Automatic roll changing machine for plastic film

A plastic film, automatic technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of low processing efficiency, reduced production efficiency, high production cost, etc., and achieve the effect of automatic roll change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

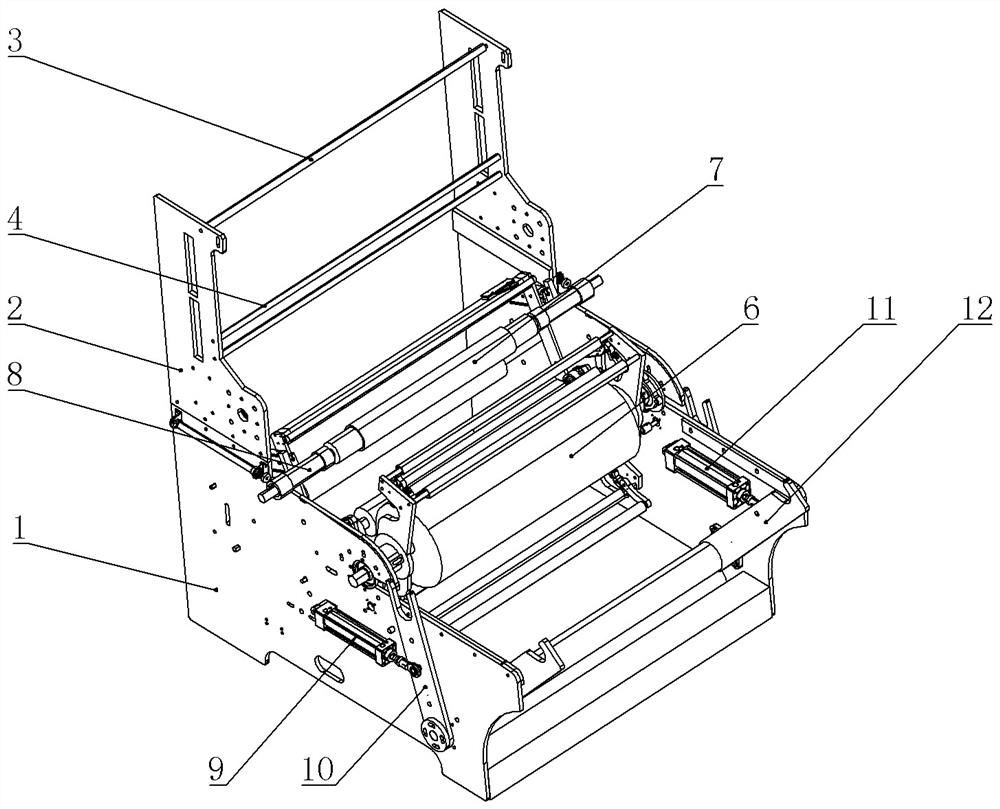

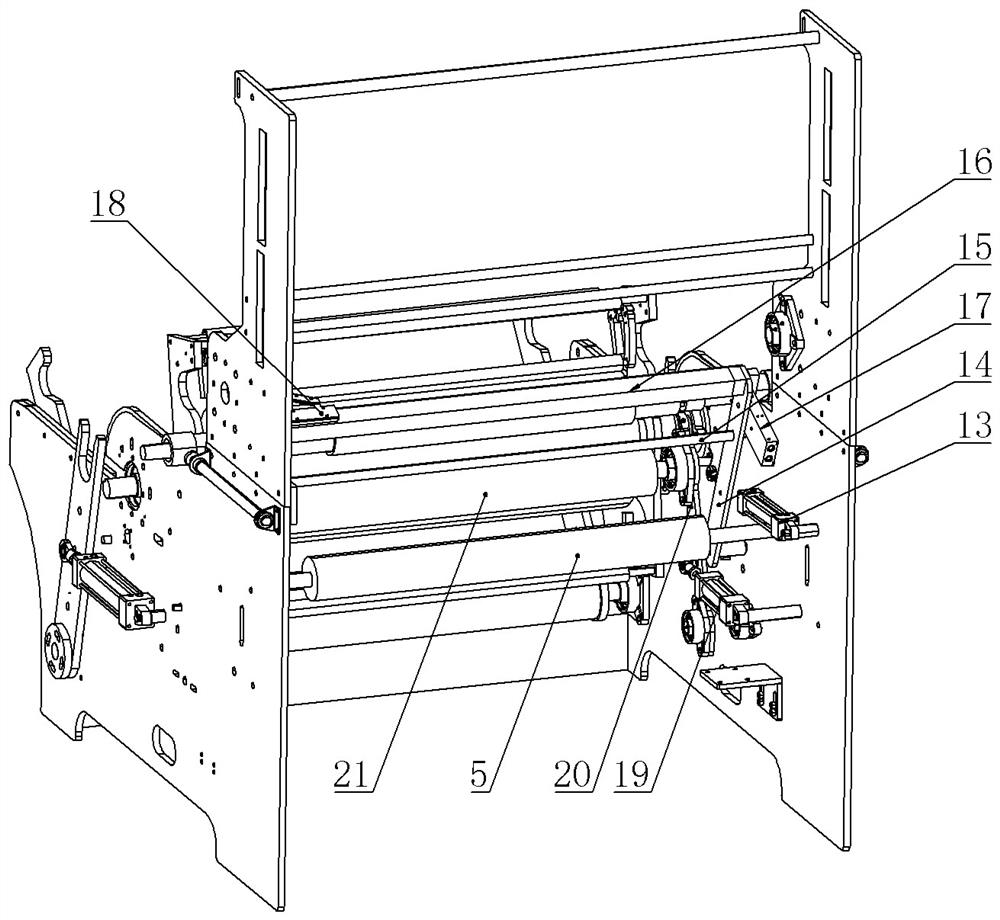

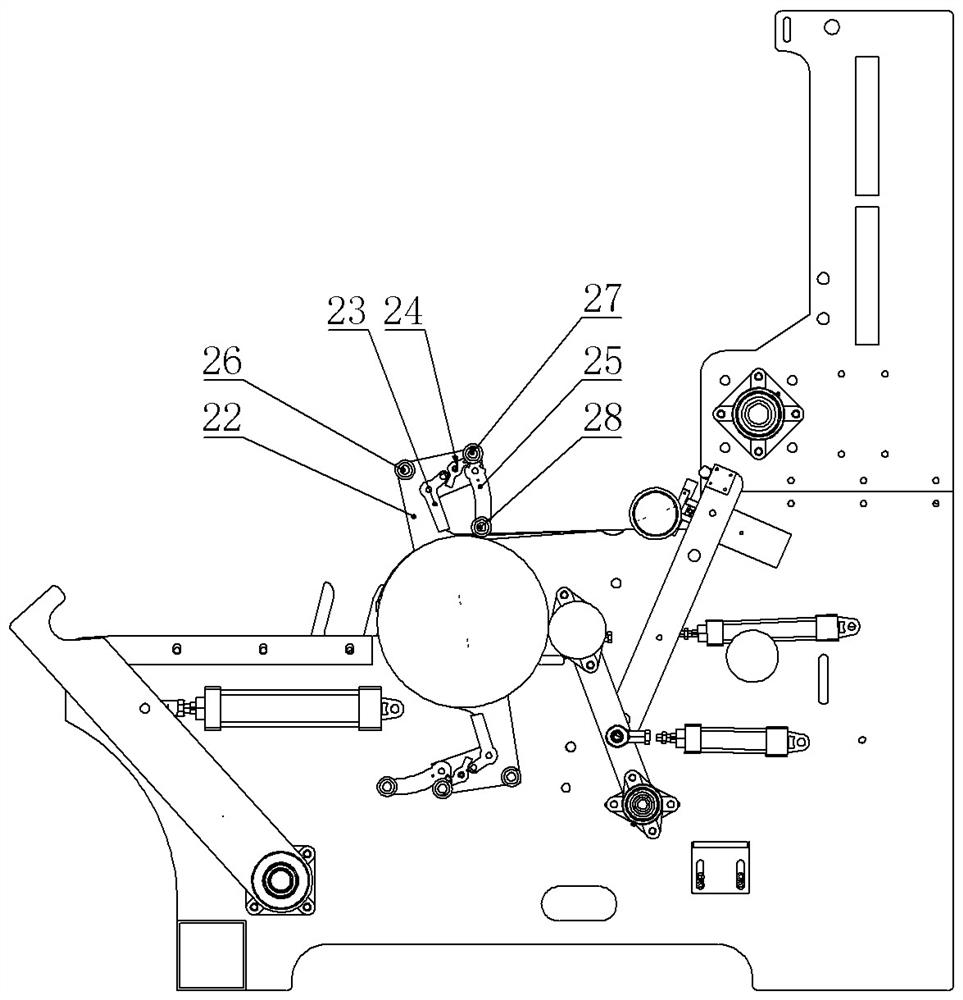

[0025] Specific implementation method: combined Figure 1-8As shown, it includes a symmetrically arranged side plate 1, a link plate 2 is provided on one side of the side plate 1, a feeding rod 3 is provided on the top of the link plate 2, and a planer bar 4 is provided on the bottom of the link plate 2. A flattening roller 5 is arranged between them, and it is characterized in that: a cutter assembly, a press arm assembly, a material preparation assembly, a turntable assembly, a press roll assembly and a roll arm assembly are sequentially arranged between the side plates 1 from back to front; The rotating shaft of the transmission roller 6 is connected to the middle position inside the side plate 1; the material preparation assembly includes a paper roll 7 and a sleeve 8; the sleeve 8 is fixed to the inner wall of the side plate 1 by bolts, and the paper roll 7 is placed in the sleeve 8, the rolling assembly includes a third cylinder 9 and a pressing arm 10; the third cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com