A forging method of high-performance bearing steel ball blank

A bearing steel ball, high-performance technology, applied in the field of steel ball parts forging, can solve the problems of ball billet streamline outcropping, uncontrollable flash size, etc., to optimize the streamline distribution, improve the streamline outcrop, reduce Angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

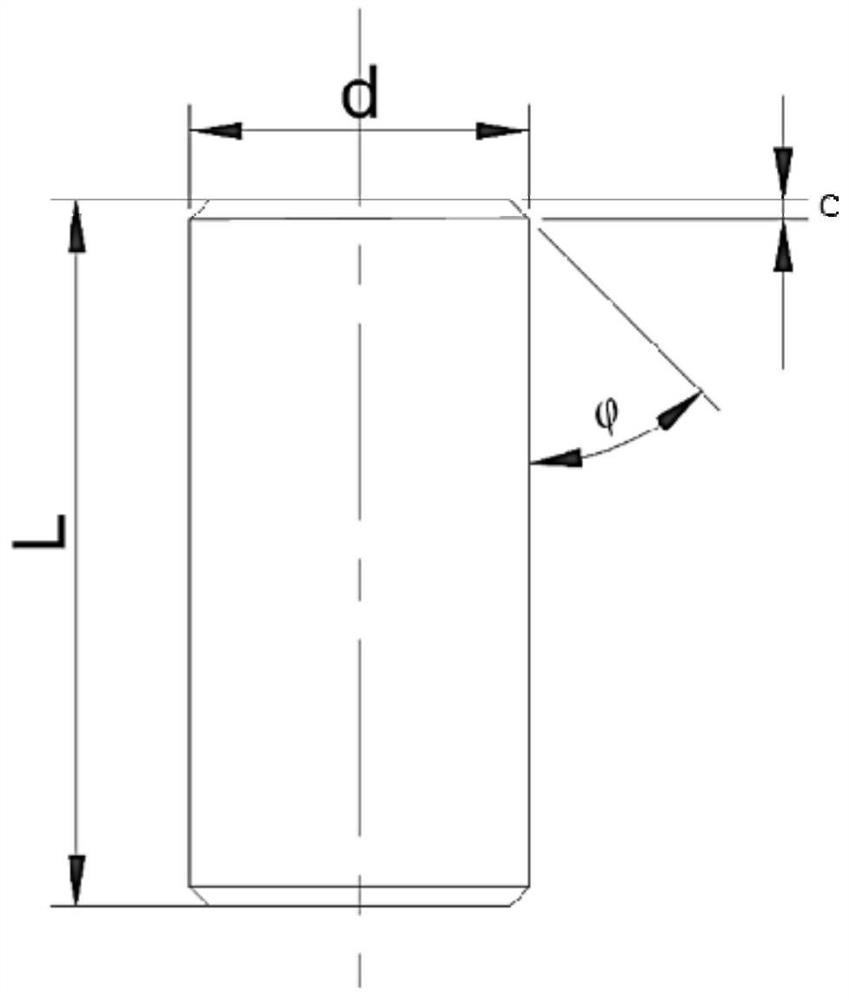

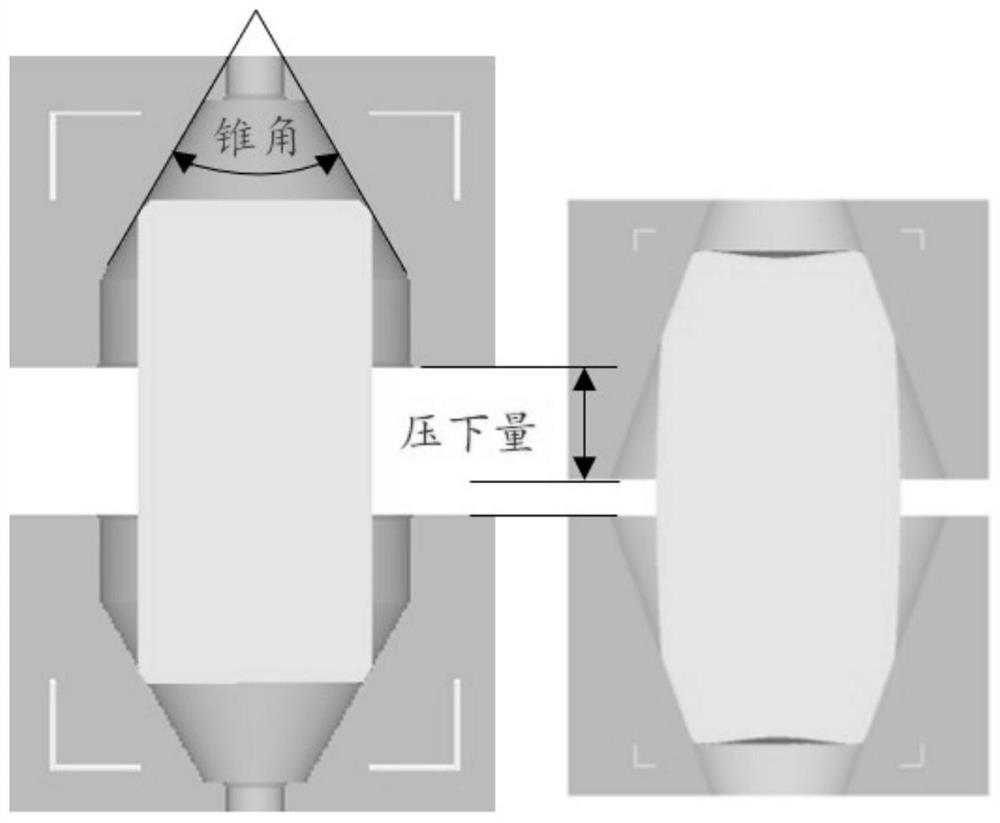

[0030] Embodiment 1: Combining Figures 1 to 7 Specifically, the forging method for a high-performance bearing steel ball blank described in this embodiment is carried out according to the following steps:

[0031] 1. Feeding:

[0032] Cut the round bar material to obtain a cylindrical material section, grind the upper and lower end faces of the cylindrical material section to ensure that the length of the material section is within the tolerance range, and then chamfer the upper and lower end faces to obtain the processed material section. The latter section is heated to 900°C to 1100°C and kept warm to obtain the heated section;

[0033] The chamfer angle is half of the taper angle in the conical pre-forging die cavity described in step 2; the quality of the processed material section is equal to the quality of the bearing steel ball blank prepared in step 3;

[0034] 2. Pre-forging:

[0035] Before pre-forging, apply lubricant inside the cavity of the conical pre-forging...

specific Embodiment approach 2

[0049] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the upper and lower end faces of the cylindrical material section are ground, so that the length tolerance between the upper and lower end faces is within 0.1 mm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0050] Embodiment 3: The difference between this embodiment and Embodiment 1 or Embodiment 2 is that the material of the round bar described in step 1 is bearing steel 8Cr4Mo4V. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com