All-dimensional rotary polishing mechanism for metal tool

A metal tool and polishing mechanism technology, which is applied in metal processing equipment, surface polishing machine tools, manufacturing tools, etc., can solve the problems of uneven oiling on the surface, affecting the polishing effect, uneven polishing of the sleeve surface, etc., and achieves high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

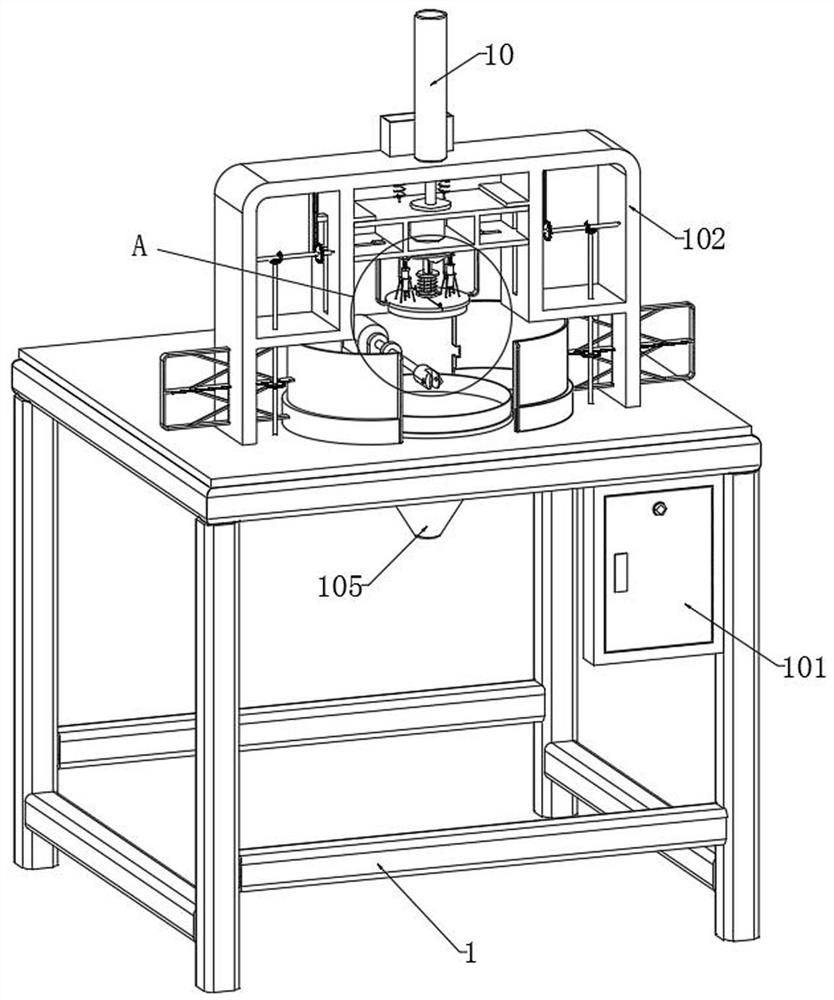

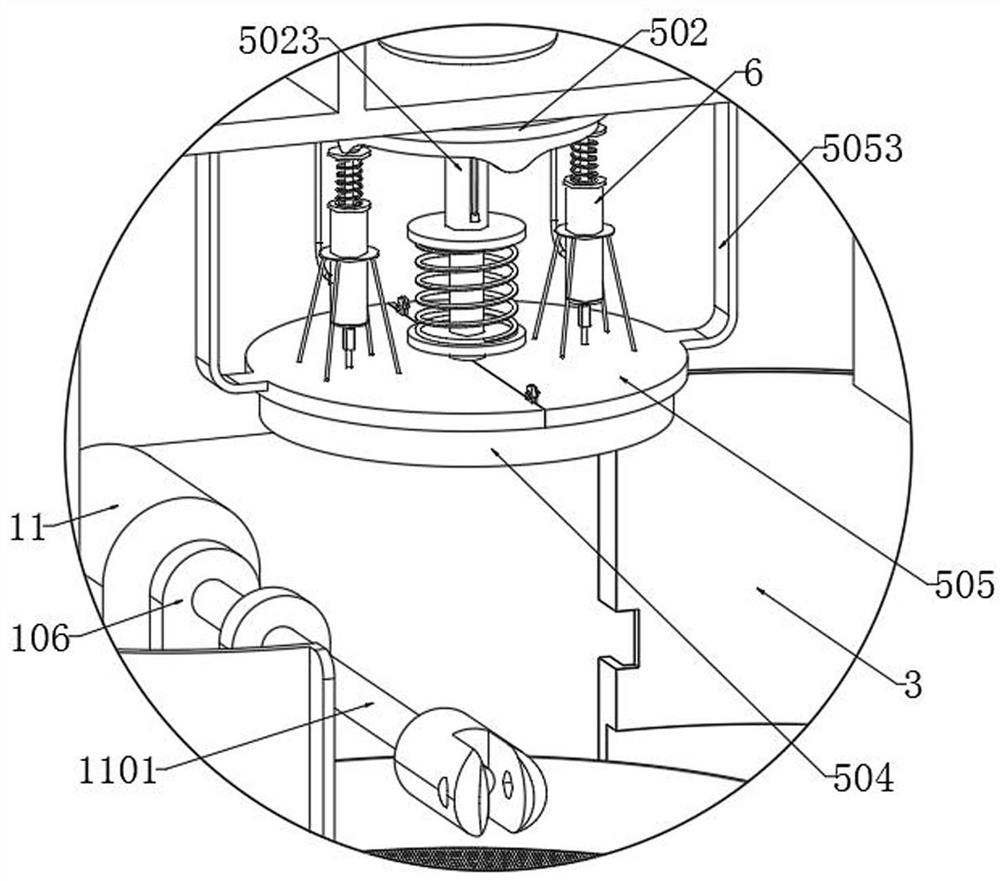

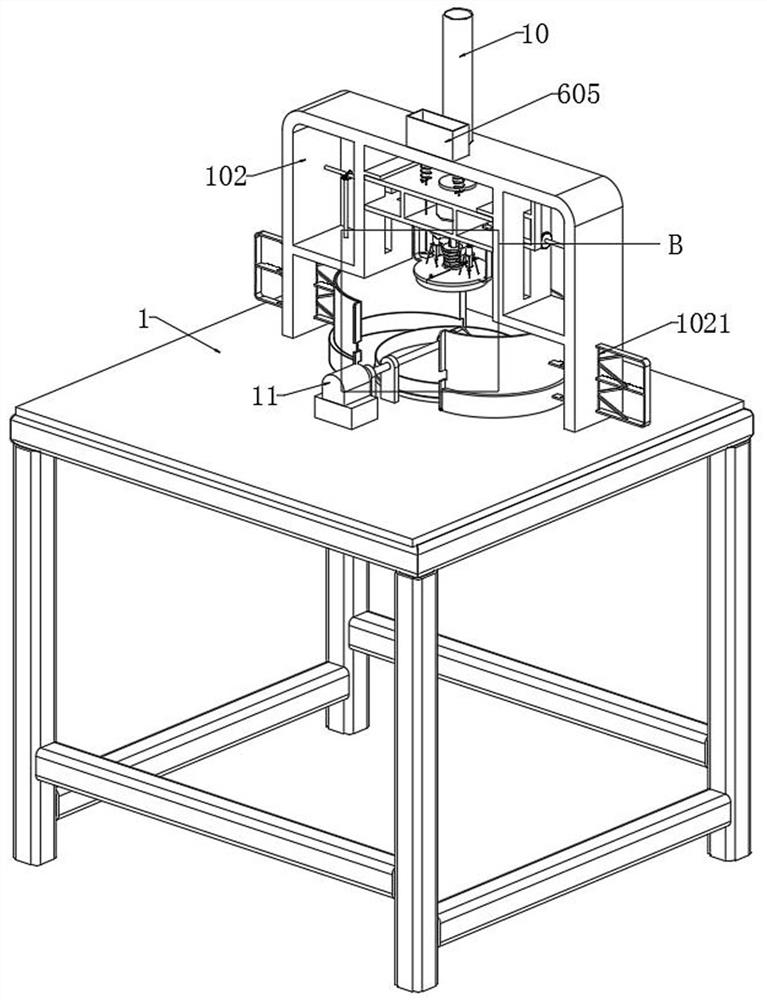

[0062] as attached figure 1 to attach Figure 15 Shown:

[0063] The present invention provides an omnidirectional rotary polishing mechanism for metal tools, including a frame 1;

[0064] A control box 101 is installed on the frame 1, and an upper support frame 102, a retaining ring 103 and a support plate 106 are fixedly connected to the top plate of the frame 1, and the lower ends of both sides of the upper support frame 102 are respectively provided with king-shaped grooves 1021, The upper ends of both sides of the interior are respectively provided with an L-shaped structure, and the L-shaped structure is provided with a vertical chute 1022 and a limit plate 1023; Three groups of fan-shaped holes 104 are also provided on the top plate, and a cone bucket 105 is also provided on the bottom side of the three groups of fan-shaped holes 104;

[0065] refer to Figure 8 A set of horizontal linkage shafts A7 and a set of vertical linkage shafts 9 on the left side are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com