A prefabrication process for coil pins

A coil and pin technology, which is applied in the field of coil pin prefabrication, can solve the problems such as the collapse of the outer surface of the inductor, and achieve the effects of avoiding the collapse of the inductor, improving the yield rate, and enhancing the magnetic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

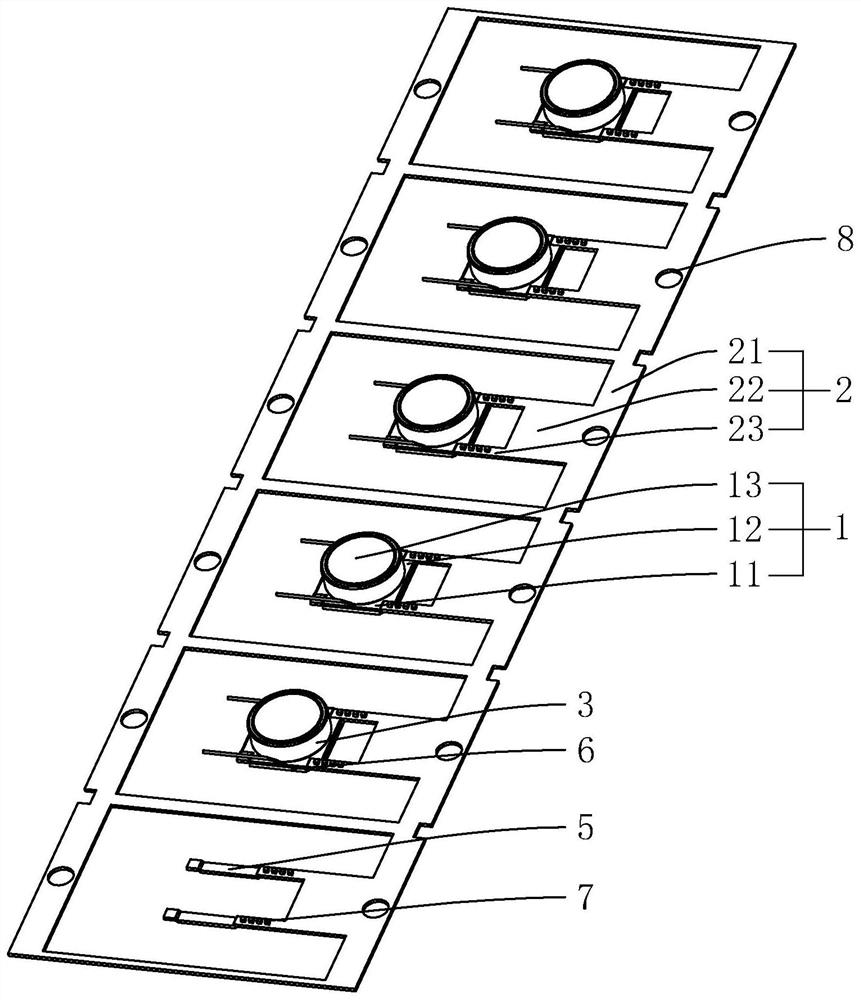

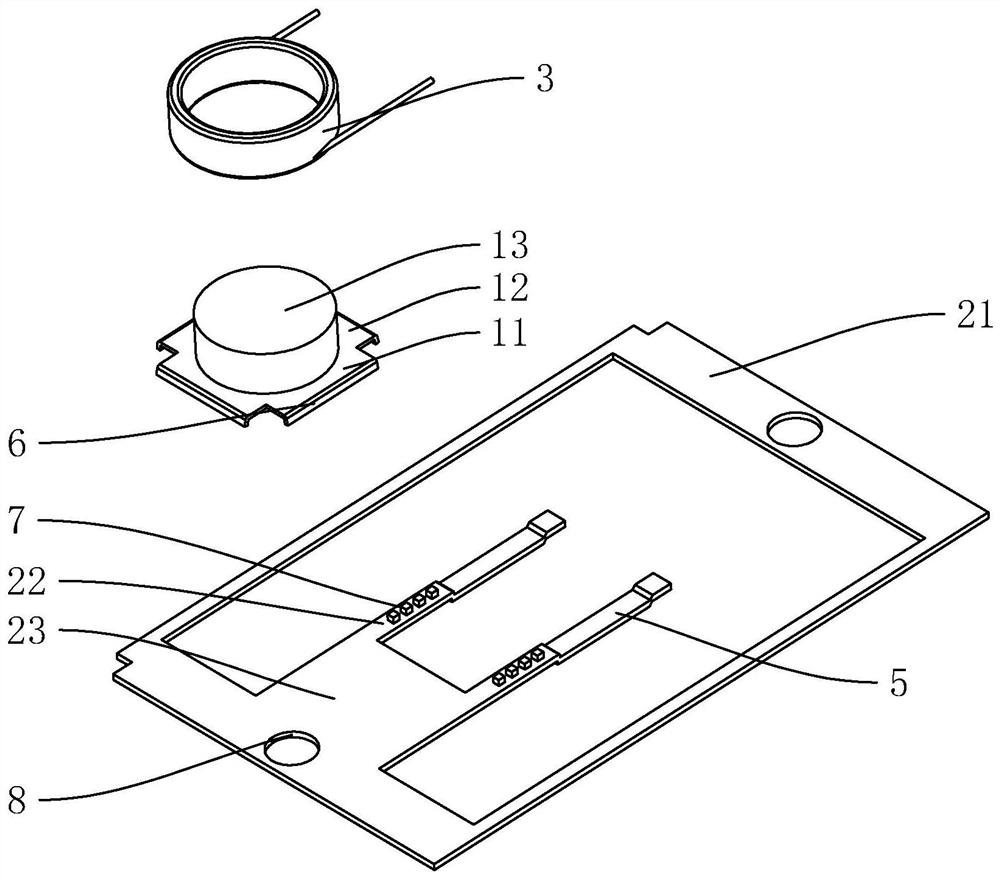

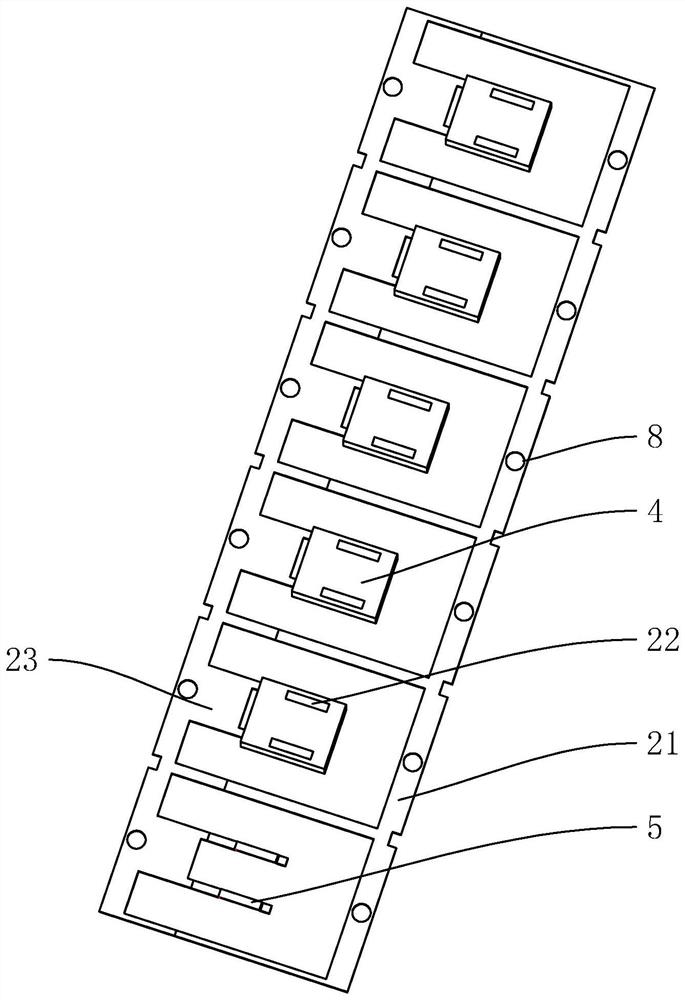

[0040] Attached to the following Figure 1-3 This application will be described in further detail.

[0041] The embodiment of the present application discloses a prefabrication process for coil pins. The prefabrication process of the coil pins includes the following steps:

[0042] S1, prefabricated T buckle 1 and carrier tape 2:

[0043] refer to figure 1 and figure 2 , put the metal plate into the corresponding punching die, and punch out the carrier tape 2. The carrier tape 2 consists of a plurality of mutually spliced supporting frames 21, two connecting bars 22 arranged in each supporting frame 21 and The extension piece 23 used to connect the two connecting bars 22 and the inner side wall of the support frame 21 is composed. The support frame 21 is composed of two positioning bars which are parallel and opposite to each other, and are erected between the two positioning bars and used to separate adjacent ones. The support strips of the two extension sheets 23 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com