Single-wing labyrinth drip irrigation belt automatic winding machine

A drip irrigation tape and labyrinth technology, which is applied in the field of single-wing labyrinth drip irrigation tape automatic winding machine, can solve the problems of insufficient curling of drip irrigation tape, high labor intensity of workers, and low production efficiency, so as to reduce labor costs and improve automation Performance, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

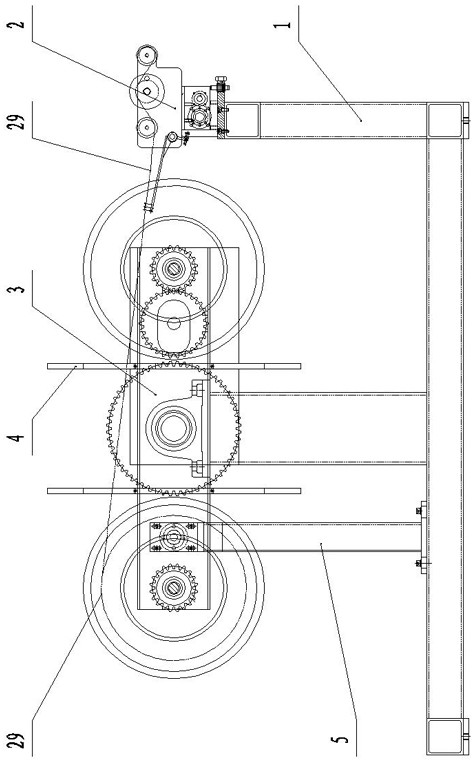

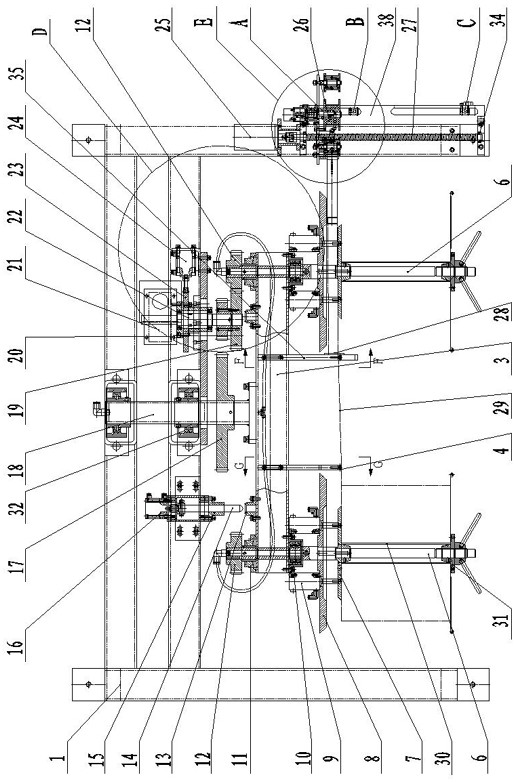

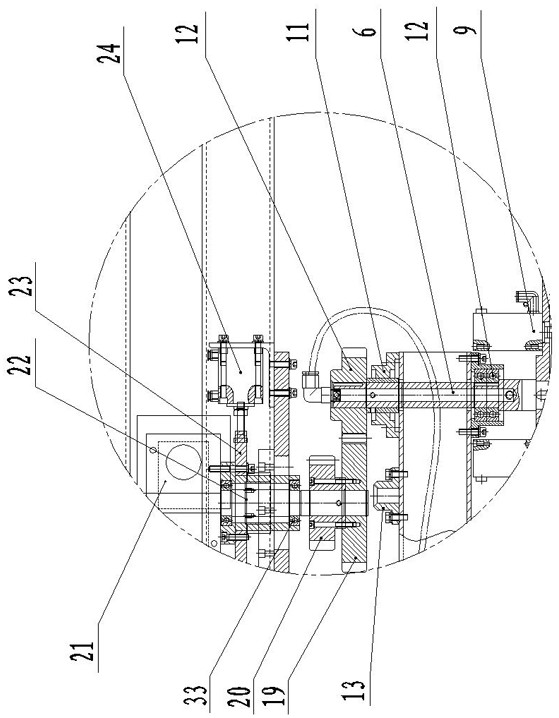

[0029] like figure 1 , 2 As shown in , 4, a single-wing labyrinth drip irrigation belt automatic rewinding machine consists of a frame 1, and a wiring mechanism 2, a rotating arm mechanism, a transmission mechanism, a coiling mechanism, and a clamping mechanism installed on the frame 1. It is composed of a positioning mechanism, the frame 1 is welded by angle steel, the cable arrangement 2 is composed of a cable bracket 26, a servo motor 25 and a ball screw 27, the upper end of the ball screw 27 is connected with the output end of the servo motor 25, and the lower end The third bearing seat 34 is fixed on the frame 1. A fixing plate 38 is provided on the left side of the ball screw 27. The fixing plate 38 is directly welded on the frame 1. The fixing plate 38 is provided with an entrainment position from the back to the front. A. The starting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com