Garbage can lifting device with weighing function

A trash can and weighing technology, applied in the directions of garbage storage, transportation and packaging, can solve the problem of inaccurate weighing of trash cans, and achieve the effect of avoiding overturning, saving space and cost, and reducing the stroke of the top cylinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

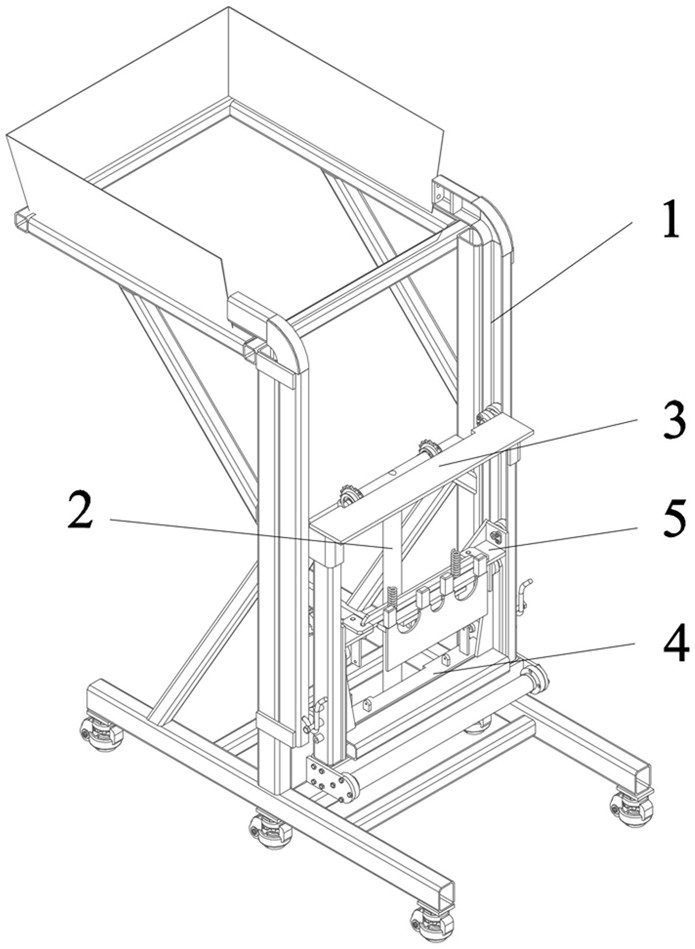

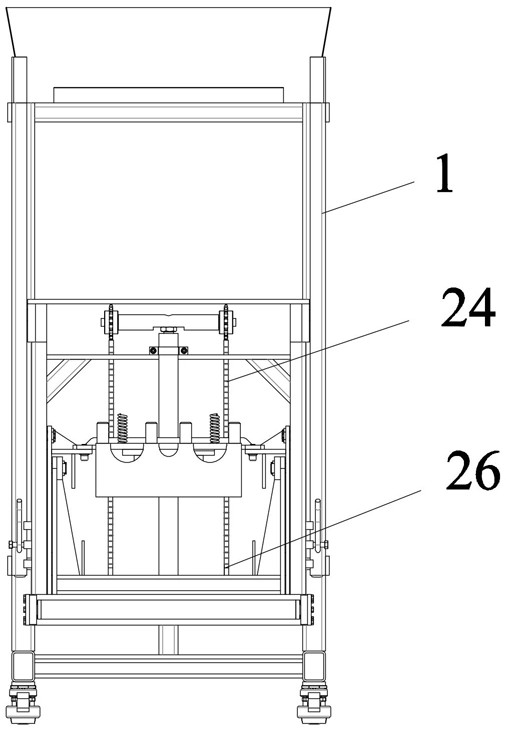

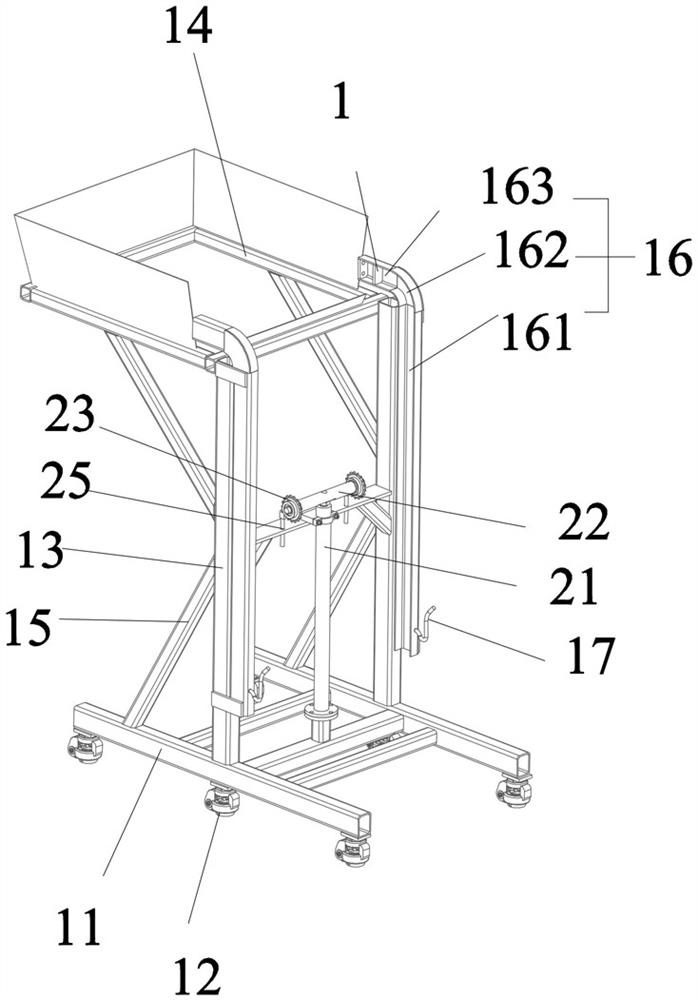

[0030] Embodiment one, such as Figure 1-7 As shown, a garbage can lifting device with a weighing function includes: a main frame 1, the main frame is adapted to be installed on a garbage truck, so as to dump garbage into the garbage truck; a lifting mechanism 2 is used to lift the garbage can Lift and turn over; the pressing plate mechanism 3 is used to press the opening of the garbage can to avoid the garbage can from being completely turned into the garbage truck when dumping; the turning mechanism 4 is used to support the pressing plate mechanism when turning the garbage can, so that The angle of the garbage can is changed; the weighing mechanism 5 is used to weigh the garbage can when the garbage can is raised.

[0031]Described main frame comprises base 11, and castor 12 is installed on the underside of described base, and described base is provided with two vertical vertical beams 13, is connected with rectangular fixed frame 14 above described vertical beams, and descr...

Embodiment 2

[0038] Embodiment two, such as Figure 8 , 9 As shown, the difference between this embodiment and Embodiment 1 is that the idler mechanism 6 is installed on the lower part of the platen mechanism, and the idler mechanism includes an idler mounting seat 61 and an idler roller 35, and the idler mounting seat rotates Connected to the lower part of the platen mechanism, the first transmission wheel 62 is also installed on the roller mounting seat, the first transmission wheel drives the roller mounting seat to rotate, and the second transmission wheel is also installed on the turning mechanism 63. When the overturning mechanism rotates relative to the weighing mechanism, the second transmission wheel rotates accordingly, and the axis center of the idler roller is set eccentrically relative to the rotation axis of the idler mounting seat; the weighing mechanism is provided with There is a first connecting rod seat 64, a second connecting rod seat 65 is arranged on the turning mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com