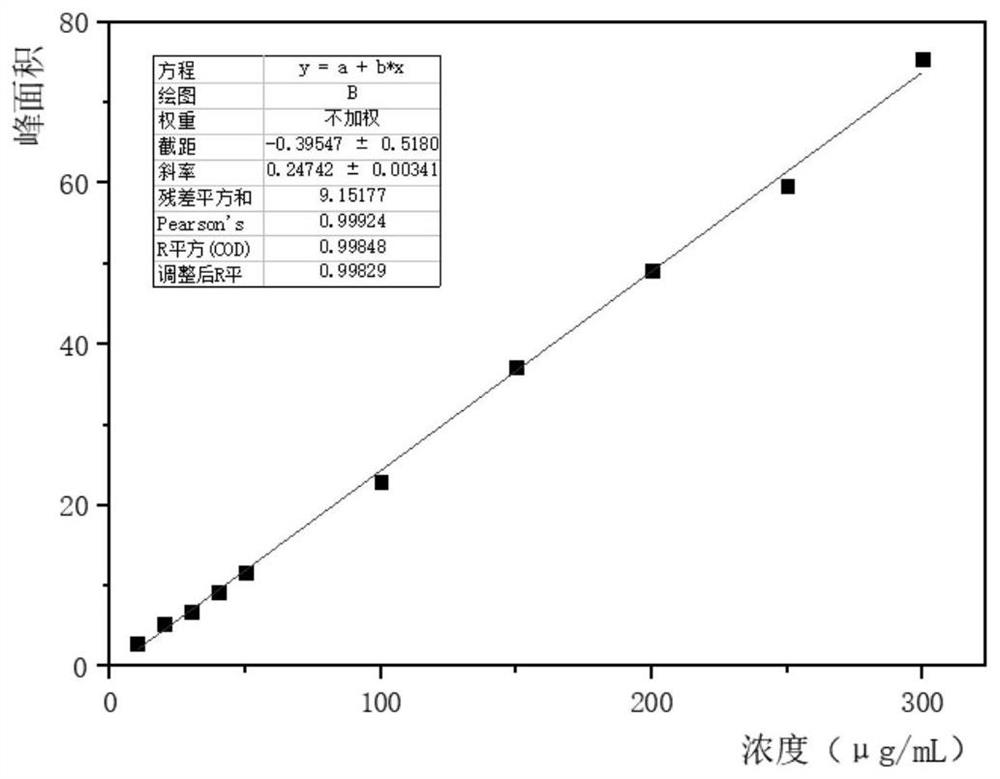

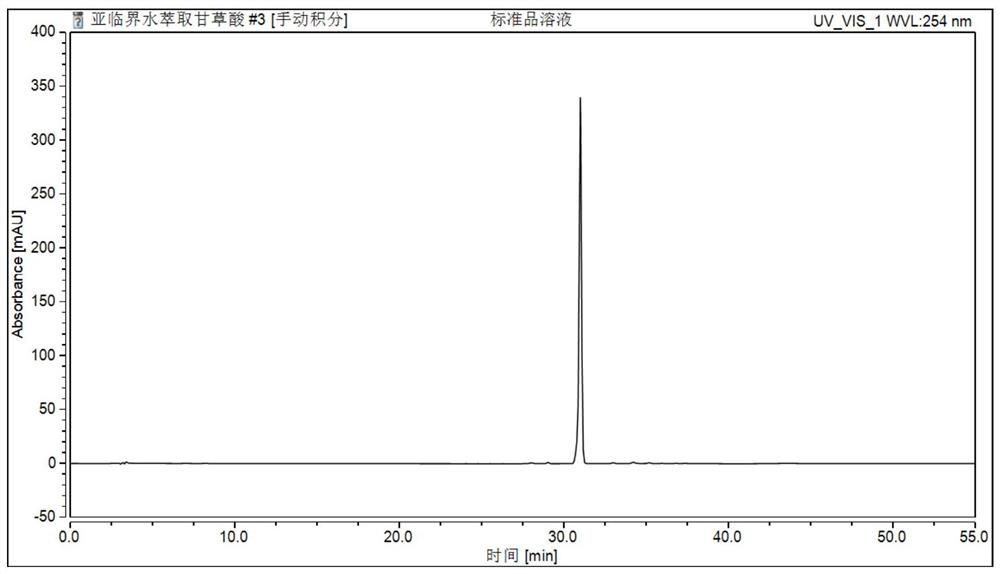

[0038] Detection of the total content of glycyrrhizic acid: according to the method of the 2020 edition of "Chinese Pharmacopoeia", take 0.2 g of licorice powder (passed through a No. 3 sieve), put it in an Erlenmeyer flask, add 100 mL of 70% ethanol precisely, seal it, and sonicate for 30 minutes. The filtrate was passed through a 0.45 μm filter membrane for liquid phase testing, and the test result was the total content of glycyrrhizic acid in the purchased licorice. Comparing the liquid chromatogram of the standard product, the peak appears at the retention time of about 31min, and the total content of glycyrrhizic acid in licorice is calculated to be 17.85mg / g.

Embodiment 2

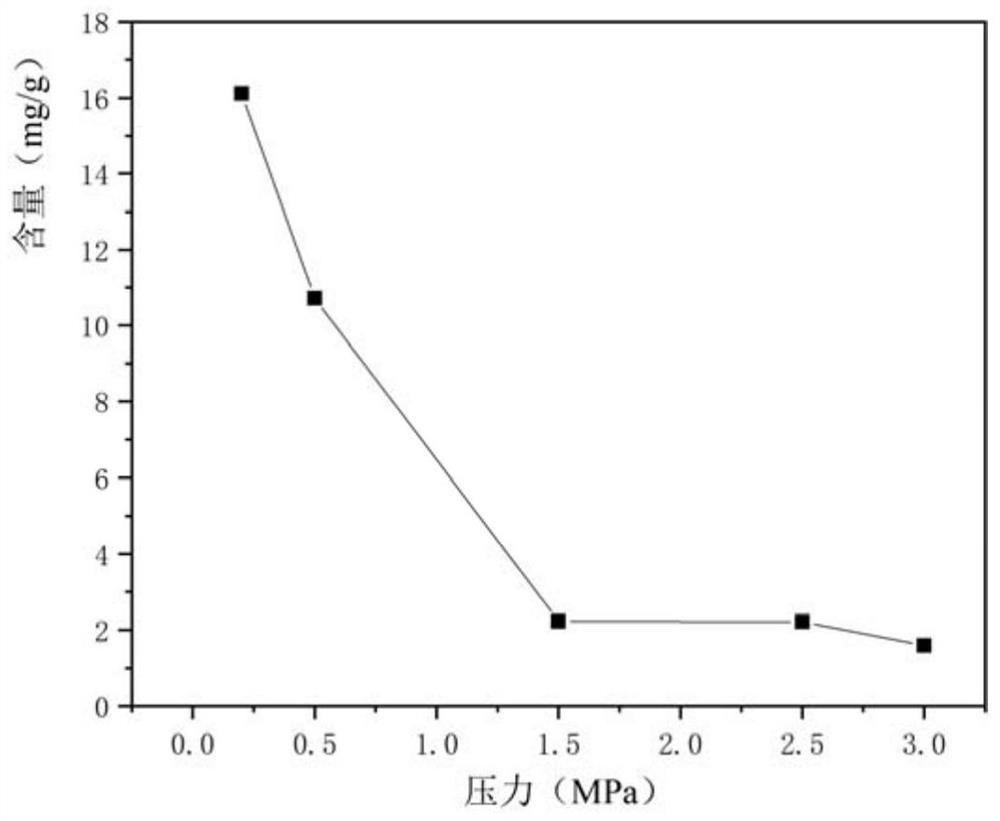

[0040] Orthogonal experiment was designed by factor rotation method to explore the influence of pressure on the extraction effect: take 30g of pretreated licorice, add 1600mL of pure water, the ratio of liquid to material is 53:1 (mL / g), heat, and stop heating after reaching 105°C , pressurize to 0.2, 0.5, 1.5, 2.5, 3Mpa respectively, heat preservation and pressure extraction for 30 minutes, turn on the cooling water after the extraction, condense the steam, then further cool down, and finally collect the extract. The extract was freeze-dried for 3 days, water was removed, dissolved in 70% ethanol, and passed through a 0.45 μm filter membrane for sampling and testing. Take the extraction effect as the evaluation index to measure the influence of pressure, such as image 3 shown.

Embodiment 3

[0042] Orthogonal experiment was designed by factor rotation method to explore the influence of liquid-material ratio on the extraction effect: add 1600mL of pure water, the extraction temperature is 105°C, the pressure is the optimal pressure in Example 1, that is, pressurize to 0.2Mpa, the amount of licorice 20, 26, 30, 35, 40g respectively, i.e. the ratio of liquid to material is 40:1~80:1 (mL / g), heat preservation and pressure extraction for 30 minutes, after the extraction is completed, turn on the cooling water to condense the steam, and then further cool down, Finally collect the extract. The extract was freeze-dried for 3 days, water was removed, dissolved in 70% ethanol, and passed through a 0.45 μm filter membrane for sampling and testing. Take the extraction effect as the evaluation index to measure the influence of the ratio of liquid to material, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com