Ionic antibacterial anti-mite heat storage fabric and processing technology thereof

An anti-mite and fabric technology, applied in the direction of plant fibers, animal fibers, textiles and paper making, can solve problems such as odor, disease, and human injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Prepare active ingredient, this active ingredient is made by following steps:

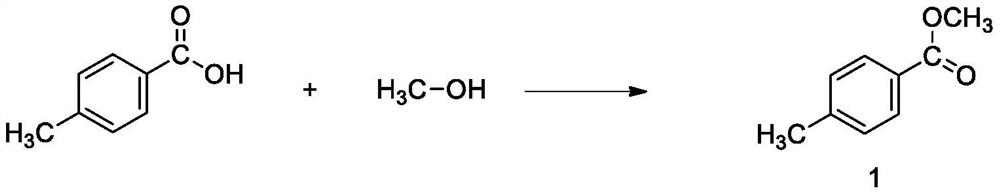

[0042] Step S1: Add p-toluic acid and methanol into the flask, then slowly dropwise add sulfuric acid solution with a mass fraction of 70%, reflux for 12 hours, then distill off excess methanol solution under reduced pressure, then add distilled water, use dichloromethane Extracted 3 times, dried over anhydrous magnesium sulfate, and distilled under reduced pressure to obtain intermediate 1; the dosage ratio of p-toluic acid, methanol, and sulfuric acid solution was 0.1mol: 80mL: 2mL;

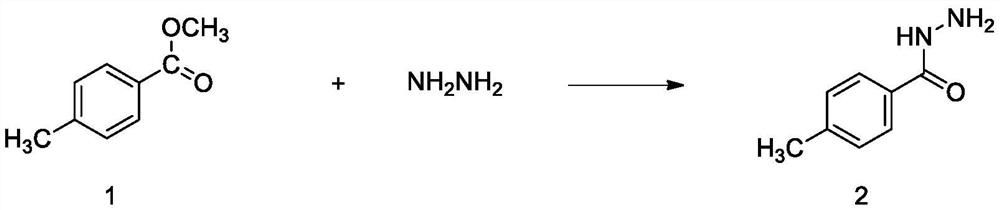

[0043] Step S2: add intermediate 1 to hydrazine hydrate with a mass fraction of 80%, stir and react at room temperature for 11 hours, and dry to obtain intermediate 2 after the reaction; the ratio of intermediate 1 and hydrazine hydrate is 0.08mol : 30mL;

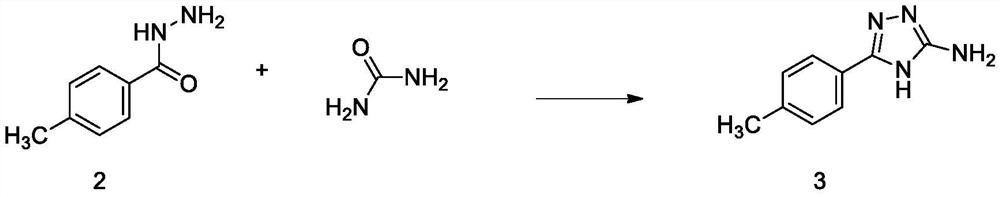

[0044] Step S3: Add intermediate 2, carbonamide and deionized water into the flask, and reflux reaction at a temperature of 100° C. for 8 hours to obtain...

Embodiment 2

[0049] Prepare active ingredient, this active ingredient is made by following steps:

[0050] Step S1: Add p-toluic acid and methanol into the flask, then slowly dropwise add sulfuric acid solution with a mass fraction of 70%, reflux for 12 hours, then distill off excess methanol solution under reduced pressure, then add distilled water, use dichloromethane Extracted 3 times, dried over anhydrous magnesium sulfate, and distilled under reduced pressure to obtain intermediate 1; the dosage ratio of p-toluic acid, methanol, and sulfuric acid solution was 0.1mol: 80mL: 2mL;

[0051] Step S2: add intermediate 1 to hydrazine hydrate with a mass fraction of 80%, stir and react at room temperature for 12 hours, and dry to obtain intermediate 2 after the reaction; the ratio of intermediate 1 and hydrazine hydrate is 0.08mol : 30mL;

[0052] Step S3: Add intermediate 2, carbonamide and deionized water into the flask, and reflux reaction at a temperature of 100° C. for 9 hours to obtain...

Embodiment 3

[0057] Prepare active ingredient, this active ingredient is made by following steps:

[0058] Step S1: Add p-toluic acid and methanol into the flask, then slowly dropwise add sulfuric acid solution with a mass fraction of 70%, reflux for 12 hours, then distill off excess methanol solution under reduced pressure, then add distilled water, use dichloromethane Extracted 3 times, dried over anhydrous magnesium sulfate, and distilled under reduced pressure to obtain intermediate 1; the dosage ratio of p-toluic acid, methanol, and sulfuric acid solution was 0.1mol: 80mL: 2mL;

[0059] Step S2: add intermediate 1 to hydrazine hydrate with a mass fraction of 80%, stir and react at room temperature for 13 hours, and dry to obtain intermediate 2 after the reaction; the ratio of intermediate 1 and hydrazine hydrate is 0.08mol : 30mL;

[0060] Step S3: Add intermediate 2, carbonamide and deionized water into the flask, and reflux at a temperature of 100° C. for 10 h to obtain intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com