Self-cleaning control method and device for air conditioner filter screen, medium and equipment

A control method and technology of a cleaning device, which are applied in the directions of space heating and ventilation control input, control input involving users/components, mechanical equipment, etc., can solve the complex self-cleaning process of the filter screen, the unreliable operation of the equipment, and the low cleaning efficiency. and other problems to achieve the effect of avoiding deformation or even damage, high degree of automation, and thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057]

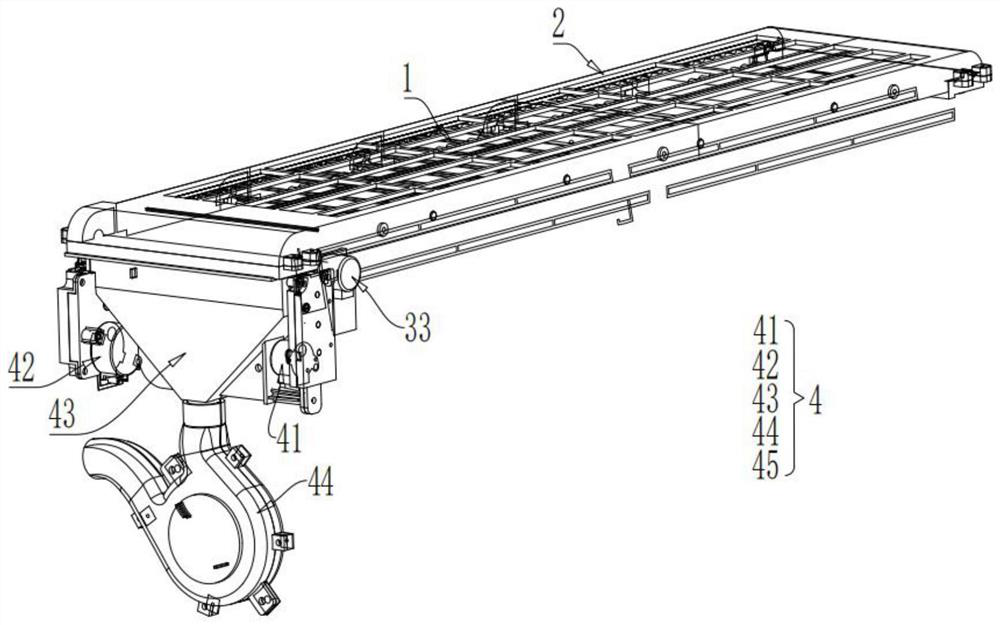

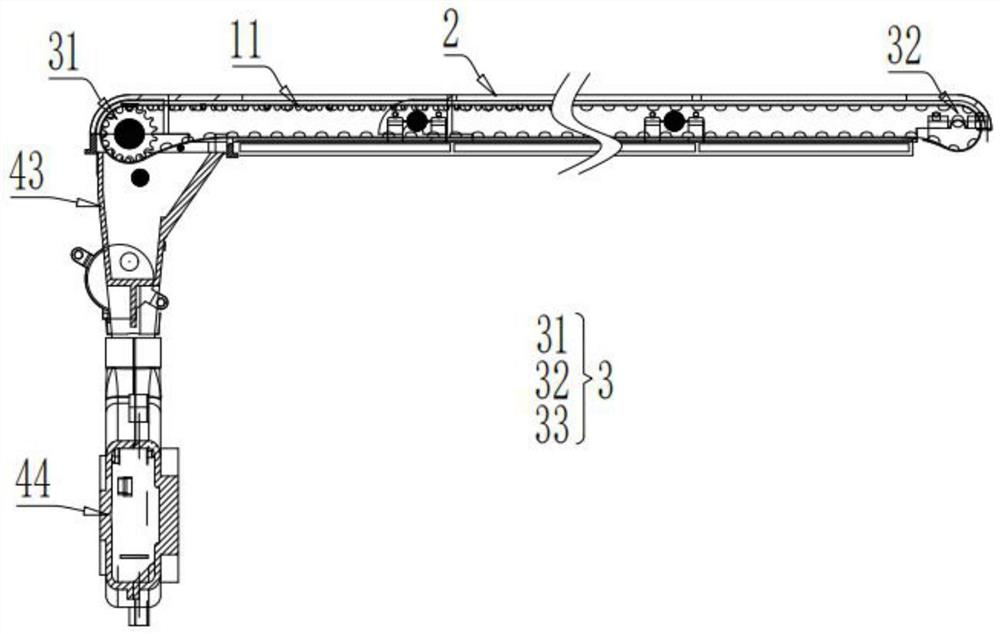

[0058] like Figure 2a , Figure 2b and Figure 2c As shown, the present embodiment provides a self-cleaning control method for an air conditioner filter. The air conditioner is provided with a cleaning device 4. The cleaning device 4 is provided with a vibrator 45. The vibrator 45 vibrates and cleans the filter screen 1. The control method is provided with a low Noise filter screen cleaning mode, the vibrator 45 is frequency conversion vibration under the low noise filter screen cleaning mode; specifically, the dust on the filter screen 1 is different from the contact mode of the filter screen 1 because of the difference in size and shape, and is different from the vibrator. The resonant frequency of 45 is different; when the vibrator 45 vibrates at a variable frequency, the frequency gradually increases in a certain interval, so that the resonant frequency of the dust on the filter screen 1 and the vibrator 45 is within this interval as much as possible, and then...

Embodiment 2

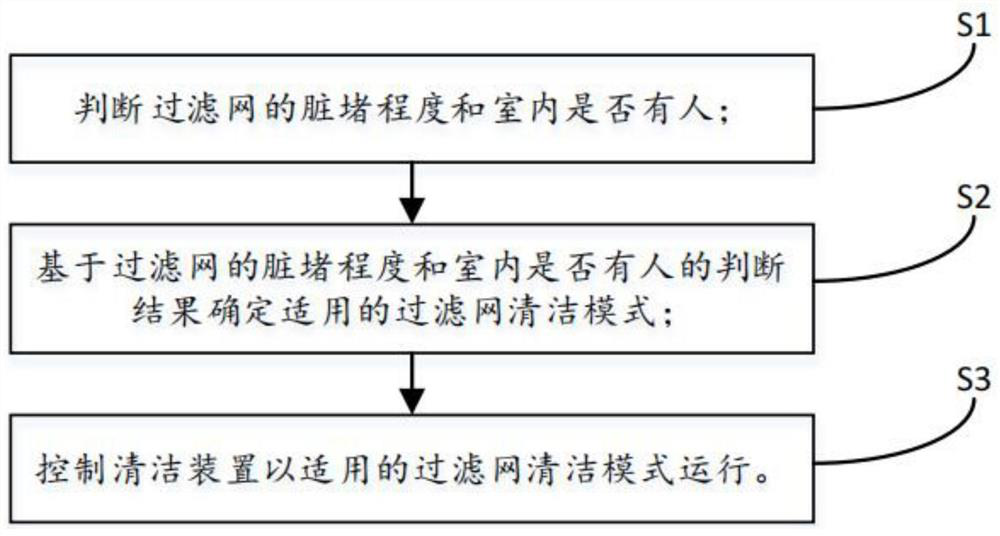

[0124] like image 3 As shown, this embodiment provides a self-cleaning control method for an air conditioner filter, and the air conditioner is the air conditioner in Embodiment 1; the control method includes:

[0125]S1. Start the air conditioner, and the light transmittance detection part detects the light transmittance M of the filter screen 1 and transmits the detection data to the controller;

[0126] S2. The controller compares the transmittance M of the filter screen 1 with the first preset transmittance M1; when the transmittance M of the filter screen 1 is less than or equal to the first preset transmittance M1, skip to step S3; when the transmittance M of the filter screen 1 is greater than the first preset transmittance M1 and less than the second preset transmittance M2, skip to step S4;

[0127] Preferably, the first preset transmittance M1=98%, and the second preset transmittance M1=99%;

[0128] S3, the infrared sensor detects the indoor situation and transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com