Waterproof stone-like coating and preparation method thereof

A technology of real stone paint and processing method, applied in the field of building decoration materials, can solve the problems of affecting the decorative effect of real stone paint, affecting the effect of building use, affecting the quality of the project, etc., so as to enhance the water resistance and anti-contamination ability, and achieve the effect of imitating stone. The best effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

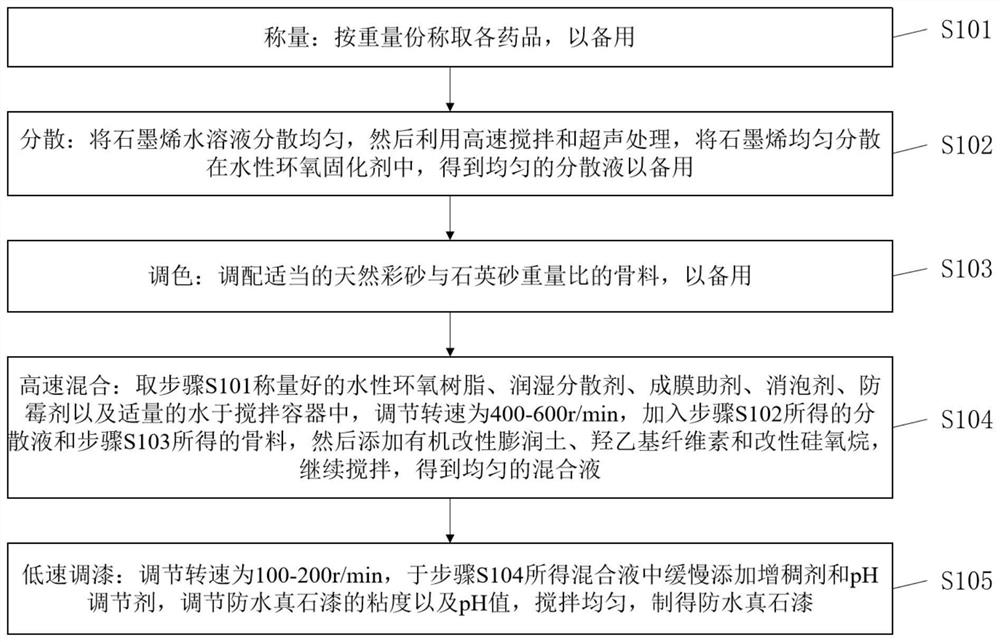

Method used

Image

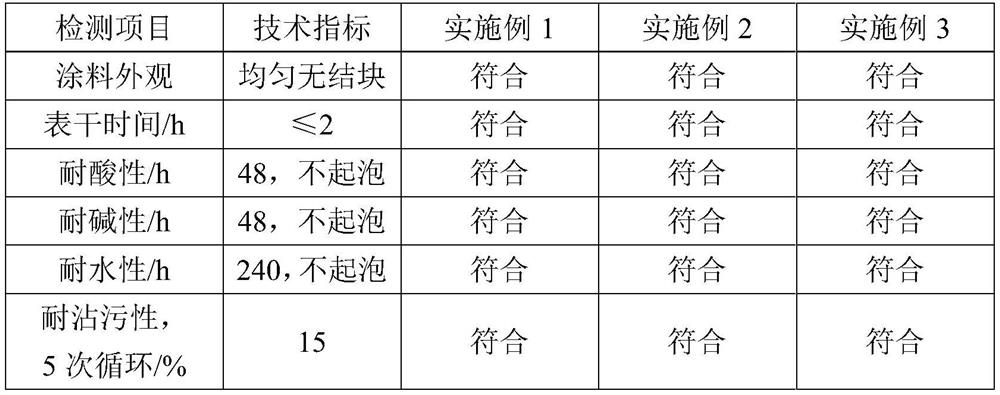

Examples

specific Embodiment 1

[0027] In the present embodiment, by weight, the specific formula is:

[0028] Waterborne epoxy resin 15 copies water-based curing agent 3 copies Graphene 5 copies aggregate 80 copies Organic modified bentonite 15 copies Hydroxyethyl cellulose 10 copies Modified siloxane 0.5 parts Wetting and dispersing agent 0.5 parts Coalescent 1 copy Defoamer 0.5 parts thickener 0.5 parts antifungal agent 0.5 parts pH regulator 0.5 parts water Appropriate amount

[0029] Among them, the aggregate is a mixture of natural colored sand and quartz sand, the weight ratio of natural colored sand and quartz sand is 1:1, and the particle size of natural colored sand is 40 mesh, and the particle size of quartz sand is 80 mesh; It is a polycarboxylic acid-alkyl ammonium salt; the film-forming aid is ethylene glycol; the defoamer is selected from organosilicon modified defoamers; the thickener is ...

specific Embodiment 2

[0037] In the present embodiment, by weight, the specific formula is:

[0038] Waterborne epoxy resin 35 copies water-based curing agent 15 copies Graphene 18 copies aggregate 120 copies Organic modified bentonite 20 copies Hydroxyethyl cellulose 25 copies Modified siloxane 2 copies Wetting and dispersing agent 1.5 servings Coalescent 4 parts Defoamer 0.8 parts thickener 1.2 parts antifungal agent 1.5 servings pH regulator 3 copies water Appropriate amount

[0039] Among them, the aggregate is a mixture of natural colored sand and quartz sand, the weight ratio of natural colored sand and quartz sand is 3:2, and the particle size of natural colored sand is 80 mesh, and the particle size of quartz sand is 120 mesh; It is an unsaturated fatty acid polyamine amide; the film-forming aid is lauryl alcohol ester film-forming aid; the defoamer is selected from mineral oil modified...

specific Embodiment 3

[0047] In the present embodiment, by weight, the specific formula is:

[0048] Waterborne epoxy resin 25 copies water-based curing agent 10 copies Graphene 12 copies aggregate 100 copies Organic modified bentonite 18 copies Hydroxyethyl cellulose 23 copies Modified siloxane 1.5 servings Wetting and dispersing agent 0.8 parts Coalescent 2 copies Defoamer 0.6 parts thickener 0.8 parts antifungal agent 1.0 copies pH regulator 1.5 servings water Appropriate amount

[0049] Among them, the aggregate is a mixture of natural colored sand and quartz sand, the weight ratio of natural colored sand and quartz sand is 2:1, and the particle size of natural colored sand is 60 mesh, and the particle size of quartz sand is 100 mesh; It is an unsaturated fatty acid polyamine amide; the film-forming aid is ethylene glycol; the defoamer is selected from polyether modified defoamers; the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com