Anti-explosion barrel for blocking flammable and explosive hazardous chemical substances

A barrier explosion-proof, flammable and explosive technology, applied to the types of packaging items, impact-sensitive items, containers, etc., can solve problems such as high risk, rising oil drum temperature, and logistics supply can not keep up, to improve practicality performance, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

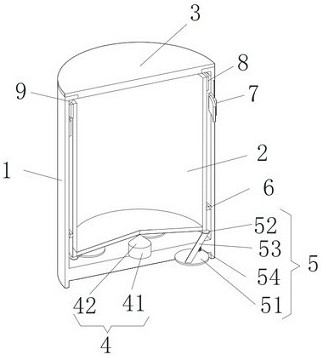

[0033] Example 1: Please refer to figure 1 and Figure 5-6 , inflammable and explosive hazardous chemicals barrier explosion-proof barrel, including outer barrel body 1, the outer barrel body 1 is the barrel body whose upper surface is not completely open, the inner barrel body 2 is arranged in the outer barrel body 1, and the outer barrel body 1 is covered with useful For the sealed barrel cover 3, a supporting device 4 is provided between the outer barrel body 1 and the inner barrel body 2, the bottom surface of the inner barrel body 2 is conical-shaped upwards, and the supporting device 4 corresponds to the raised position of the inner barrel body 2, A stabilizing device 5 is also provided between the outer barrel body 1 and the inner barrel body 2. There are four stabilizing devices 5 located at the bottom of the outer barrel body 1 at equal distances. The stabilizing device 5 includes a chassis 51 and a support plate 52. The positions corresponding to the inner bottom su...

Embodiment 2

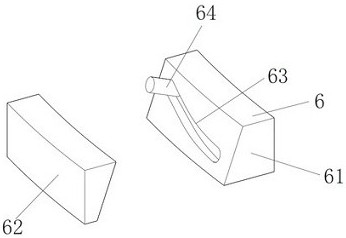

[0036] Embodiment 2: On the basis of Embodiment 1, please refer to figure 2 The force unloading device 6 includes a contact block 61 and a mounting block 62, the contact block 61 and the mounting block 62 are complementary and incomplete circular rings, and both the contact block 61 and the mounting block 62 are blocks with a trapezoidal cross-section. The block 61 is in contact with the inner barrel body 2, and the installation block 62 is fixedly connected with the side wall of the outer barrel body 1. The contact block 61 is provided with a guide chute 63, which is an arc-shaped groove provided obliquely, and guides The upper side of the chute 63 is movably clamped with a connecting column 64, and the position corresponding to the guiding chute 63 on the mounting block 62 is provided with a draw-in slot having the same size as the guiding chute 63, and the other end of the connecting column 64 is connected to the mounting block. 62 are snapped together.

Embodiment 3

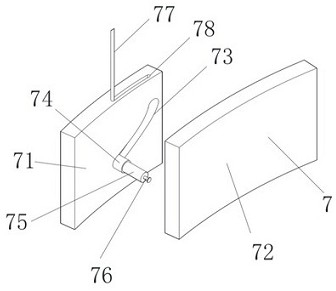

[0037] Embodiment three: on the basis of embodiment two, please refer to Figure 3-4 , the control device 7 includes a fixed plate 71 and a movable plate 72, the fixed plate 71 is an arc-shaped block whose radian is the same as that of the inner wall surface of the outer barrel body 1, and the movable plate 72 is an arc-shaped block whose radian is the same as that of the outer wall surface of the inner barrel body 2 block, the thickness of the fixed plate 71 and the movable plate 72 is adapted to the distance between the outer barrel body 1 and the inner barrel body 2, the size of the movable plate 72 is twice the size of the fixed plate 71, and the fixed plate 71 is close to the movable plate 72 Half of the area on one side of one side fits with the movable plate 72, and the vertical position of the movable plate 72 corresponds to the movable ring 8. The fixed plate 71 is provided with a guide chute 73, and the guide chute 73 is an arc that is inclined. slot, and the guide c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com