Powder pressing machine capable of scraping away powder on surface of grinding tool for eye shadow production

A powder press, eye shadow technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of pushing out, unable to scrape eye shadow powder, unable to automatically press eye shadow powder, etc., to improve production efficiency , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

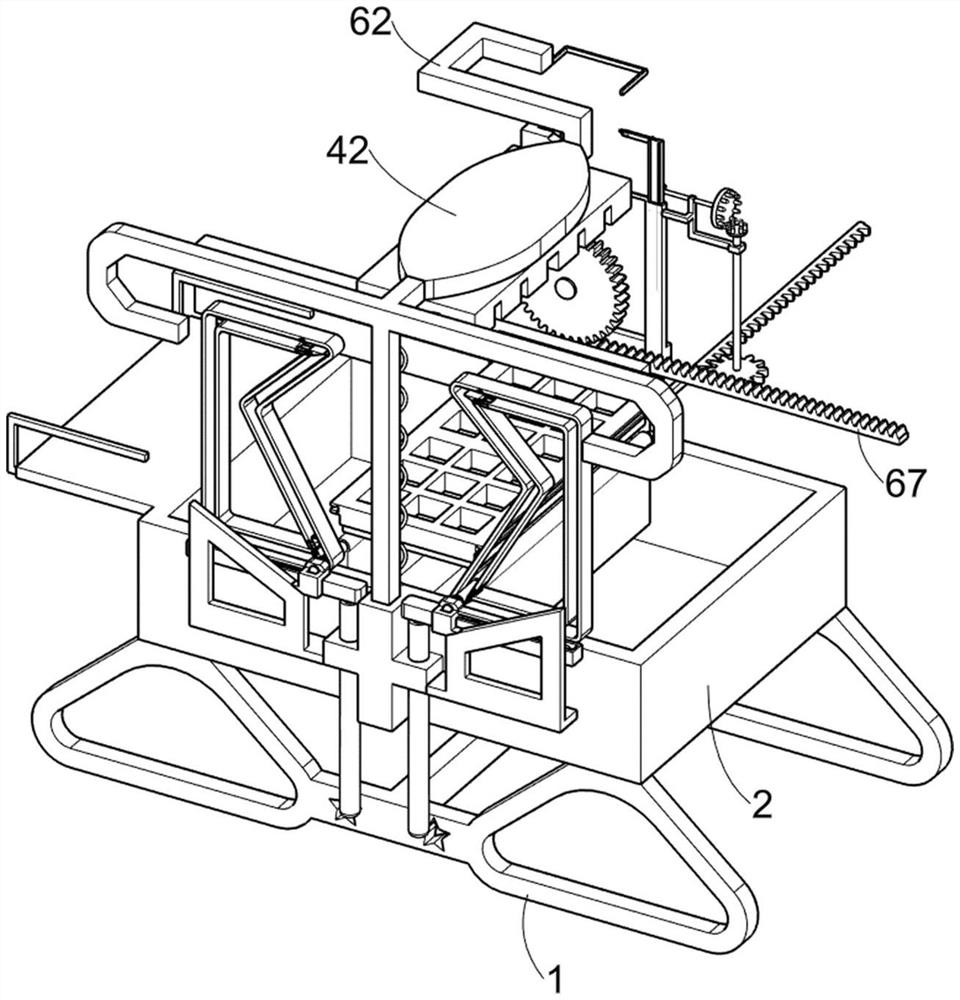

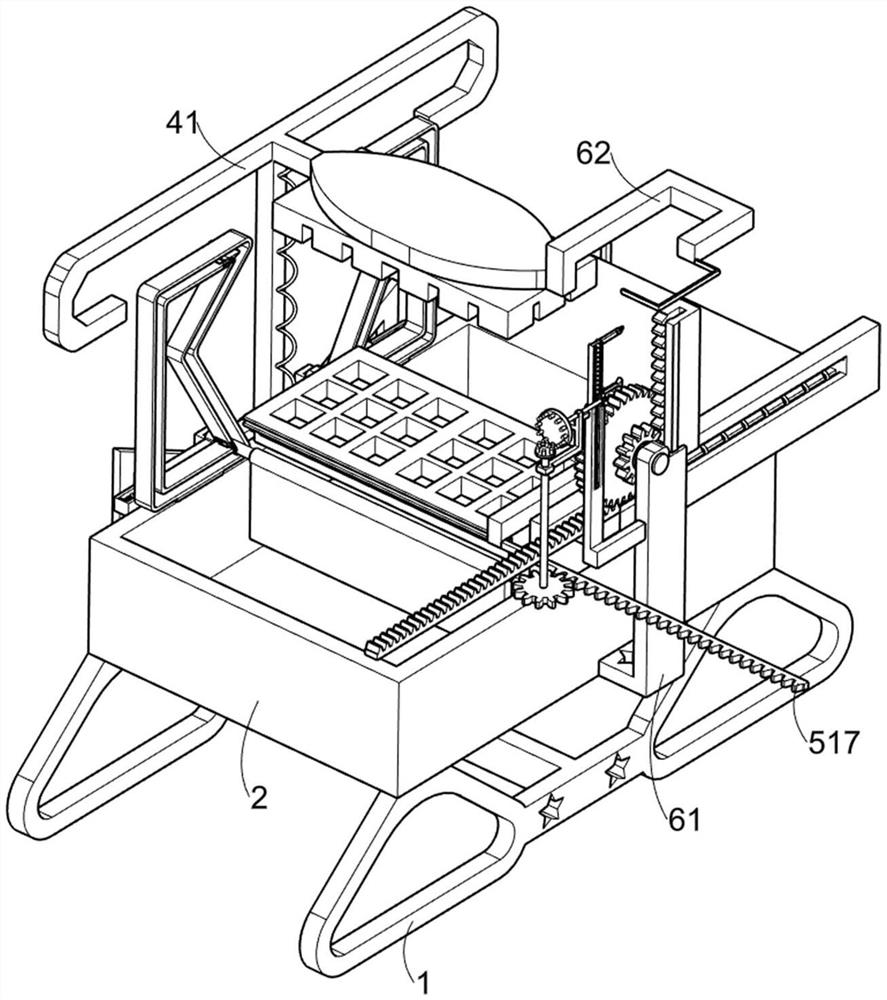

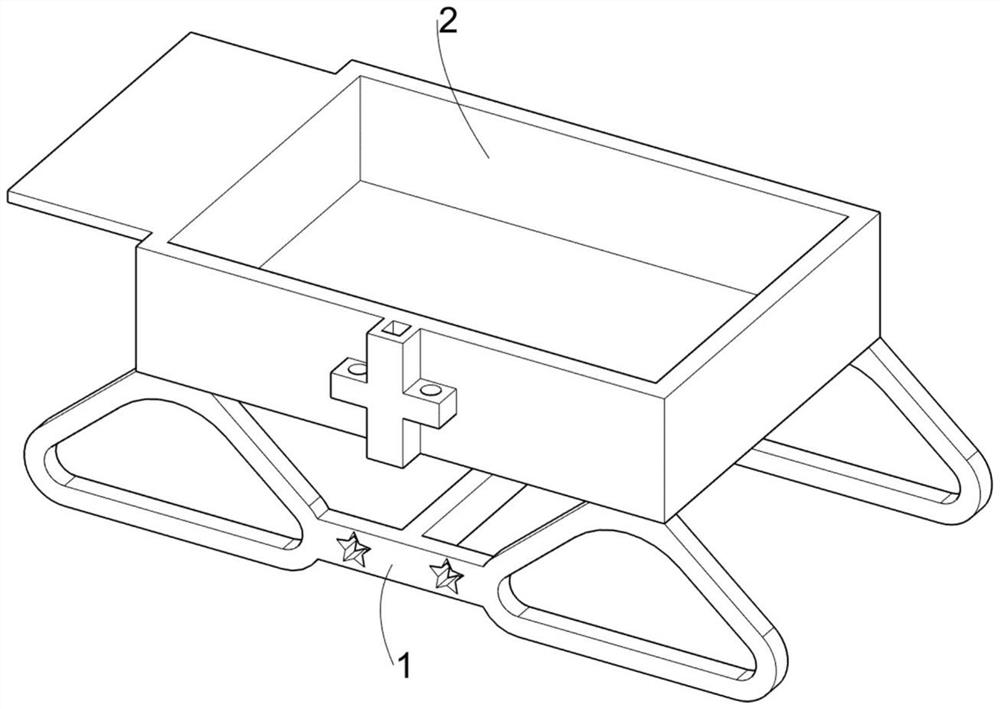

[0030] A compact powder machine for eye shadow production that can scrape off the powder on the surface of the abrasive tool, such as Figure 1-13 As shown, it includes a bottom frame 1, a special-shaped material box 2, a powder shovel mechanism 3, a powder pressing mechanism 4 and a powder scraping mechanism 5. The bottom frame 1 is connected with a special-shaped material box 2, and the powder shovel mechanism 3 is located on the special-shaped material box 2. Above, the powder shoveling mechanism 3 is used to pack the eye shadow powder, the powder pressing mechanism 4 is set on the special-shaped material box 2, the powder pressing mechanism 4 is used to compact the eye shadow powder on the slide 612, and the powder scraping mechanism 5 is set on the special-shaped material box 2. On the box 2, the powder scraping mechanism 5 is used to scrape off the eye shadow powder mounted on the abrasive plate 52.

[0031]Powder shoveling mechanism 3 comprises electric push rod 31, gro...

Embodiment 2

[0039] On the basis of Example 1, such as Figure 11-13 As shown, it also includes a push-out mechanism 6. The push-out mechanism 6 is arranged on the special-shaped material box 2. The push-out mechanism 6 is used to make the pressed eye shadow powder drop down to the special-shaped material box 2 for subsequent collection. The push-out mechanism 6 includes special-shaped opening bracket 61, special-shaped connecting rod 62, rotating shaft four 63, overrunning clutch 64, gear four 65, gear five 66, rack three 67, sixth return spring 68, rack frame 69, seventh return spring 610, separation rod 611, slide plate 612 and the eighth return spring 613, special-shaped opening support 61 is connected to the other side of special-shaped material box 2, special-shaped opening support 61 is connected with special-shaped slotting support frame 54, on the oval connecting plate 42 Be connected with special-shaped connecting rod 62, and special-shaped connecting rod 62 is used to push rack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com