Online monitoring system and method for concentration of sulfite ions in desulfurization slurry

A technology of sulfite and desulfurization slurry, which is applied in the direction of liquid/fluid solid measurement, measuring devices, liquid level indicators, etc., can solve the problems of system and method scaling, small particle size of calcium sulfite, and reduced desulfurization efficiency. Achieve the effect of improving precise control ability, wide range of types and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

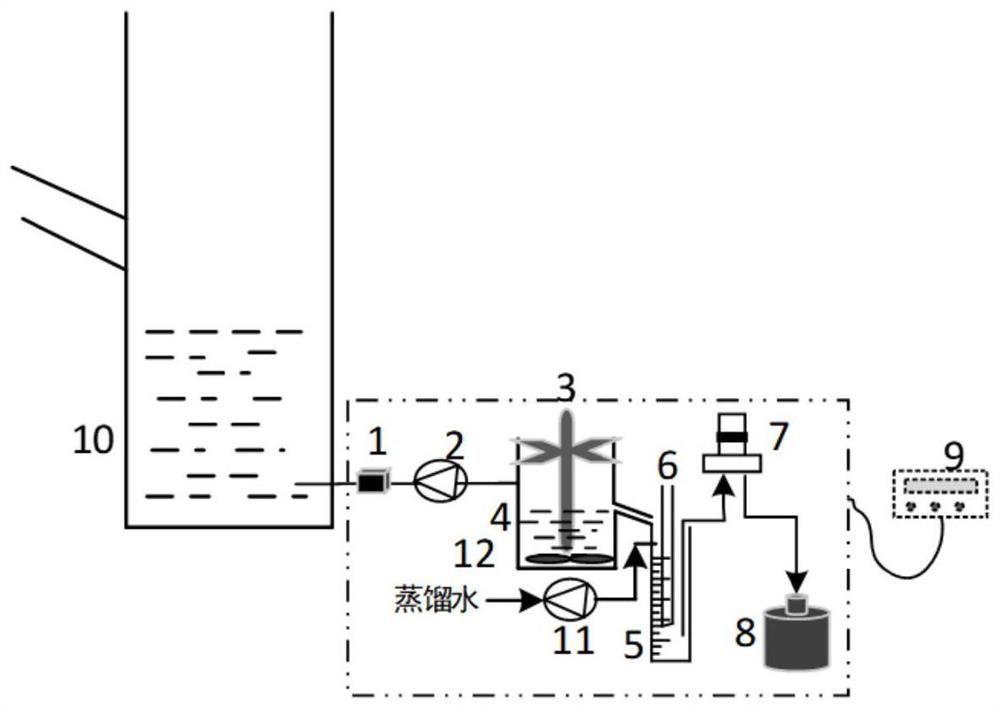

[0035] A kind of online monitoring system of sulfite ion concentration in the desulfurization slurry of the present invention, such as figure 1 As shown, it includes filter 1, liquid suction pump 2, sulfite ion electrode 3, liquid reservoir 4, scale liquid collection pipe 5, liquid level gauge 6, electromagnetic pulse pump 7, waste liquid bucket 8, control system 9, Desulfurization slurry tower 10, liquid injection pump 11 and stirring device 12;

[0036] The slurry pool of the desulfurization slurry tower 10 is sequentially connected with a filter 1, a liquid pump 2, a liquid reservoir 4, a graduated liquid collection pipe 5, an electromagnetic pulse pump 7 and a waste liquid bucket 8; the liquid reservoir 4 A sulfite ion electrode 3 is set inside, and a liquid overflow port is set on the side wall; the scale liquid collection pipe 5 is connected to the liquid overflow port, and a liquid level gauge 6 and a stirring device 12 are arranged in it, and a useful Injecting liquid...

Embodiment 2

[0056] Adopt concentration in the present embodiment and be the sodium sulfite solution of 28.82g / L in such as figure 1 The above-mentioned system is implemented as an example, and the results are as follows.

[0057] The sodium sulfite solution (sulfite ion concentration is 18.30g / L) that preparation concentration is 28.82g / L in laboratory, adopts the method described in the present invention to carry out on-line test, records the sulfite ion concentration in solution and is 18.46 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com