Aerospace current-carrying slip ring temperature rise modeling method based on multi-physics field coupling

A multi-physics and modeling method technology, applied in the field of temperature rise modeling of current-carrying slip rings for aerospace, can solve the problems of long operating life, inability to analyze the temperature of slip rings, and high cost of current-carrying slip rings for aerospace. Increases reliability, saves money and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, a method for modeling the temperature rise of a current-carrying slip ring for aerospace based on multi-physical field coupling of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings. elaborate.

[0053]

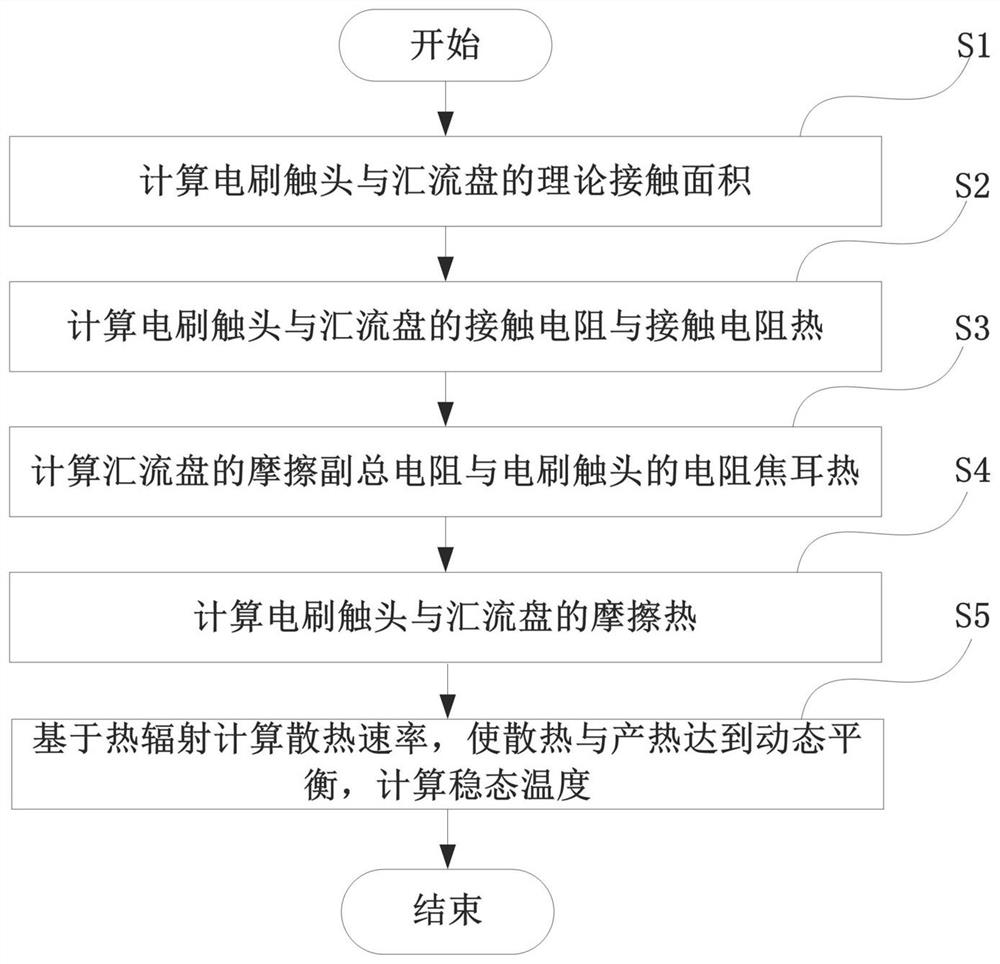

[0054] figure 1 It is a flow chart of the modeling method for the temperature rise of the aerospace current-carrying slip ring based on multi-physics field coupling in an embodiment of the present invention.

[0055] Such as figure 1 As shown, the method for modeling the temperature rise of aerospace current-carrying slip rings based on multi-physics coupling provided in this embodiment includes the following steps:

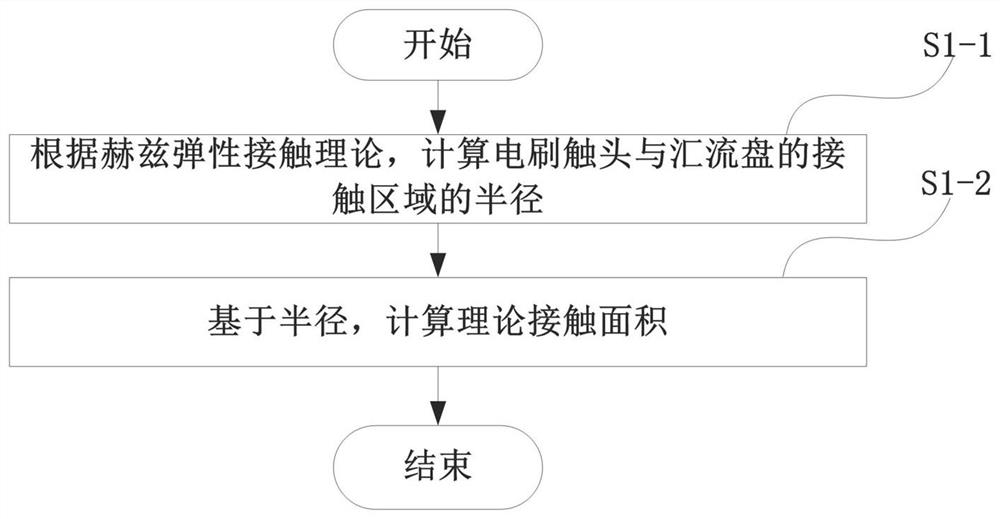

[0056] Step S1, calculating the theoretical contact area between the brush contact and the collector plate;

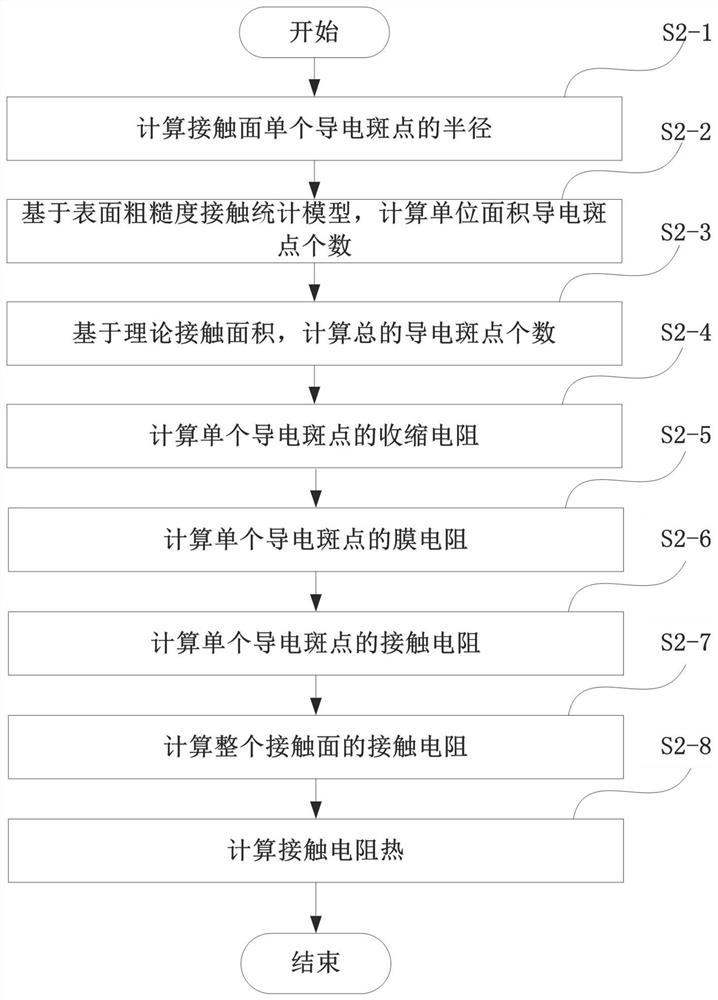

[0057] Step S2, calculating the contact resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com