Fabrication of aquaporin-based biomimetic membrane

A water channel and protein technology, applied in membrane, membrane technology, semi-permeable membrane separation, etc., can solve the problems of easy damage and unprotected water channel protein.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

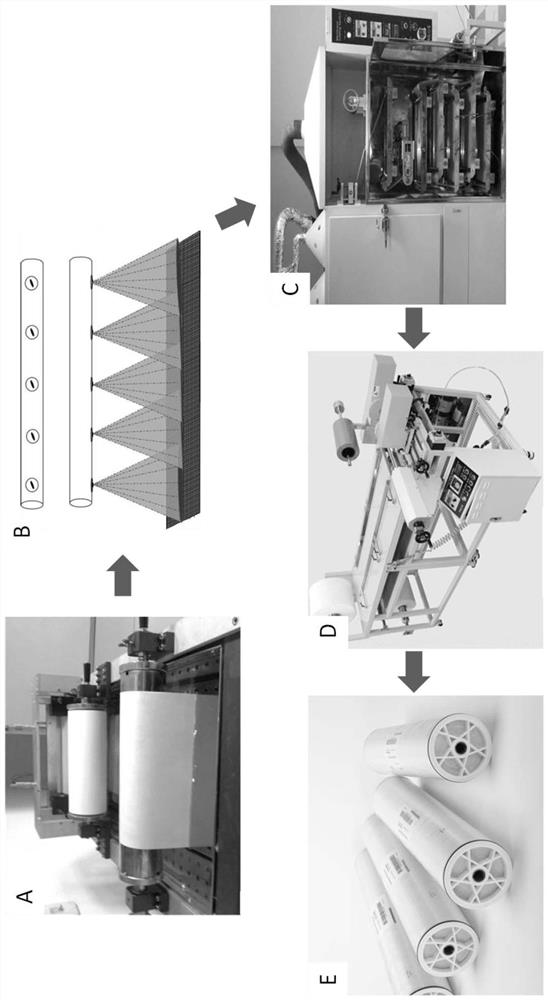

[0090] Example 1A: System Overview

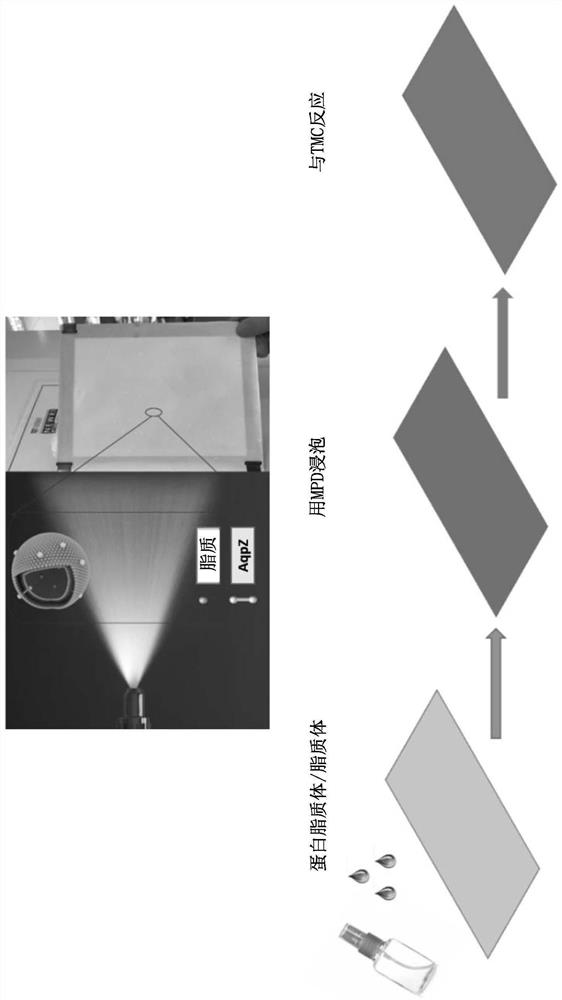

[0091] The present disclosure describes a method of producing interfacially polymerized ABMs in a cost-effective manner compared to conventional methods. A scheme describing this method is shown in figure 1 .

[0092] The proteoliposome solution is sprayed on the surface of the membrane substrate before soaking the membrane substrate or the surface of the membrane substrate in the aqueous monomer solution. After drying with nitrogen, the surface was exposed to an aqueous monomer solution for a certain period of time, followed by an organic phase polymerization procedure. Compared with membranes obtained by conventional interfacial polymerization methods, this spray method can be easily scaled up and consumes less aquaporin (AQP) to obtain membranes with similar performance. This demonstrates the great potential of the present method in reducing the overall cost of ABM production.

[0093] Flat-sheet ABM scale-up can be achieved by modif...

Embodiment 1B

[0094] Example 1B: Materials and chemicals

[0095] In various examples and embodiments disclosed herein, the following materials are used as non-limiting examples to demonstrate the present methods, membranes and systems.

[0096] Use 1,2-dioleoyl-sn-glycero-3-phosphorylcholine (DOPC, 20 mg / ml, Avanti Polar Lipids, Alabama, USA) as lipid to incorporate aquaporin (AQP) protein (i.e. water channel proteins). Aquaporins can be produced according to conventional methods. DOPC lipids were rehydrated using a buffered solution (phosphate-buffered saline (ie, PBS solution) with a pH of approximately 7.4). During proteolipid reconstitution, n-octyl-b-D-glucopyranoside (OG, ultrapure grade, Merck, Germany) was removed using Biobeads (Bio-rad laboratories, USA). For proteoliposome characterization, analytical grade sodium chloride (NaCl) with a purity greater than 99% was purchased from Merck (Germany) and used for stopped-flow testing. All solutions were prepared using Deionized (D...

Embodiment 2A

[0098] Embodiment 2A: proteoliposome preparation

[0099] DOPC proteoliposomes can be prepared as follows.

[0100] Briefly, 10 mg of DOPC liposomes were dried by nitrogen gas and then stored in a vacuum desiccator for at least 12 hours. A PBS buffer solution containing 1 wt% OG dissolved the dried liposomes together with a certain amount of AQP. The final volume was 1 ml. The solution was freeze-thawed 3 times and extruded 21 times using a 400 nm filter (Avestin extruder, Avestin, Canada). Then, add biobeads to the solution and vortex for at least 3 h to remove OG. Finally, the solution (containing the proteoliposomes) was extruded 11 times using a 200 nm filter to obtain proteoliposomes of uniform size and distribution. Assuming that 10 mg of DOPC liposomes are present in 1 ml of the resulting proteoliposome solution, the final solution concentration is 10 mg / ml DOPC proteoliposomes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com