Vaccine cold storage packaging paper and preparation method thereof

A technology for wrapping paper and vaccines, applied in the field of papermaking, can solve the problems of easy water absorption and dampness of paper, and achieve the effects of enhancing water resistance, inhibiting reproductive ability, and reducing hydrophilic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

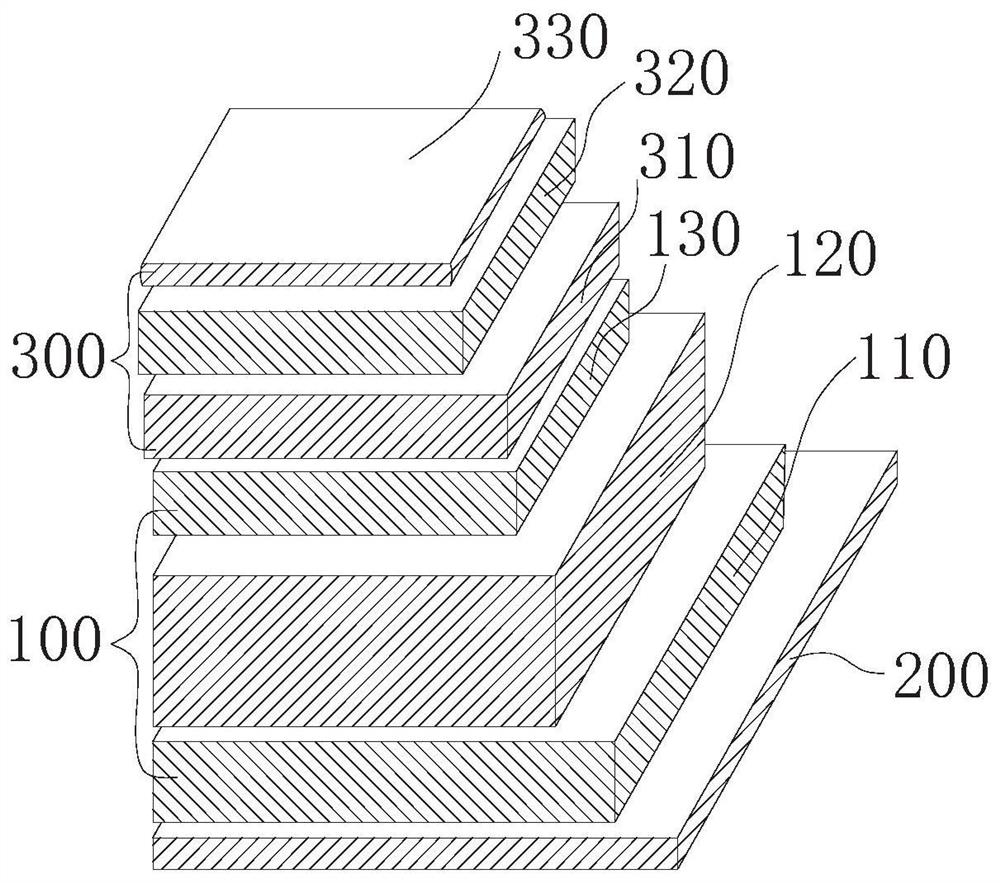

[0051] A vaccine refrigerated wrapper, such as figure 1 As shown, it includes a base paper layer 100 and a coating layer 300 and a back coat layer 200 coated on the upper surface and the lower surface of the base paper layer respectively, wherein: the base paper layer includes face paper layers stacked in sequence from top to bottom 130, a core paper layer 120 and a bottom paper layer 110;

[0052] The preparation technology of this vaccine refrigerated packaging paper comprises the following steps:

[0053] (1) pulping process

[0054] Face paper layer: The pulp composition of the face paper layer is 100% bleached chemical pulp. After the pulp board is disintegrated by a hydraulic pulper according to a certain ratio, it is screened, beaten, and pulped, and finally sent to the paper machine for papermaking.

[0055] Core paper layer: The pulp composition of the core paper layer is 50% bleached chemical mechanical pulp and 50% bleached chemical pulp. paper machine for copyin...

Embodiment 2

[0075] A vaccine refrigerated packaging paper, comprising a base paper layer and a coating layer and a back coating layer respectively coated on the upper surface and the lower surface of the base paper layer, wherein: the base paper layer includes face paper layered sequentially from top to bottom Layer, core paper layer and bottom paper layer; coating layer includes top coat, core coat and precoat from top to bottom.

[0076] The preparation technology of this vaccine refrigerated packaging paper comprises the following steps:

[0077] (1) pulping process

[0078] Face paper layer: The pulp composition of the face paper layer is 100% bleached chemical pulp. After the pulp board is disintegrated by a hydraulic pulper according to a certain ratio, it is screened, beaten, and pulped, and finally sent to the paper machine for papermaking.

[0079] Core paper layer: The pulp composition of the core paper layer is 55% bleached chemical mechanical pulp and 45% bleached chemical pu...

Embodiment 3

[0099] A vaccine refrigerated packaging paper, comprising a base paper layer and a coating layer and a back coat layer respectively coated on the upper surface and the lower surface of the base paper layer, wherein: the base paper layer includes face paper layered sequentially from top to bottom Layer, core paper layer and bottom paper layer; coating layer includes top coat, core coat and precoat from top to bottom.

[0100] The preparation technology of this vaccine refrigerated packaging paper comprises the following steps:

[0101] (1) pulping process

[0102] Face paper layer: The pulp composition of the face paper layer is 100% bleached chemical pulp. After the pulp board is disintegrated by a hydraulic pulper according to a certain ratio, it is screened, beaten, and pulped, and finally sent to the paper machine for papermaking.

[0103] Core paper layer: The pulp composition of the core paper layer is 53% bleached chemical mechanical pulp and 47% bleached chemical pulp....

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com