A realization method of fabric automatic detection and tension automatic adjustment of flat knitting machine pulling device

A pulling device and automatic adjustment technology, applied in textiles and papermaking, optical device exploration, knitting, etc., can solve problems such as change and complexity, and achieve the effects of avoiding human errors, high degree of automation, and reducing manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

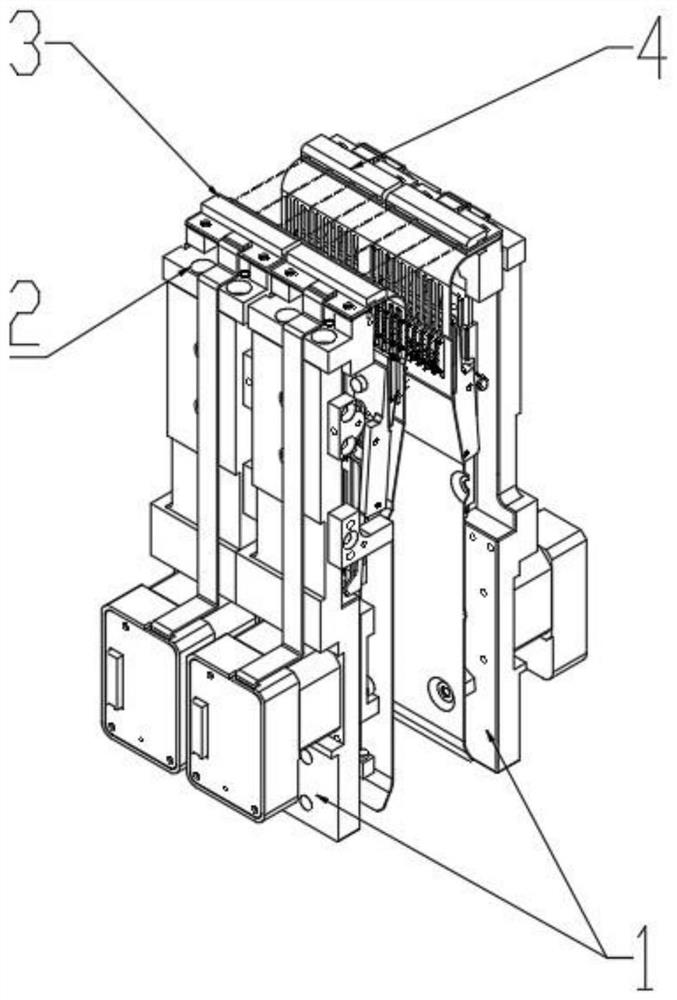

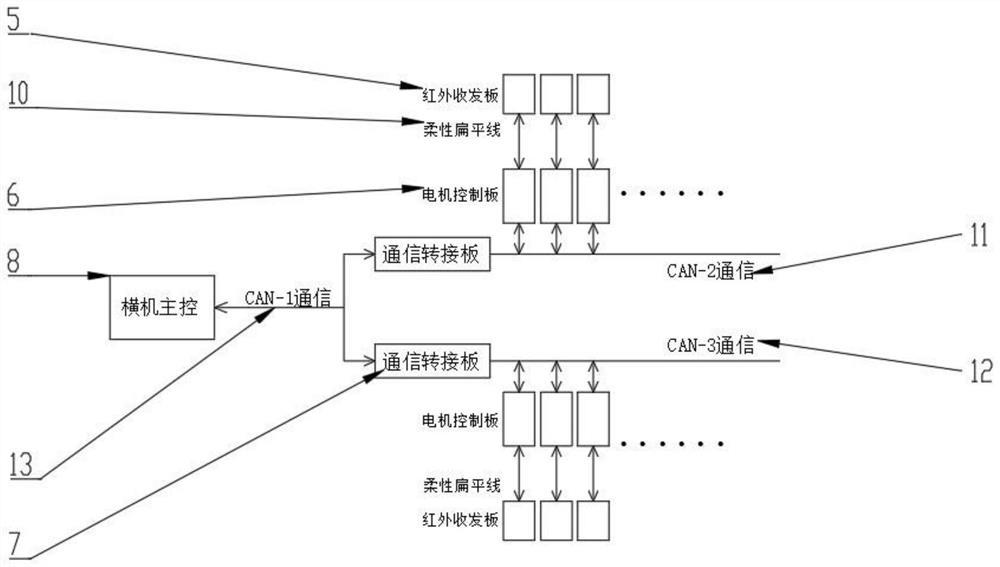

[0024] see Figure 1-3 , a method for realizing automatic fabric detection and tension automatic adjustment of a flat knitting machine drawing device, which uses an infrared device to detect the fabric width between the flat knitting machine drawing device 1, and then automatically adjusts the layer mode and adjusts the tension through algorithm processing.

[0025] The implementation method is as follows:

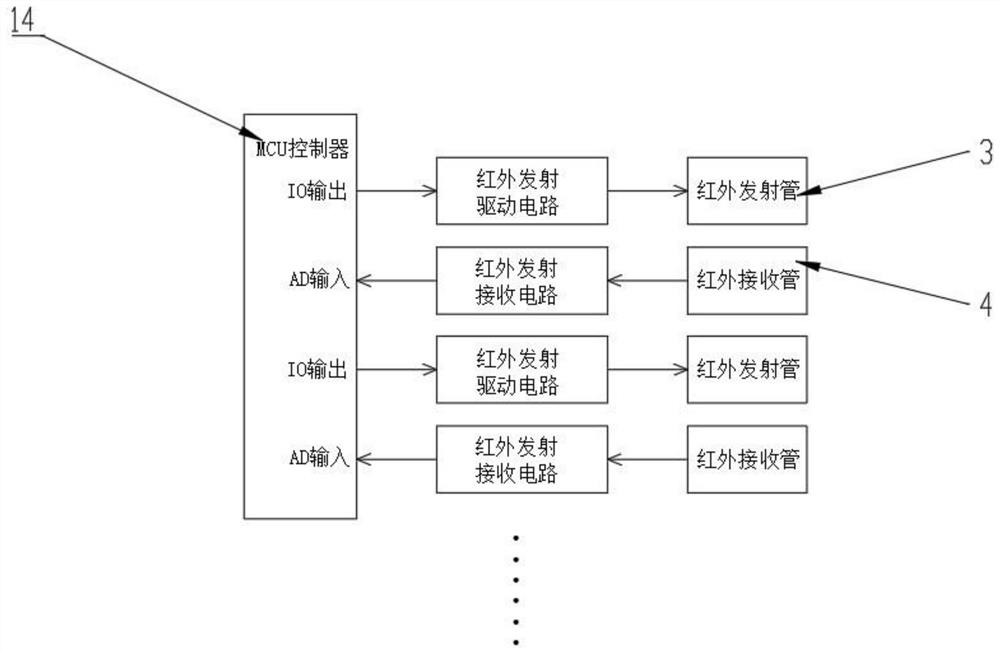

[0026] Step 1. Based on the symmetry of the flat knitting machine pulling devices on both sides, a row of rakes 2 on one side of the flat knitting machine pulling device 1 is provided with infrared emission tubes 3, and the flat knitting machine pulling device on the other side The upper row of rakes 2 are all equipped with infrared receiving tubes 4 corresponding to the infrared emitting tubes 3, and the existence of fabric between the flat knitting machine pulling devices 1 on both sides prevents the receiving of the infrared receiving tubes 4, and the horizontal knittin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap