A calibration device for the production of processed auto parts

A technology for calibrating devices and auto parts, applied in the field of parts processing, can solve the problems of wasting time, the parts are difficult to grasp the calibration angle, etc., and achieve the effect of rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

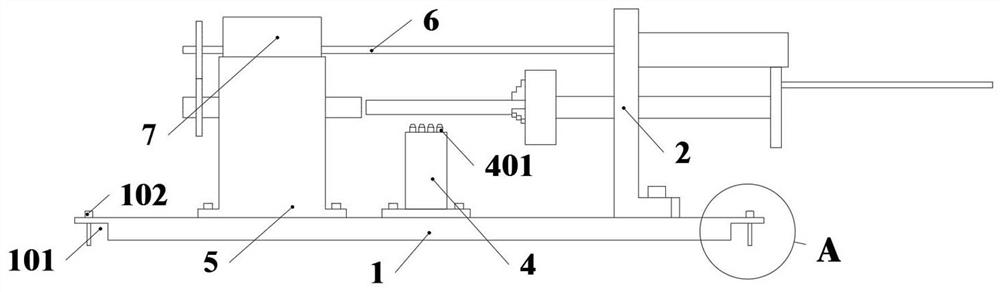

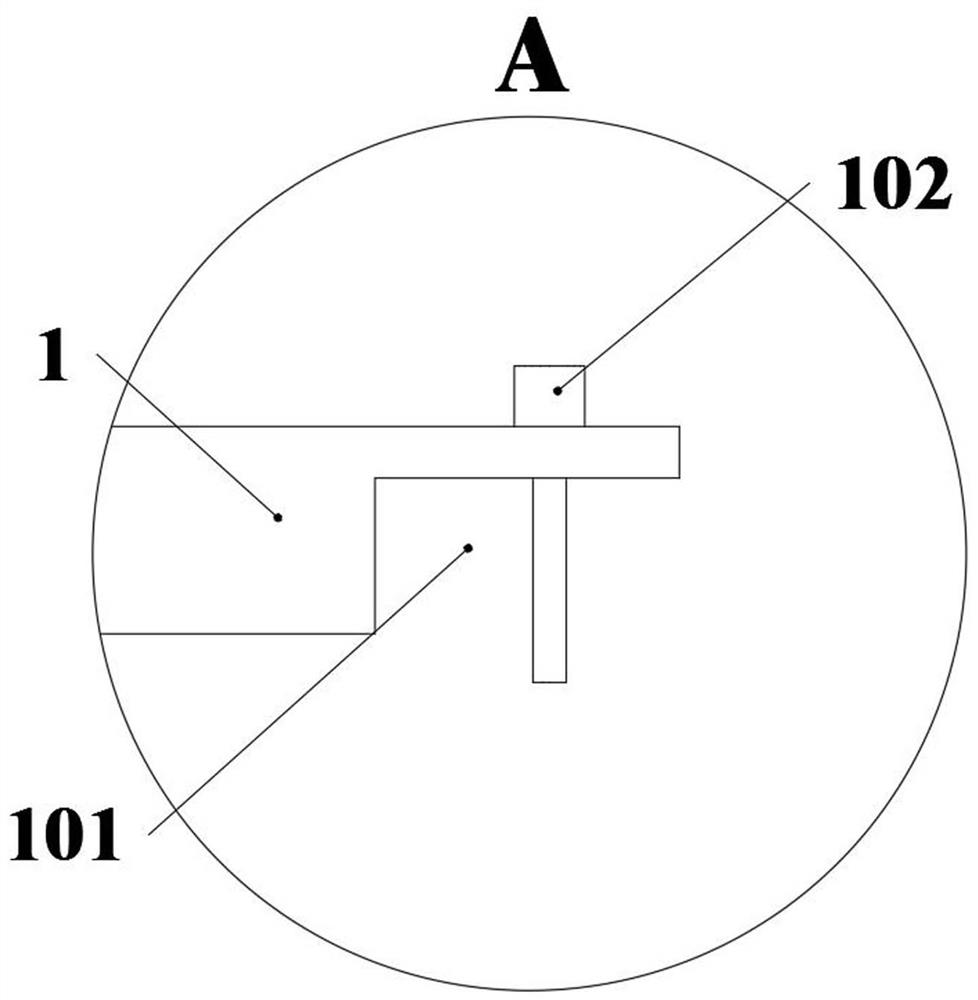

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036]The present invention provides a calibration device for the production of processed auto parts, comprising a base 1, a driving part 2, a calibration part 5, a transmission part 6 and an auxiliary part 7; the base 1 is installed on a workbench; The threaded rod 202, the handle 203 and the clamp 204 are composed, and the seat body 201 is fixedly connected to the base 1 by bolts, and the parts 3 are clamped on the clamp 204; the heating seat 4 is fixedly connected to the base 1 by bolts; the correction part 5 is composed of a box body 501, correction seat 502, groove 503, impeller A504 and friction wheel A505, and the box body 501 is fixedly connected to the base 1 by bolts; the box body 501 is filled with water, and the water contacts the correction seat 502, thereby The rapid cooling of the correction seat 502 and the parts 3 in the correction seat 502 can be realized; there are two impellers A504, and the two imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com