Anti-dry-burning heating body of electric hot-water bag

An electric hot water bag and anti-dry technology, which is applied to the shape of heating elements, heating appliances for therapeutic treatment, cooling appliances for therapeutic treatment, etc. The quality and quality of the electric hot water bag are solved, and the structure is novel, the anti-dryness is better, and the effect is better.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

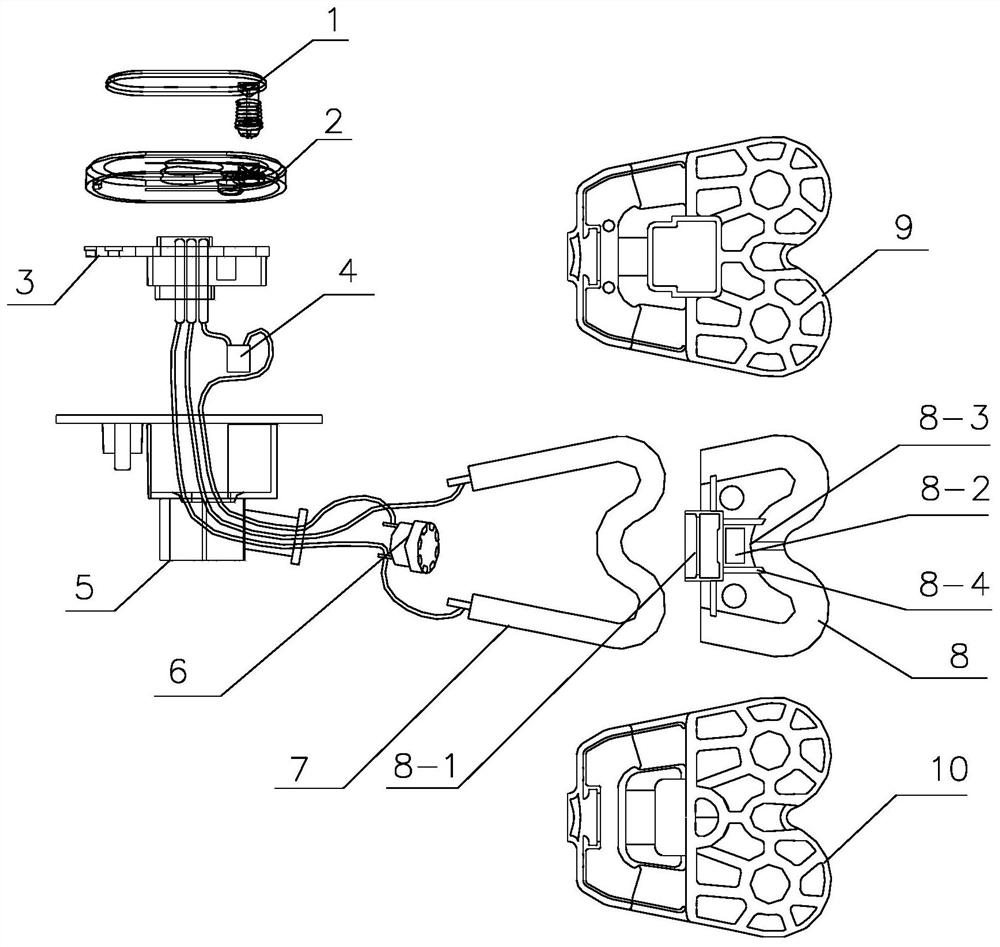

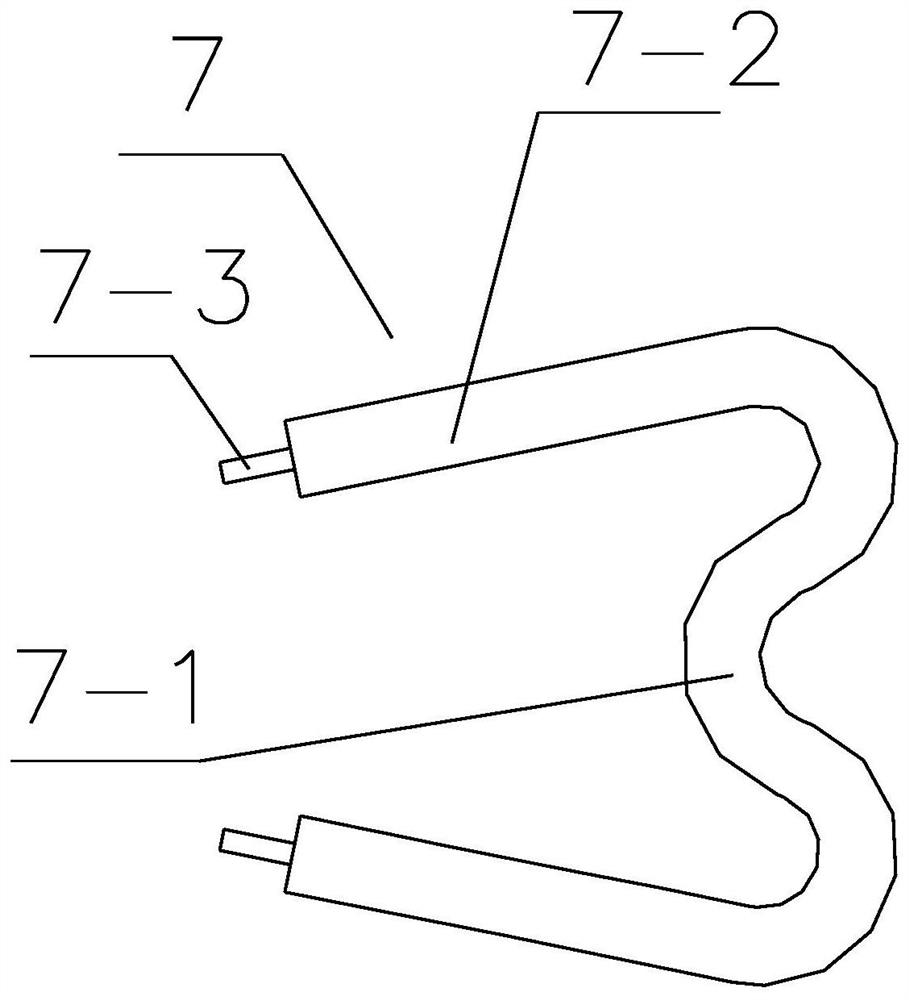

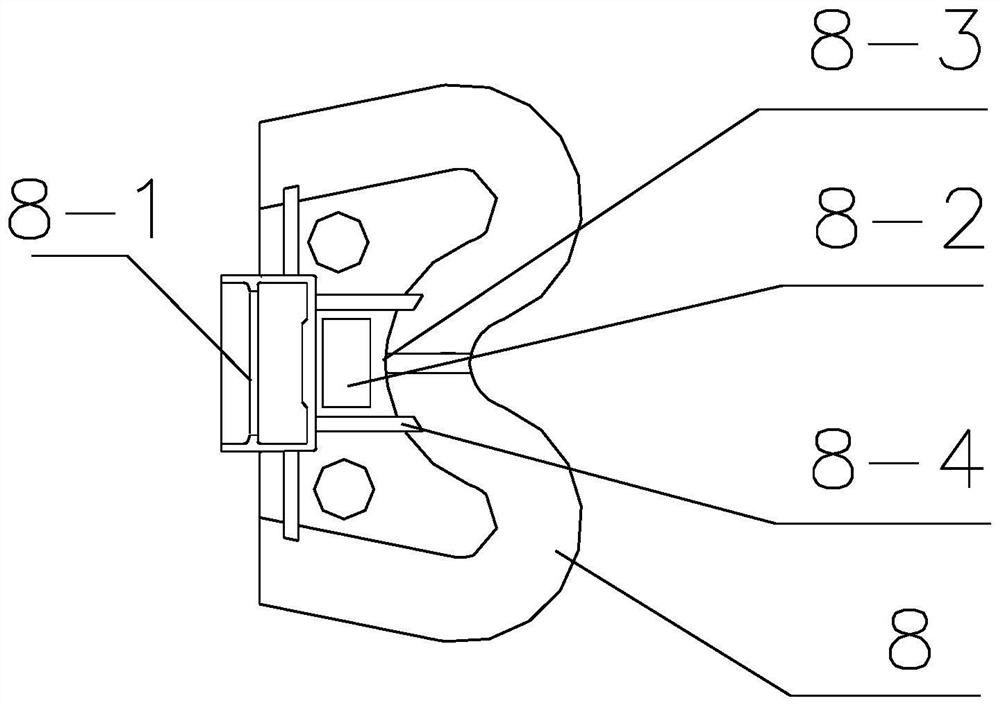

[0021] An anti-dry-boiling heating element of an electric hot water bag, comprising a heating tube 7, the outer aluminum of the heating tube 7 is die-casted with a coating layer 8. The slurry layer 8 is mainly wrapped around the outside of the middle section of the electric heating tube 7 .

[0022] In the technical solution of the present application, a slurry coating layer 8 is added outside the heat pipe 7, and the slurry coating layer 8 is made of aluminum. The contact area between the heating pipe 7 and the liquid in the electric hot water bag is increased, and the heating is faster and more uniform when heating up.

[0023] The heat pipe 7 is bent into a W-shaped structure. This structure prolongs the length of the heating pipe 7 in the limited space, while heating faster, the edge sets the high temperature point 8-3 in the middle close to the thermostat mounting seat 8-1.

[0024] A temperature controller mounting seat 8-1 is integrally formed on the slurry layer 8 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com