Three-dimensional electrode reaction device and method for removing COD in wastewater

A reaction device and three-dimensional electrode technology, applied in chemical instruments and methods, water/sewage treatment, light water/sewage treatment, etc., can solve problems such as low removal efficiency, and achieve short treatment time, efficient removal, and improved utilization. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

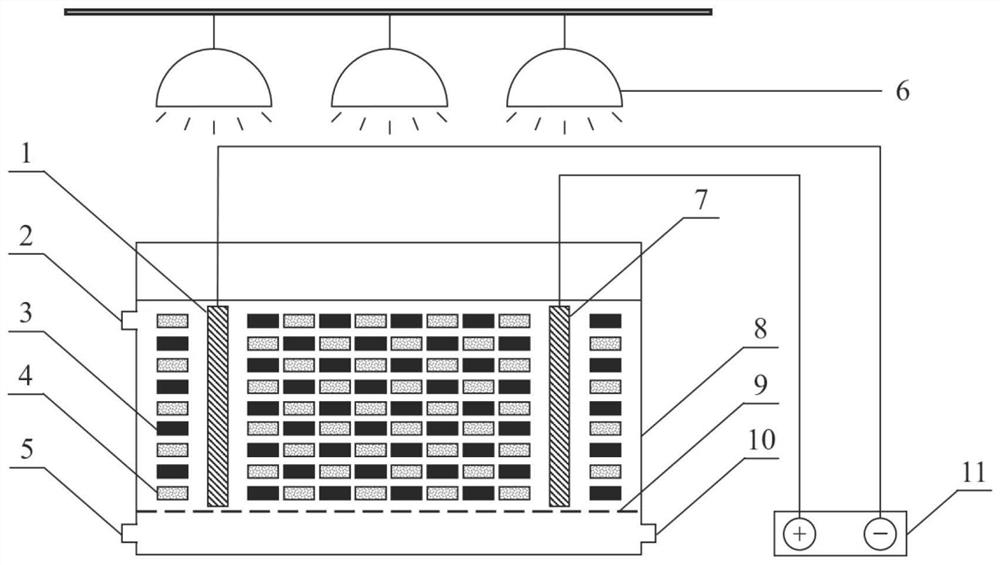

[0033] see figure 1 , the present embodiment provides a three-dimensional electrode reaction device, which includes a tank body 8, the tank body 8 is used to place various components for performing electrochemical reactions and photocatalytic reactions, and provides a reaction place for electrochemical reactions and photocatalytic reactions. In the embodiment of the present invention, the tank body 8 is a rectangular parallelepiped structure, and it can be understood that other geometric structures in the prior art can also be used.

[0034] The tank body 8 is placed on the ground or on the platform, with the side of the tank body 8 touching the ground or close to the ground as the bottom, and the side opposite to the bottom as the top, which can be a closed structure or an open structure.

[0035] The liquid inlet 2 and the liquid outlet 5 are arranged on the tank body 8, the liquid inlet 2 and the liquid outlet 5 are located on the side wall of the tank body 8, and the two a...

Embodiment 2

[0045] The embodiment of the present invention provides a method for removing COD in wastewater, using the three-dimensional electrode reaction device in embodiment 1.

[0046] Specifically, the wastewater is taken from industrial wastewater produced by a refinery, and its main characteristics are: the COD content is 3402mg / L.

[0047] The waste water is injected into the tank body from the liquid inlet, and an anode plate and a cathode plate connected to the positive pole and the negative pole of the DC power supply are respectively placed on both sides of the tank body.

[0048] The anode plate is made of graphite, the cathode plate is made of stainless steel, the distance between the anode plate and the cathode plate is 8cm, and the voltage of the DC power supply is 20V. Turn on the light source, and the light source is a high-pressure mercury lamp.

[0049] The particle electrode 3 is columnar activated carbon with a diameter of 5 mm and a length of 10 mm. The photocatal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com