Air pulverized-coal adjusting system constructed on basis of intelligent power plant

A technology for regulating systems and power plants, applied in combustion equipment, lighting and heating equipment, block/powder supply/distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

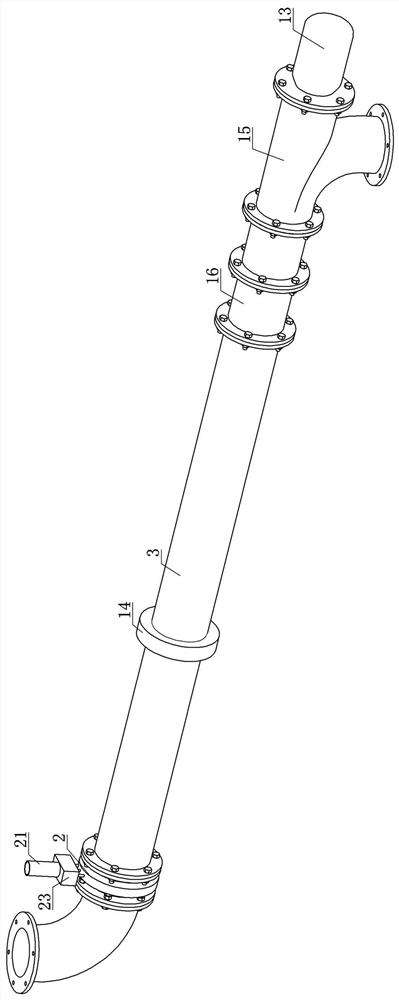

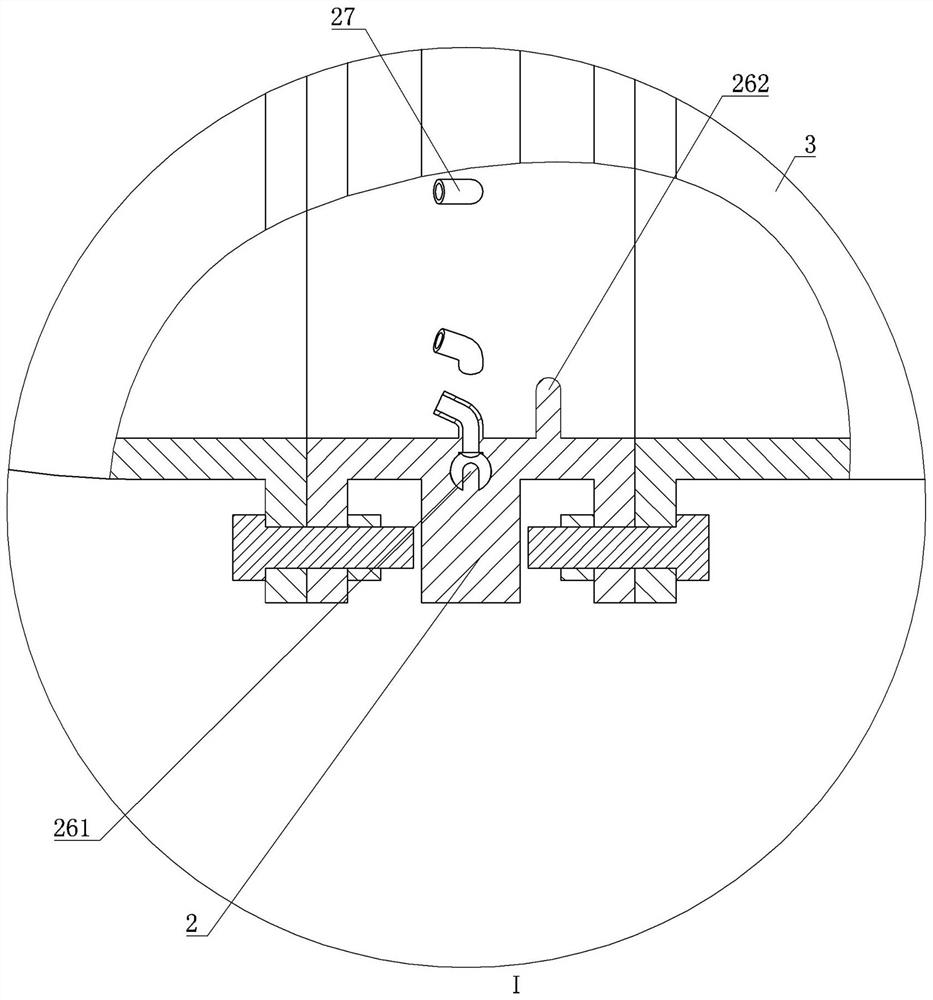

[0031] Example: see Figure 1-12 , an air powder regulating system based on the construction of a smart power plant, which is applied to the powder pipe from the same coal mill to the coal-fired boiler, including air speed control components and anti-blocking devices;

[0032] The wind speed control component is set in the horizontal section of the powder pipe, including the fan installed in the powder pipe, the rotating shaft connected to the fan, the frequency conversion motor connected to the output end and the end of the rotating shaft, and the online wind speed measuring device; the air flow from the fan rotates and the powder pipe The internal pulverized coal has the same wind direction, which will not increase the internal resistance of the powder pipe. At the same time, the airflow from the fan rotation will remix the pulverized coal to improve the accuracy of the pulverized coal. In addition, the fan accelerates the pulverized coal, and the speed The loss is supplemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com