Prefabrication process of coil pin

A technology of coils and pins, which is applied in the prefabrication process of coil pins, can solve problems such as collapse and cracking of the outer surface of inductors, and achieve the effects of avoiding collapse of inductors, enhancing magnetic permeability, and enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

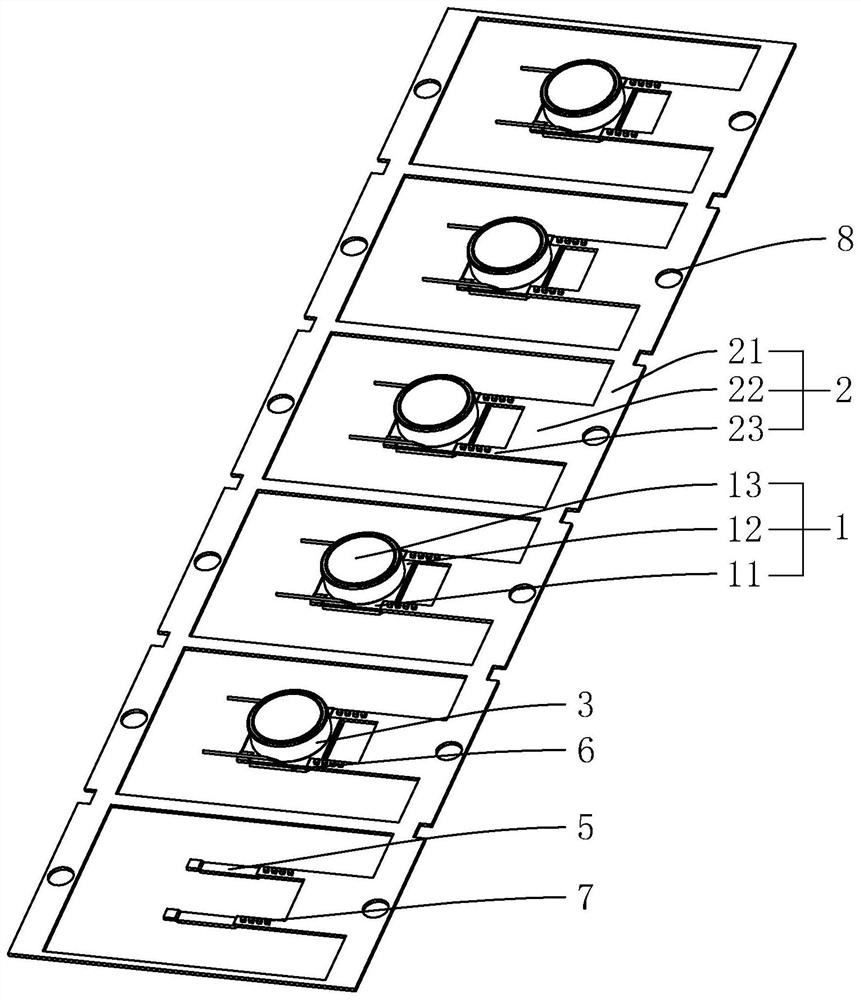

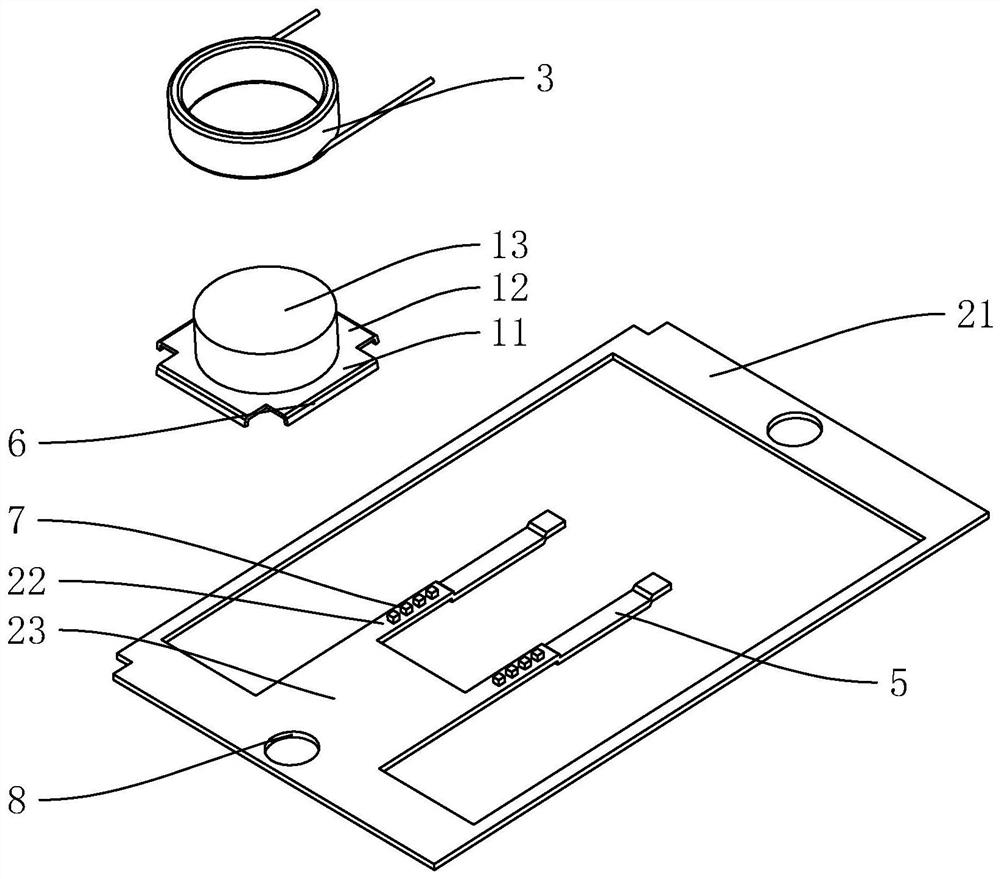

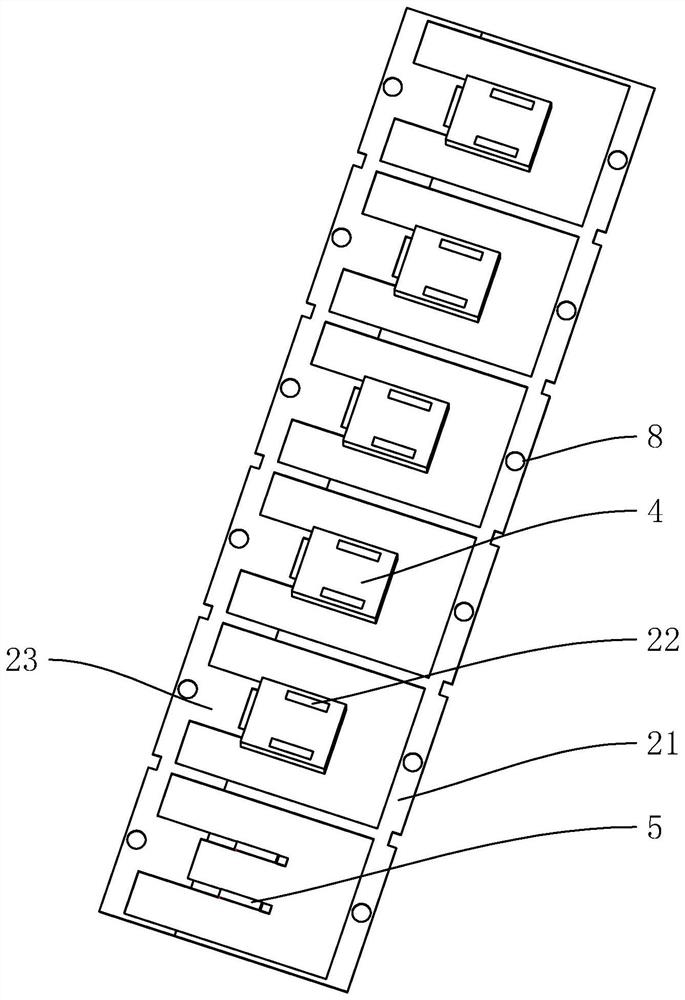

[0040] The following is attached Figure 1-3 The application is described in further detail.

[0041] The embodiment of the present application discloses a prefabrication process of a coil pin. The prefabrication process of the coil pins includes the following steps:

[0042] S1, prefabricated T buckle 1 and carrier tape 2:

[0043] refer to figure 1 and figure 2 , the metal sheet is put into the corresponding blanking die, and the carrier tape 2 is punched out. The carrier tape 2 consists of a plurality of supporting frames 21 spliced with each other, two connecting bars 22 arranged in each supporting frame 21 and It is used to connect two connecting bars 22 and an extension piece 23 on the inner side wall of the support frame 21. The support frame 21 is composed of two positioning bars that are parallel to each other and set opposite to each other, and are erected between the two positioning bars and are used to separate adjacent ones. The support strips of the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com