Method for preparing shea butter by adopting subcritical propane extraction technology, shea butter and application

A technology of shea butter and extraction technology, applied in application, cosmetic preparations, edible oil/fat, etc., to achieve the effect of easy absorption by the human body, recovery and maintenance of natural elasticity, and broad prospects for development and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment is used to illustrate the method for preparing shea butter using subcritical propane extraction technology of the present invention, and the specific steps are as follows:

[0032] Step 1: Cleaning the shea nut cores, then freeze-drying, controlling the water content to 2%, and then crushing the shea nut kernels into fine powders of about 40-80 mesh with a pulverizer for future use.

[0033] Step 2: Weigh a certain amount of shea nut powder and pack it in a 120-mesh filter bag, put it into the extraction tank, and then evacuate to reduce the pressure in the extraction tank to -0.1MPa.

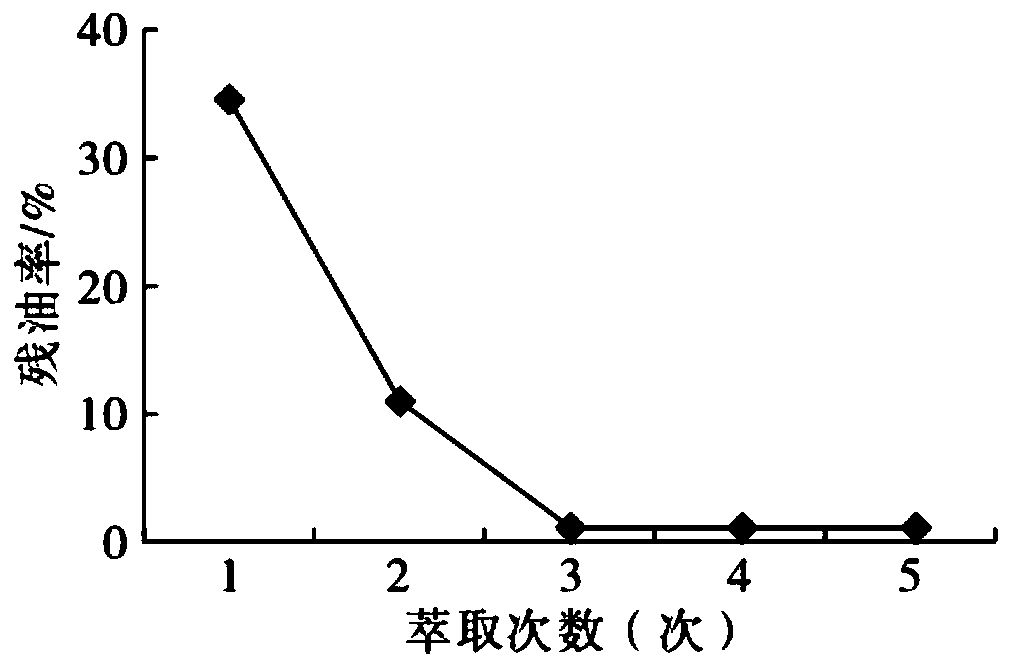

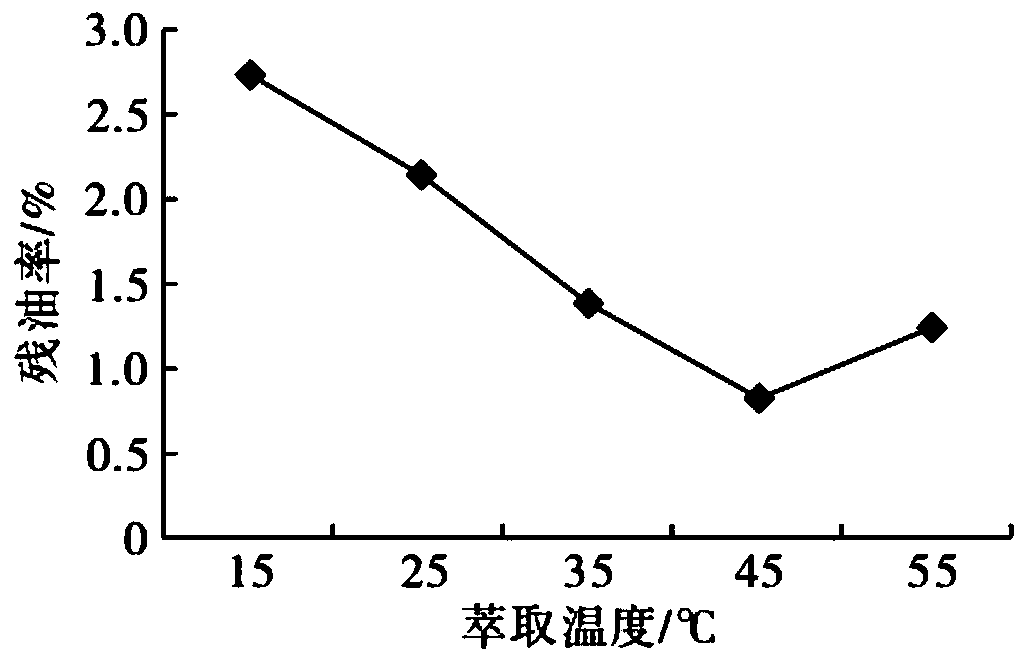

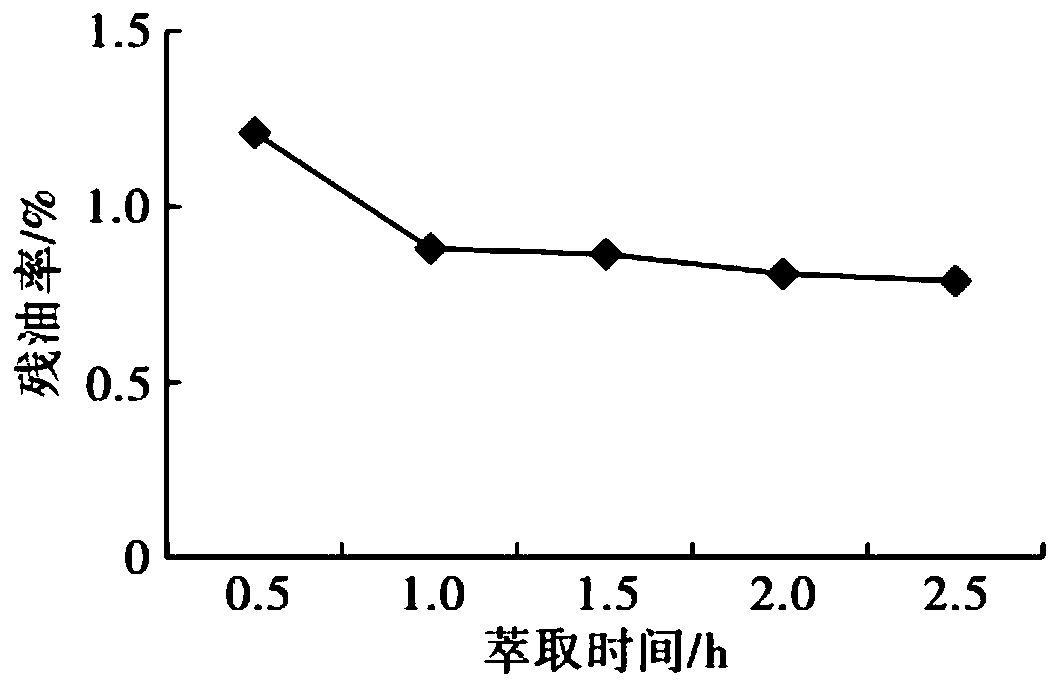

[0034] Step 3: Import the extraction solvent propane from the solvent tank into the extraction tank, and extract according to the set conditions; the set conditions include: extraction pressure 0.2MPa, extraction temperature 20°C, solid-liquid ratio 1:3, extraction times 2 times, each extraction time is 40min.

[0035] Step 4: After the extraction, use a booster pump to ...

Embodiment 2

[0038] This embodiment is used to illustrate the method for preparing shea butter using subcritical propane extraction technology of the present invention, and the specific steps are as follows:

[0039] Step 1: cleaning the shea nut cores, then freeze-drying, controlling the water content to 2-6%, and then using a pulverizer to crush the shea nut kernels into fine powders of about 40-80 mesh for later use.

[0040] Step 2: Weigh a certain amount of shea nut powder and pack it in a 120-mesh filter bag, put it into the extraction tank, and then evacuate to reduce the pressure in the extraction tank to -0.1MPa.

[0041] Step 3: Import the extraction solvent propane from the solvent tank into the extraction tank, and extract according to the set conditions; the set conditions include: extraction pressure 0.5MPa, extraction temperature 45°C, solid-liquid ratio 1:5, extraction times 3 times, each extraction time is 60min.

[0042] Step 4: After the extraction, use a booster pump t...

Embodiment 3

[0045] This embodiment is used to illustrate the method for preparing shea butter using subcritical propane extraction technology of the present invention, and the specific steps are as follows:

[0046] Step 1: Cleaning the shea nut kernels, then freeze-drying, controlling the water content to 6%, and then crushing the shea nut kernels into a fine powder of about 80 meshes with a grinder for later use.

[0047] Step 2: Weigh a certain amount of shea nut powder and pack it in a 120-mesh filter bag, put it into the extraction tank, and then evacuate to reduce the pressure in the extraction tank to -0.1MPa.

[0048]Step 3: Import the extraction solvent propane from the solvent tank into the extraction tank, and extract according to the set conditions; the set conditions include: extraction pressure 0.8MPa, extraction temperature 60°C, solid-liquid ratio 1:8, extraction times 5 times, each extraction time is 90min.

[0049] Step 4: After the extraction, use a booster pump to int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com