Internal circulation bidirectional heating integrated energy storage and heat release equipment

A two-way heating, energy storage and heat release technology, which is applied in lighting and heating equipment, heat storage equipment, heat storage heaters, etc., can solve the problems of unfavorable equipment recycling, large energy loss, and low heat energy conversion rate, etc., to improve Energy storage effect, full utilization of heat energy, and uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

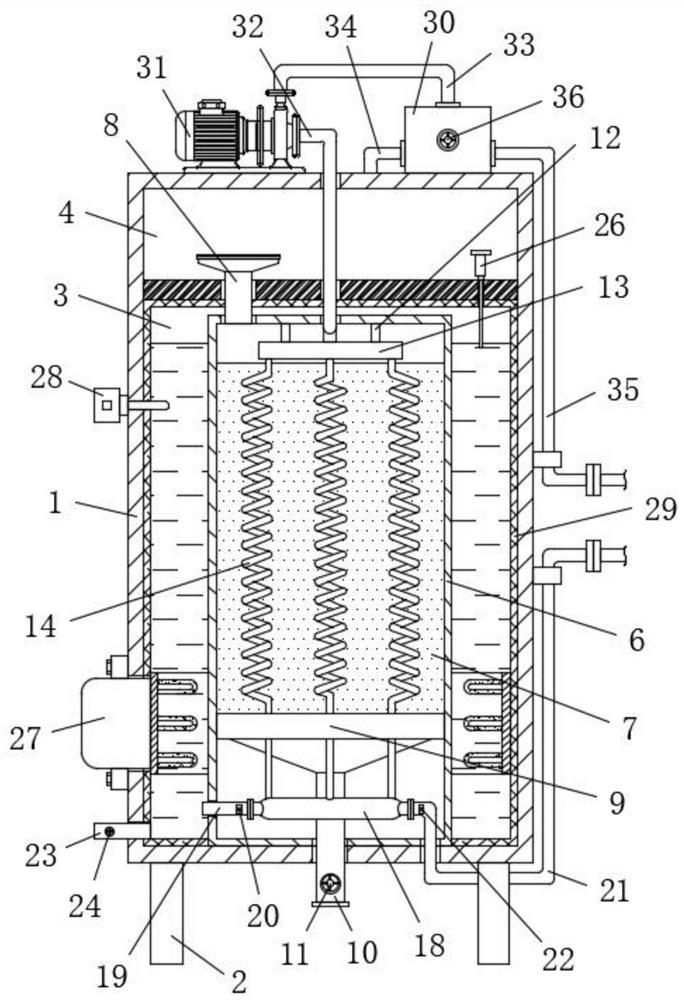

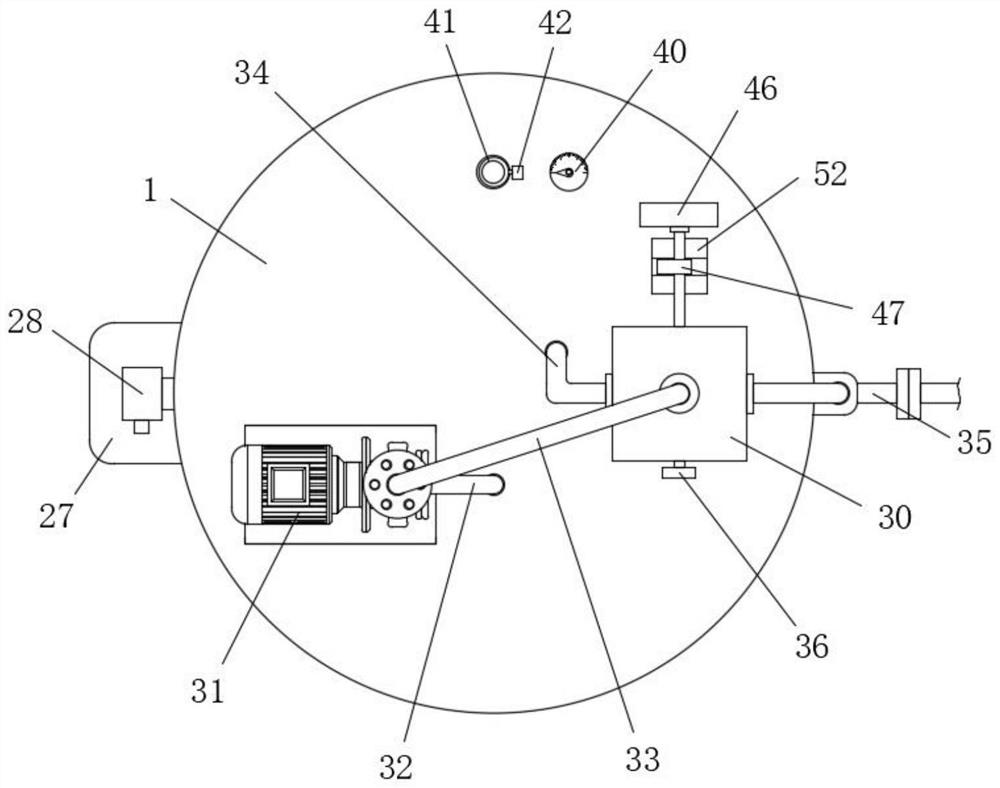

[0045] refer to Figure 1-Figure 13 , an internal circulation two-way heating integrated energy storage and heat release equipment, including a tank body 1, the bottom of the tank body 1 is annularly provided with four supporting legs 2, and the inside of the tank body 1 is respectively provided with a heating chamber 3 and a feeding chamber 4 And the preheating chamber 5, the feeding chamber 4 and the preheating chamber 5 are arranged side by side above the heating chamber 3, the bottom inner wall of the heating chamber 3 is fixedly connected with an energy storage box 6, and the interior of the energy storage box 6 is equipped with molten salt 7, and the storage The top of the energy tank 6 is provided with a feed hopper 8 extending into the feed chamber 4, a drain pipe 23 is provided at the bottom of one side of the tank body 1, a drain valve 24 is installed on the drain pipe 23, and a discharge valve 24 is installed in the energy storage tank 6. The discharge mechanism of ...

Embodiment 2

[0047] This embodiment is improved on the basis of embodiment 1: refer to Figure 1-Figure 14 , an internal circulation two-way heating integrated energy storage and heat release equipment, including a tank body 1, the bottom of the tank body 1 is annularly provided with four supporting legs 2, and the inside of the tank body 1 is respectively provided with a heating chamber 3 and a feeding chamber 4 And the preheating chamber 5, the feeding chamber 4 and the preheating chamber 5 are arranged side by side above the heating chamber 3, the bottom inner wall of the heating chamber 3 is fixedly connected with an energy storage box 6, and the interior of the energy storage box 6 is equipped with molten salt 7, and the storage The top of the energy box 6 is provided with a hopper 8 extending into the feeding chamber 4, and one side of the tank body 1 is provided with a door body 37 corresponding to the feeding chamber 4. Open the door body 37, and the energy can be stored through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com