Prestressed construction process for building high-rise building structure

A technology for high-rise buildings and construction technology, which is applied in the processing of building components, building structures, building materials, etc., can solve problems such as affecting the service life of high-rise buildings, and achieve good results, simple construction process steps, and uniform stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

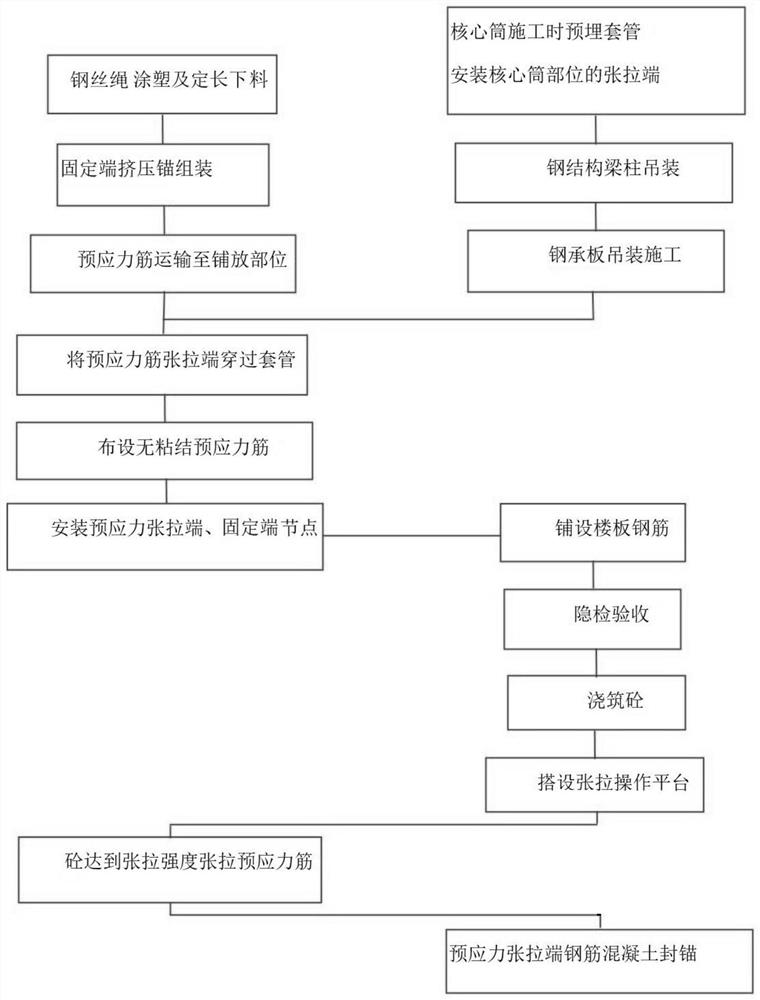

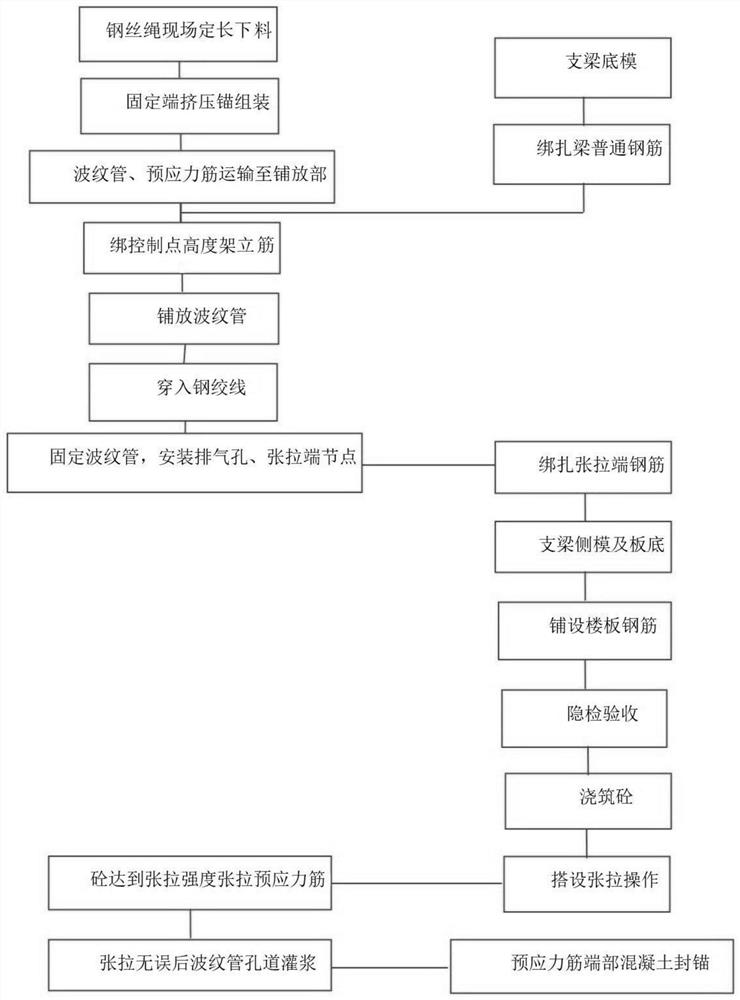

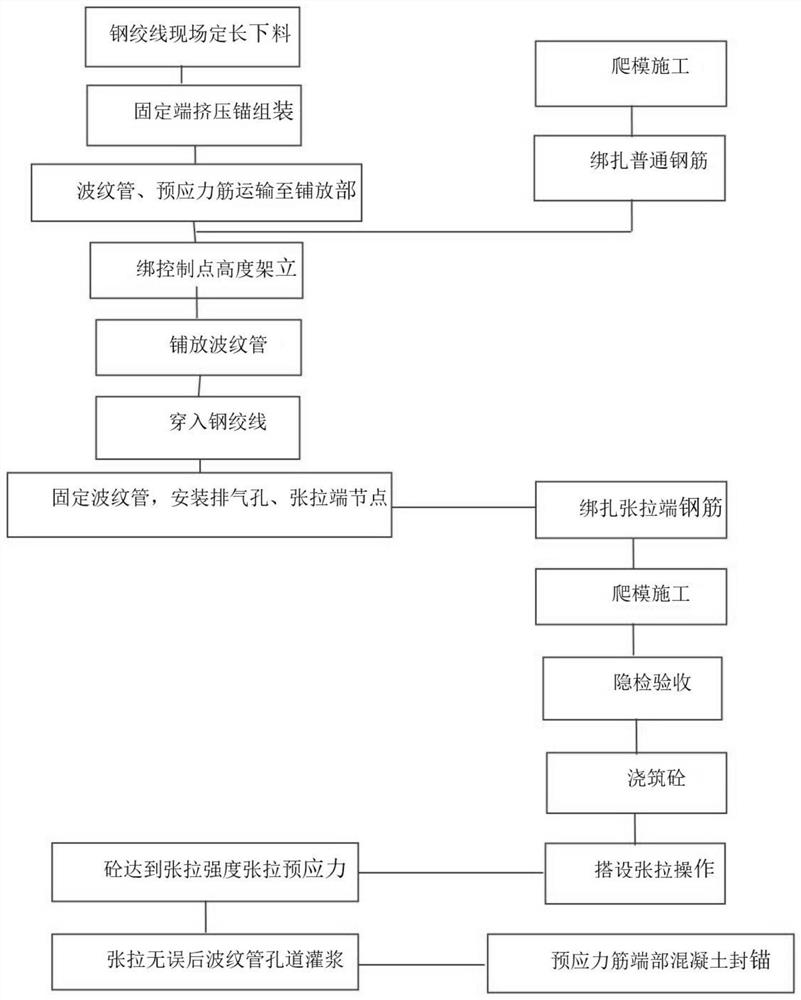

[0041] like Figure 1 to Figure 8 Shown, a kind of prestressed construction technology that is used for building high-rise building structure of the present invention comprises the following steps:

[0042] A. Processing, transportation and storage of prestressed tendons:

[0043] The prestressed steel wire rope 1 is first transported to a professional production workshop for processing. According to the size and quantity of the bill of material, each tension end of each prestressed steel wire rope 1 is designed with the reserved tension length and curve increase length for blanking. The steel wire rope 1 should be cut with a grinding wheel cutting machine, and electric welding and gas welding are strictly prohibited.

[0044] During the hoisting of unbonded prestressed tendons and accessories, avoid collision and extrusion as much as possible. When transporting, they should be transported in reels, and should be loaded and unloaded lightly. It is strictly forbidden to throw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com