Multistage screening device for color concentrate processing

A screening device and color masterbatch technology, which is applied in the direction of filtering, packaging, solid separation, etc., can solve the problems of color masterbatch splashing, affecting the screening efficiency, and easy leakage of the screen, so as to save the use of space and avoid shocks. The effect of hitting deformation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

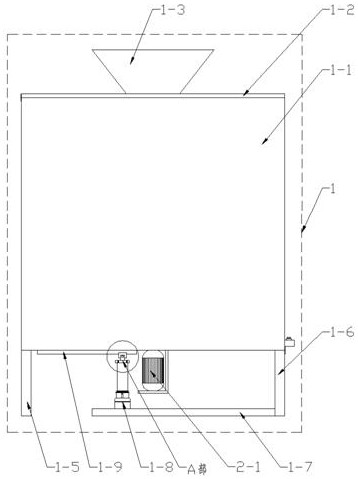

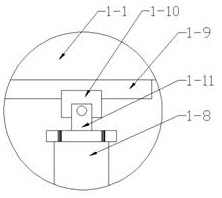

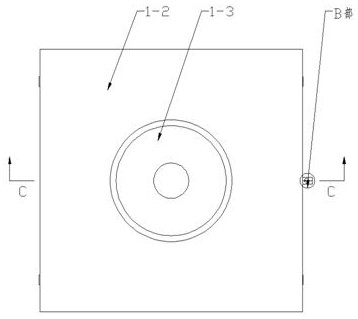

[0032] see as Figure 1 to Figure 9As shown, the technical solution adopted in this specific embodiment is: it includes a screening box body 1 and a screening mechanism 2; the screening box body 1 includes a box body 1-1, a cover body 1-2, a feed hopper 1-3, fixed support plate 1-5, movable support plate 1-6, installation plate 1-7, electric push rod 1-8, slide rail 1-9, No. 1 slider 1-10, connecting plate 1-11 , discharge pipe 1-12, circular plate 1-13, screw rod 1-14, nut 1-15, rotating rod 1-16 and linear marking layer 1-17; the upper end of box body 1-1 is hinged with cover body 1 -2; The cover body 1-2 is provided with a feed hopper 1-3 through bolts, and the lower end of the feed hopper 1-3 is fixed with a ring baffle 1-4 by bolts, and the ring baffle 1-4 prevents color masterbatch Flying to improve the efficiency of sieving; the left side of the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com