Reciprocating motion extrusion type strip seedbed construction unit

A reciprocating, extrusion-type technology, applied to agricultural machinery and implements, applications, plows, etc., can solve the problems of poor quality of strip seed beds, poor quality of seed beds, and large power consumption, etc., to achieve less power consumption in operations, High operating efficiency, avoiding lost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

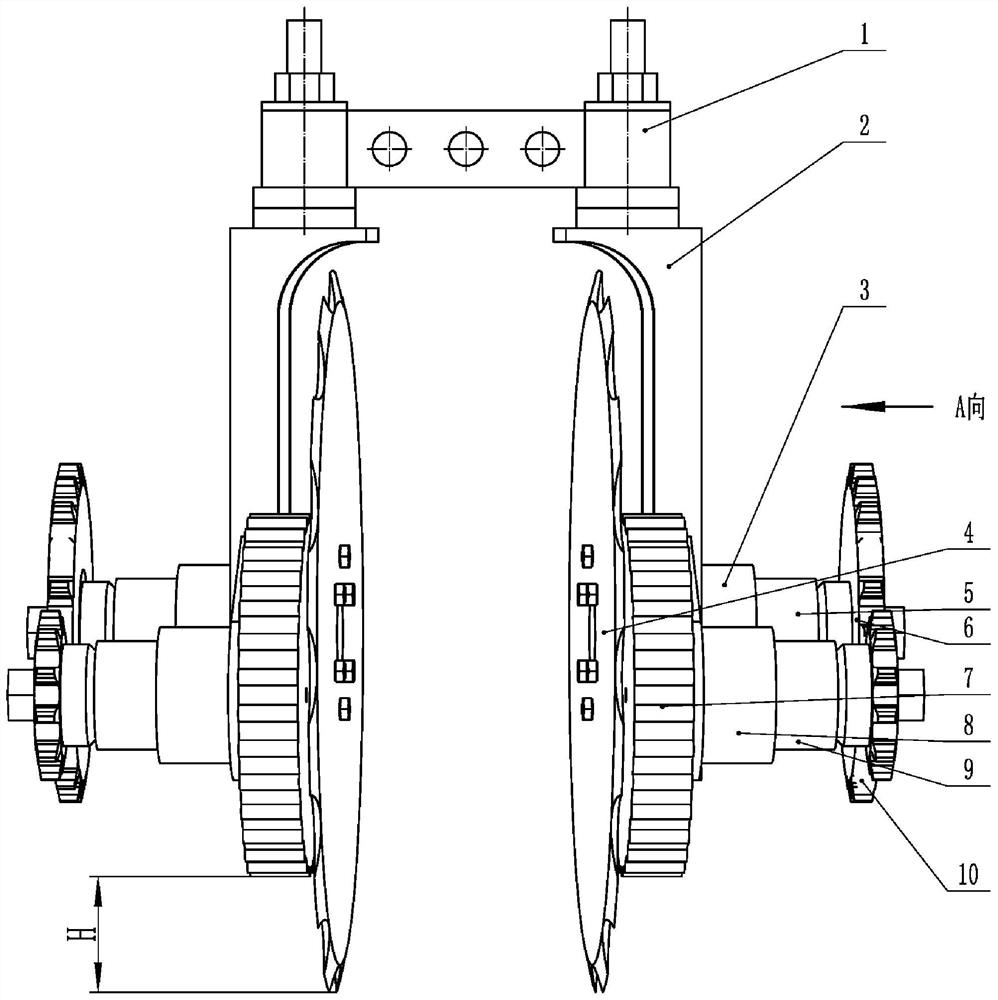

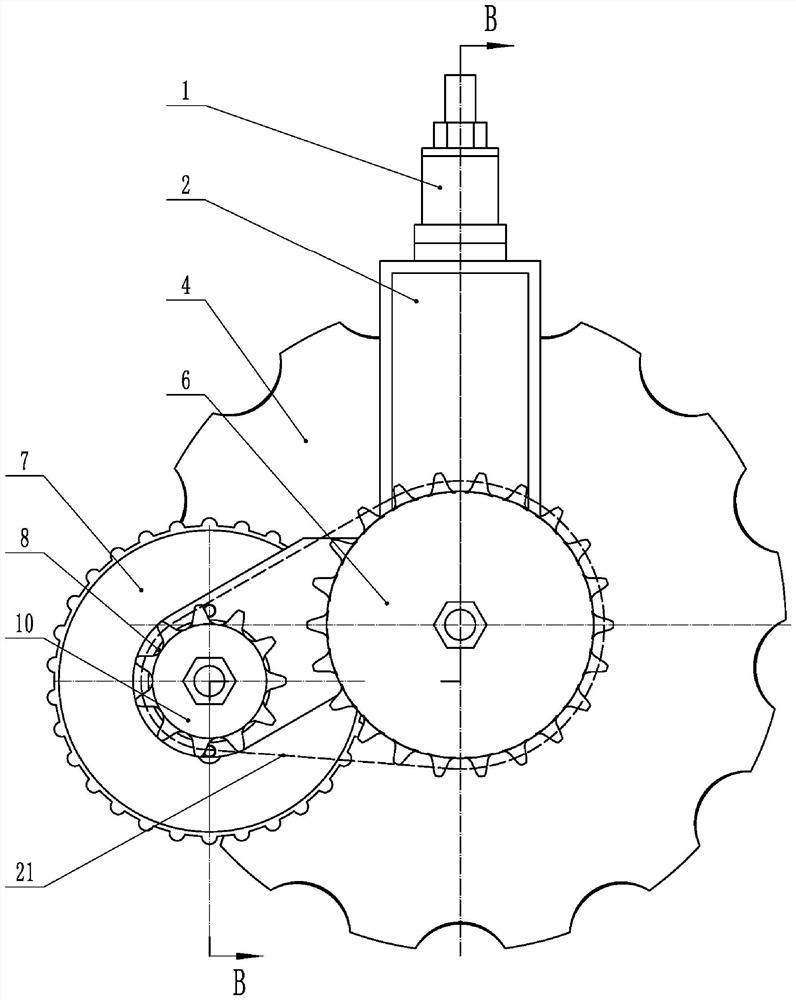

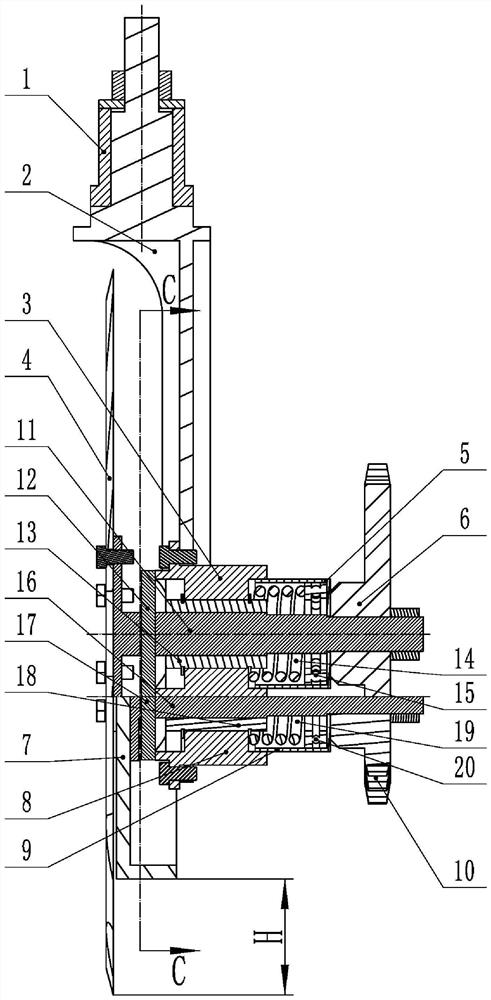

[0012] The present invention has been described in detail below with reference to the accompanying drawings. A reciprocating extruded strip-band bed construction monomer, mutually symmetrical and stimulated on the connecting frame 1, a mounting hanging arm 2, a fixed end surface cam A3 in the upper shaft line of the hanging arm 2 And the end surface cam B8; fixed self-lubricating sleeve A13 in the central hole of the end surface cam A3, a knife shaft 11 with a rod A12 radially positioned, circumferential rotation, axial movable insert mounting In the self-lubricating sleeve A13 sleeve, the sip pole A12 is in contact with the end surface cam A3, and at the knife shaft 11 and located at the outer portion of the self-lubricating sleeve A13 through the planar thrust bearing A15 fixed spring seat A5, The pressure spring A14 is set on the knife shaft 11, and is located in the spring seat A5, and the inner and outer end faces of the pressure spring A14 are in contact with the end surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com